Method for preparing nickel cobalt aluminum serving as cathodic material of lithium ion battery

A technology for lithium ion batteries and cathode materials, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of sintering temperature, harsh production conditions, and inability to achieve, and achieves low requirements for synthesis equipment, high degree of automation, The effect of less waste of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

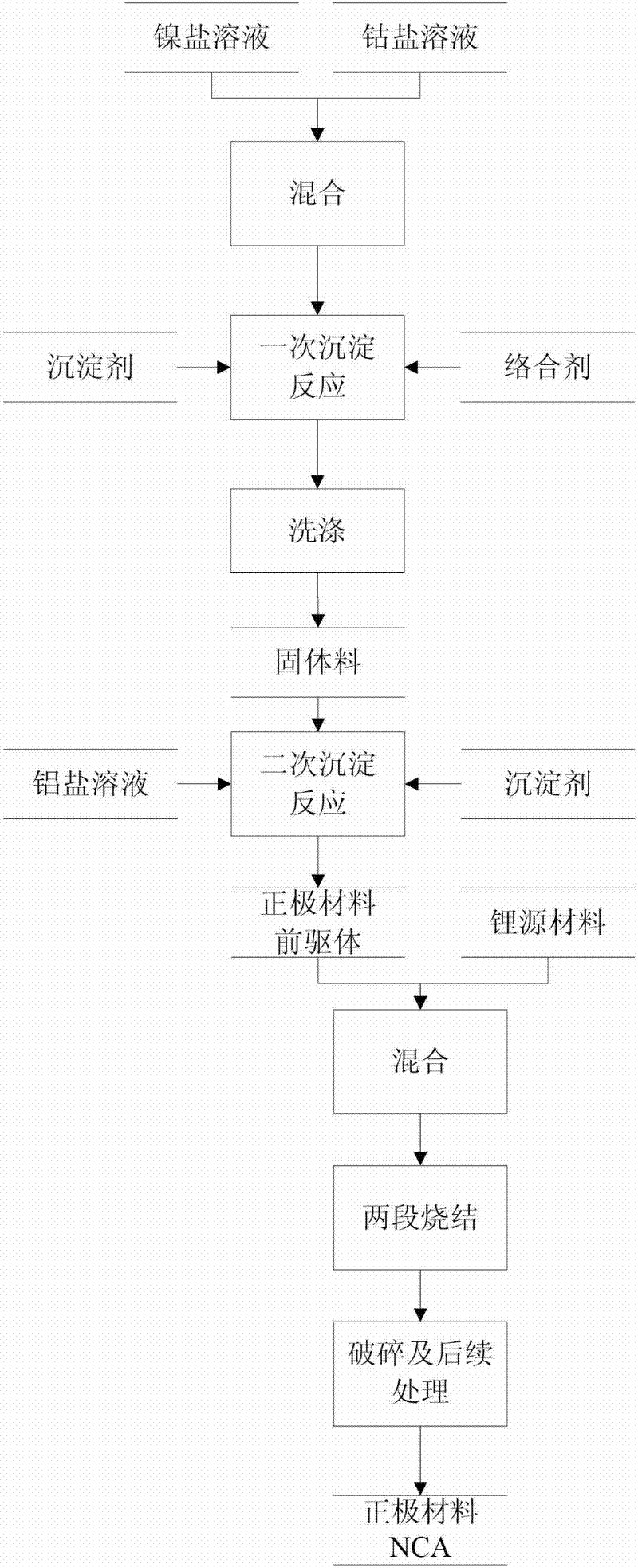

[0024] a kind of like figure 1 The preparation method of the shown lithium ion battery cathode material nickel-cobalt-aluminum of the present invention may further comprise the steps:

[0025] (1) Preparation of nickel-cobalt-aluminum precursor: Weigh nickel sulfate and cobalt sulfate crystals at a molar ratio of 8:2, dissolve them in water, and mix the nickel sulfate solution and cobalt sulfate solution evenly. The volume of the mixed solution is 6L, of which The metal ion concentration is 1.0M, and the nickel-cobalt mixed solution is fed into a reaction kettle with a volume of 10L in parallel with 14M ammonia solution and 2M sodium hydroxide solution (the feeding rate of the nickel-cobalt mixed solution is 0.6L / h) , the reaction kettle is filled with 1.0L bottom liquid (ammonia water) with a pH value of 11.5 and a temperature of 60°C, heated and stirred for a precipitation reaction; during a precipitation reaction, the pH value of the reaction system is controlled by sodium ...

Embodiment 2

[0029] a kind of like figure 1 The preparation method of the shown lithium ion battery cathode material nickel-cobalt-aluminum of the present invention may further comprise the steps:

[0030] (1) Step (1) of this embodiment is the same as step (1) of Embodiment 1;

[0031] (2) Preparation of nickel-cobalt-aluminum cathode material: mix the lithium-ion battery cathode material precursor prepared in the above step (1) with the lithium source lithium carbonate, and the molar ratio of the lithium-ion battery cathode material precursor to lithium carbonate is 1: 1.05, mixed evenly, placed in an atmosphere furnace with oxygen, and carried out two-stage sintering under the condition of oxygen, among which, the first-stage sintering was fired at 620°C for 5 hours, and then the temperature was raised to 730°C for second-stage sintering, and the second-stage sintering Sintering and roasting for 30 hours; the roasted material after the two-stage sintering is cooled and crushed, and the...

Embodiment 3

[0034] a kind of like figure 1 The preparation method of the shown lithium ion battery cathode material nickel-cobalt-aluminum of the present invention may further comprise the steps:

[0035] (1) Step (1) of this embodiment is the same as step (1) of Embodiment 1;

[0036] (2) Preparation of nickel-cobalt-aluminum cathode material: mix the lithium ion battery cathode material precursor prepared in the above step (1) with a mixed lithium source of lithium hydroxide and lithium carbonate (the moles of lithium hydroxide and lithium carbonate ratio of 3:7), the molar ratio of the precursor of the lithium-ion battery positive electrode material to the mixed lithium source is 1:1.05, after mixing evenly, place it in an atmosphere furnace with oxygen, and carry out two-stage sintering under the condition of oxygen, among which The first-stage sintering is performed at 620°C for 5 hours, then the temperature is raised to 730°C for second-stage sintering, and the second-stage sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com