Heat-conducting aluminum alloy and application thereof

A technology of aluminum alloys and alloying elements, applied in the field of aluminum alloys, can solve problems such as difficulty in meeting the needs of high strength and high thermal conductivity of electronic and electrical products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

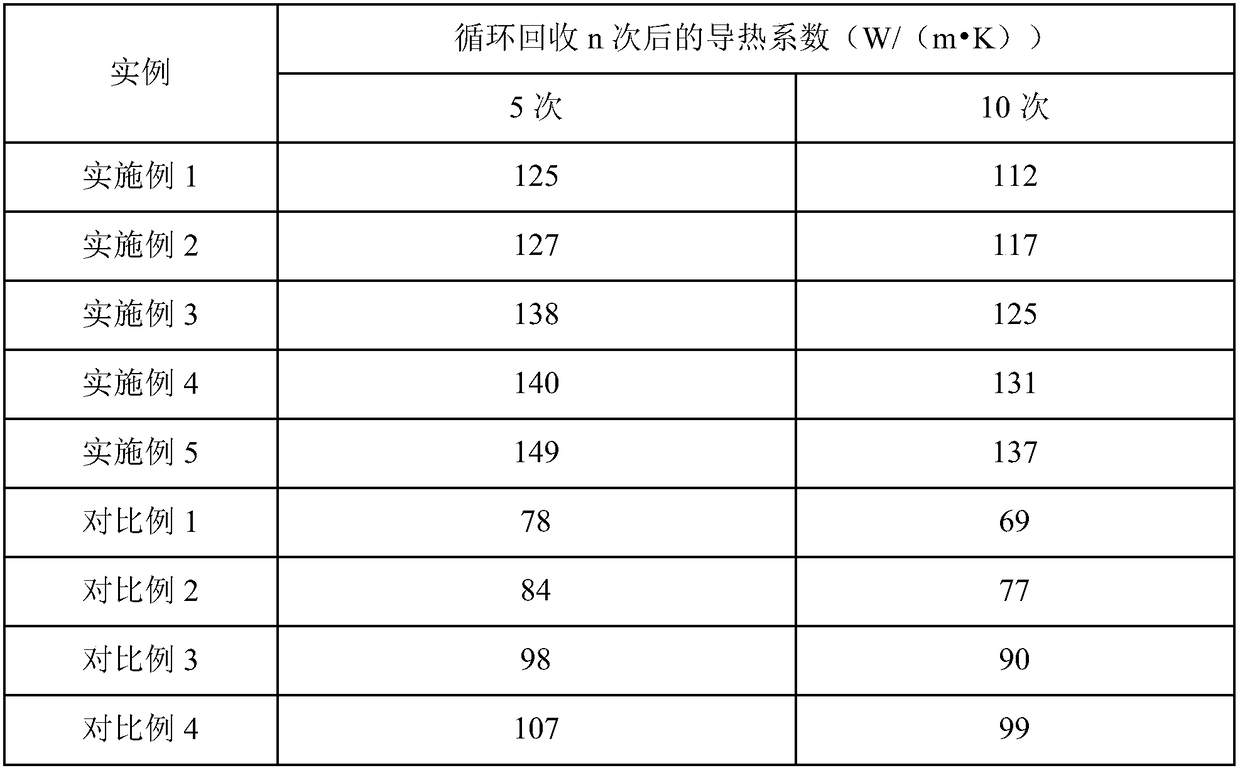

Examples

Embodiment 1

[0024] In this embodiment, based on 100 parts by weight of the total weight of the thermally conductive aluminum alloy, it contains 5.0 parts by weight of Si, 1.0 parts by weight of Fe, 0.2 parts by weight of Mg, 0.05 parts by weight of Zn, 0.05 parts by weight of Mn, and 0.05 parts by weight parts of Sr, 0.05 parts by weight of Cu and the balance of Al.

[0025] Firstly, preheat the furnace at 400°C for 25 minutes, and purge it with argon, add the corresponding weight of pure aluminum ingots for melting, when the temperature of the pure aluminum liquid reaches 800°C, let it stand at constant temperature for 25 minutes to fully melt the pure aluminum ingots ;Reduce the temperature of the furnace to 760°C, add 5.0 parts by weight of pure silicon, let it stand at constant temperature for 25 minutes, and continue to stir for 15 minutes after it melts; when the temperature of the furnace is lowered to 700°C, add the remaining master alloy, and let it stand after melting completely ...

Embodiment 2

[0027] In this embodiment, based on 100 parts by weight of the total weight of the thermally conductive aluminum alloy, it contains 11.0 parts by weight of Si, 0.4 parts by weight of Fe, 1.0 parts by weight of Mg, 0.05 parts by weight of Zn, 0.05 parts by weight of Mn, and 0.05 parts by weight parts of Sr, 0.05 parts by weight of Cu and the balance of Al.

[0028] Firstly, preheat the furnace at 400°C for 25 minutes, and purge it with argon, add the corresponding weight of pure aluminum ingots for melting, when the temperature of the pure aluminum liquid reaches 800°C, let it stand at constant temperature for 25 minutes to fully melt the pure aluminum ingots ;Reduce the temperature of the furnace to 760°C, add 11.0 parts by weight of pure silicon, let it stand at constant temperature for 25 minutes, and continue to stir for 15 minutes after it melts; Add 1.0 parts by weight of magnesium at last, after melting completely, continue stirring for 8 minutes, remove scum, add refini...

Embodiment 3

[0030] In this embodiment, based on the total weight of the thermally conductive aluminum alloy as 100 parts by weight, it contains 8.0 parts by weight of Si, 0.4 parts by weight of Fe, 0.4 parts by weight of Mg, 0.008 parts by weight of Zn, 0.008 parts by weight of Mn, and 0.05 parts by weight parts of Sr, 0.008 parts by weight of Cu and the balance of Al.

[0031]Firstly, preheat the furnace at 400°C for 25 minutes, and purge it with argon, add the corresponding weight of pure aluminum ingots for melting, when the temperature of the pure aluminum liquid reaches 800°C, let it stand at constant temperature for 25 minutes to fully melt the pure aluminum ingots ;Reduce the temperature of the furnace to 760°C, add 8.0 parts by weight of pure silicon, let it stand at constant temperature for 25 minutes, and continue to stir for 15 minutes after it melts; when the temperature of the furnace is lowered to 700°C, add the remaining master alloy, and let it stand after melting completel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com