Negative electrode material, electrochemical device comprising negative electrode material and electronic device

A negative electrode material, coating technology, applied in electrochemical generators, nanotechnology for materials and surface science, negative electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

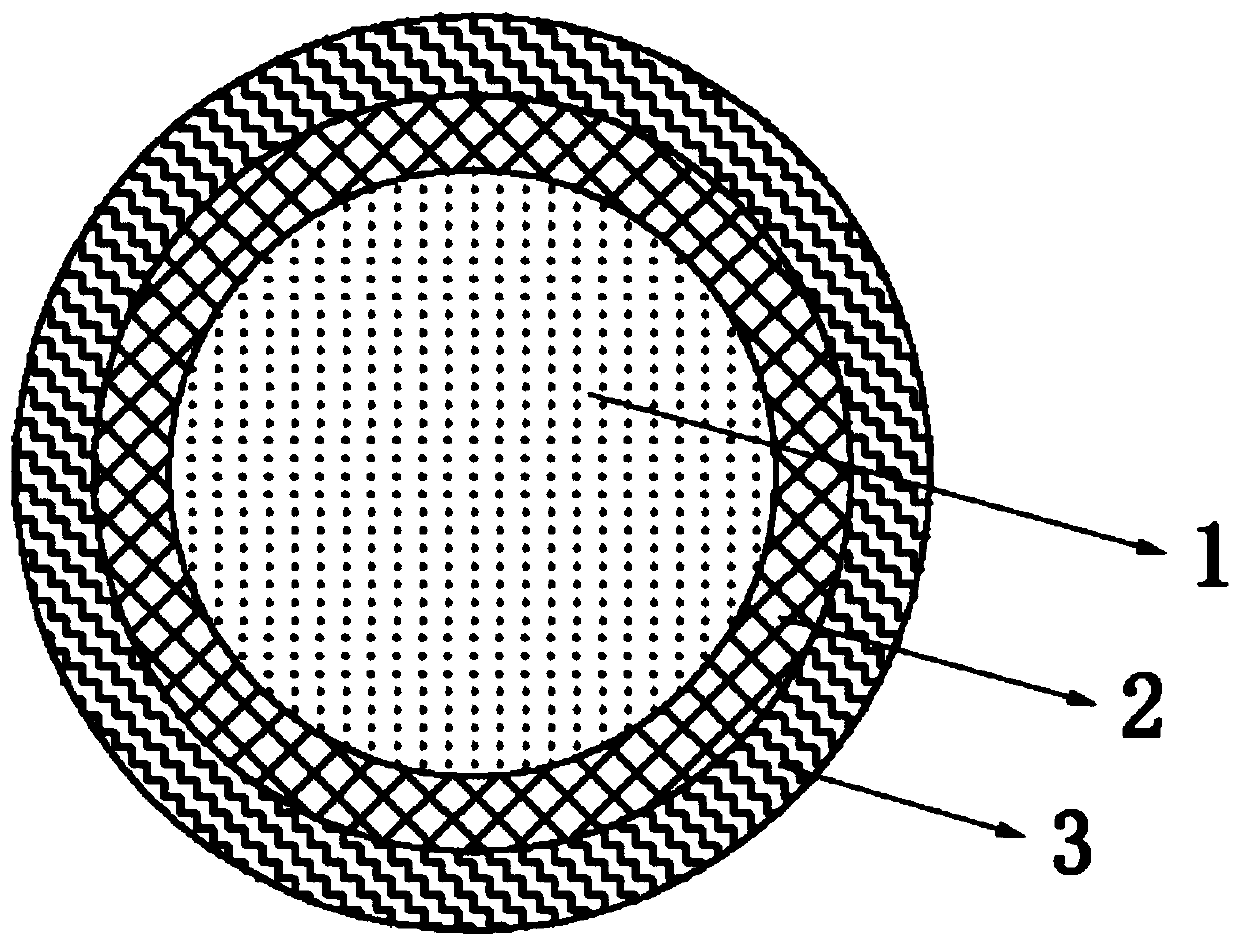

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] 2. Preparation method of negative electrode material

[0036]The embodiment of the present application provides a method for preparing any of the above negative electrode materials, the method comprising:

[0037] (1) Adding the pre-lithiated silicon-oxygen material and the inorganic coating material to a solvent to form a suspension, filtering and drying to obtain a pre-lithiated silicon-oxygen material whose surface is coated with an inorganic coating layer; and

[0038] (2) Add the above-mentioned pre-lithiated silicon oxide material and polymer whose surface is coated with an inorganic coating layer into a solvent to form a mixed solution, remove the solvent, and heat at about 50-300°C for about 4-12 hours to obtain Negative material.

[0039] In some embodiments, the inorganic coating material includes at least one of the following materials: phosphoric acid, tripolyphosphoric acid, sodium tripolyphosphate, potassium tripolyphosphate, sodium metaaluminate, potassi...

Embodiment

[0090] The performance evaluation of the examples and comparative examples of the lithium-ion battery according to the present application will be described below.

[0091] 1. Preparation of negative electrode active materials

[0092] Prepare the negative electrode active material of embodiment 1-18 according to the following method:

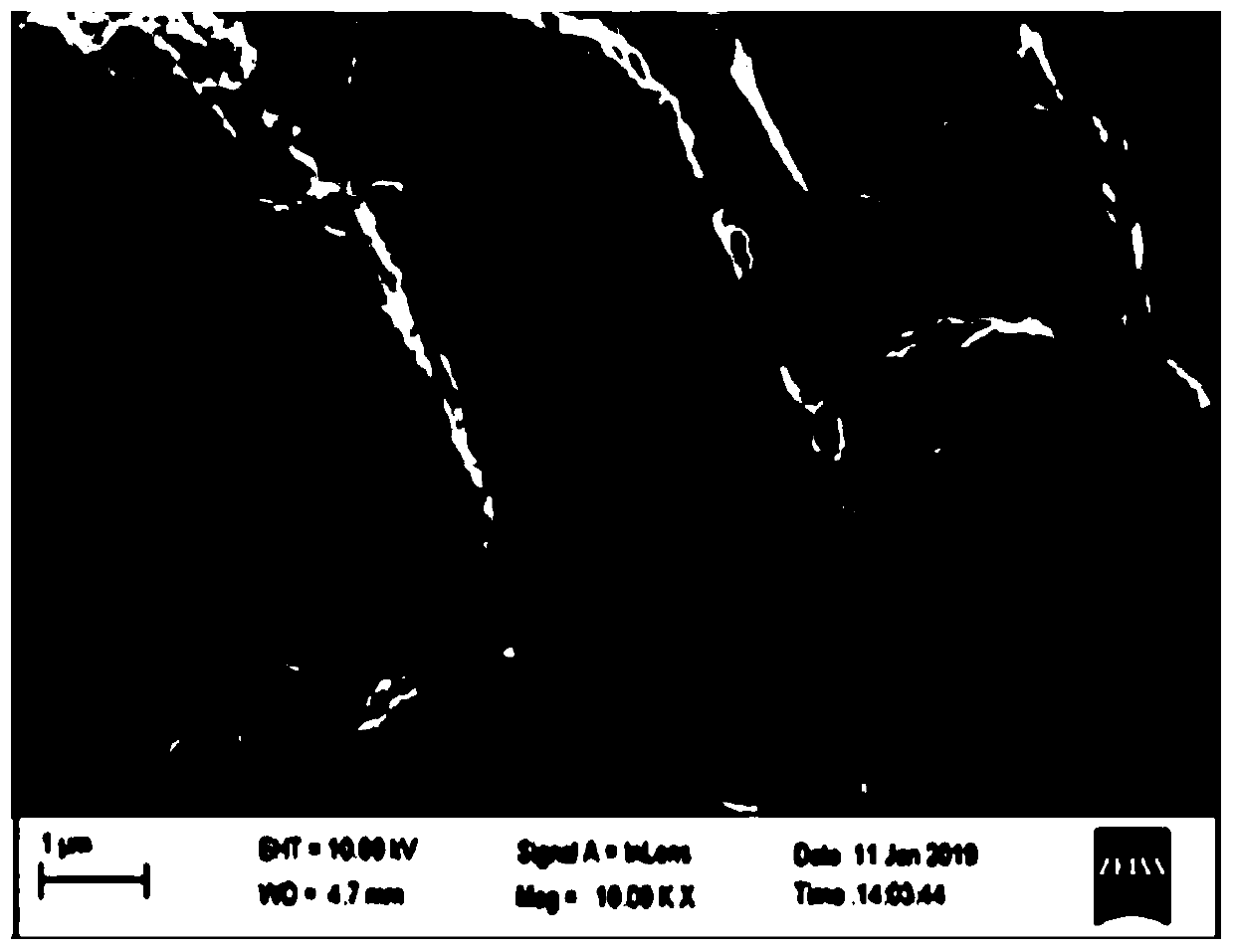

[0093] (1) Pre-lithiated silicon-oxygen material (C%=about 3.2%, Dv50=about 5.1 μm, silicon grain size is about 5nm, buffer phase is Li 2 SiO 3 ) and the inorganic coating material are added to ethanol, stirred for about 0.5-4 hours until a uniform suspension is formed, the formed suspension is filtered, and the filtered material is dried at about 80°C for about 12 hours to obtain an inorganic coating on the surface Layer-coated pre-lithiated silicon oxide material;

[0094] (2) Add the above-mentioned pre-lithiated silicon-oxygen material and the polymer whose surface is covered by the inorganic coating layer to ethanol to form a suspension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com