High-strength porous ceramics and low-temperature preparation method thereof

A porous ceramic, high-strength technology, applied in the field of porous ceramics, can solve the problems of low mechanical strength and high sintering temperature, and achieve the effects of excellent mechanical properties, high mechanical strength and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

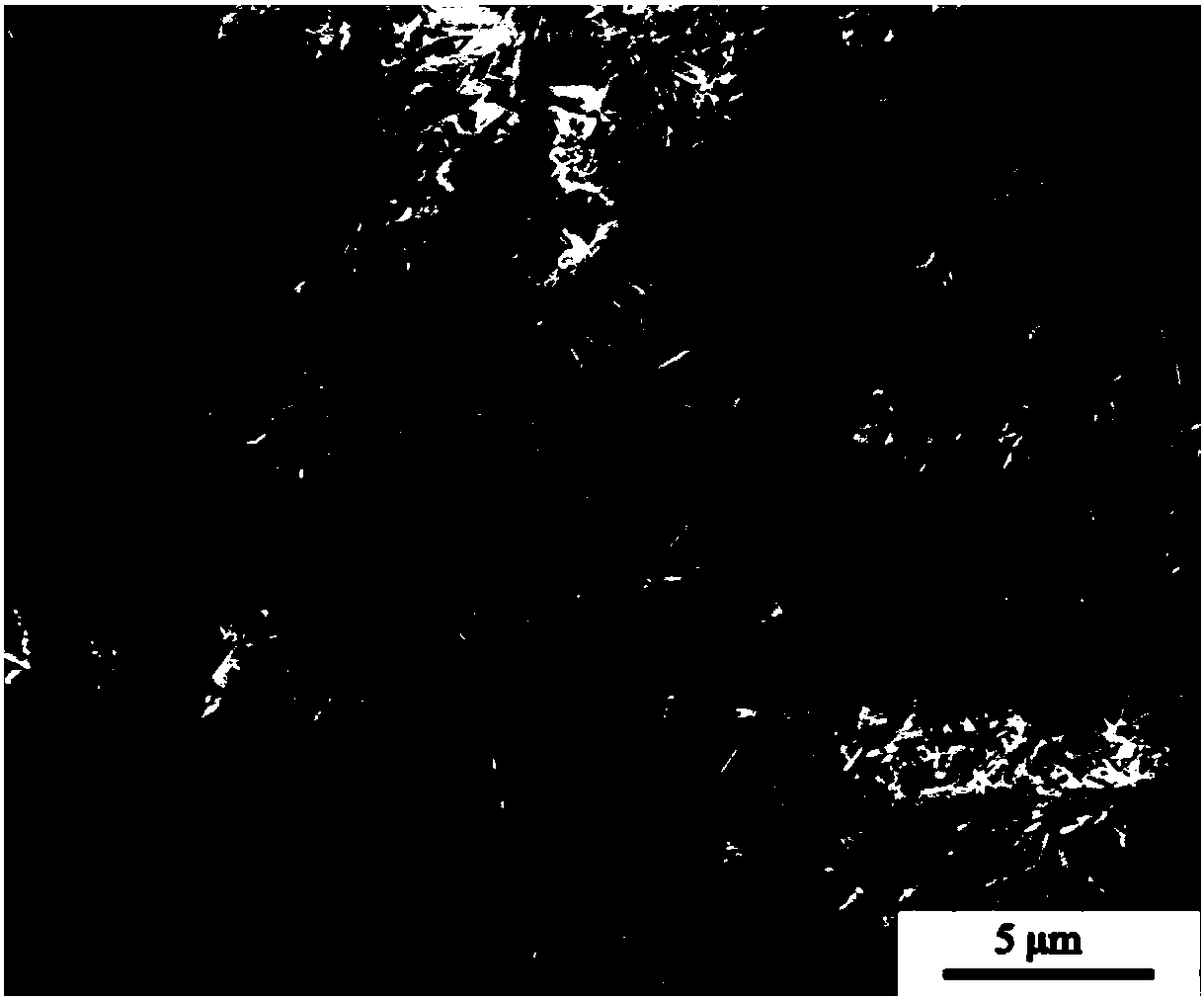

Image

Examples

Embodiment 1

[0035] A preparation method of high-strength porous ceramics, comprising the following steps: the percentages in the examples are mass percentages;

[0036] (1) Construction waste (mainly composed of SiO 2 : 23.5%, Al 2 o 3 : 35.0%, Fe 2 o 3 : 6.5%, CaO: 21.7%, MgO: 3.7%, Na 2 O: 2.1%, K 2 O: 2.9%, etc.) 55.2%, low-grade aluminum ore (the main component is Al 2 o 3 : 62.3%, SiO 2 : 9.1%, Fe 2 o 3 : 13.5%, TiO 2 : 4.5%, K 2 O: 6.9%, etc.) 34.8%, Na 2 CO 3 6.0%, Borax 2.0%, K 3 PO 4 2.0%, proportioned ingredients, with a ball mill at a speed of 400r / min, ball milling and mixing for 12 hours to obtain mixed raw materials;

[0037] (2) Compress the mixed raw materials under 100 MPa, dry (40° C.) to obtain a green body; the mixed raw materials can be granulated first, and then pressed to form;

[0038] (3) Put the body into a high-temperature furnace, heat up to 1050°C at a heating rate of 35°C / min for firing, and hold for 200 minutes to obtain a high-strength po...

Embodiment 2

[0041] A preparation method of high-strength porous ceramics, comprising the following steps: the percentages in the examples are mass percentages;

[0042] (1) Coal gangue (mainly composed of SiO 2 : 51.0%, Al 2 o 3 : 39.0%, Fe 2 o 3 : 2.2%, CaO: 0.9%, TiO 2 : 2.7%, K 2 O: 1.9%, Na 2 O: 0.8%, MgO: 1.3%) 33.0%, ceramic waste slag (mainly composed of SiO 2 : 48.7%, Al 2 o 3 : 32.0%, Fe 2 o 3 : 2.4%, TiO 2 : 1.5%, K 2 O: 3.4%, Na 2 O: 2.8%, MgO: 8.6%) 21.0%, low-grade clay ore (mainly composed of SiO 2 : 48.7%, Al 2 o 3 : 34.7%, Fe 2 o 3 : 2.5%, Na 2 O: 3.5%, TiO 2 : 2.5%, K 2 O: 3.8%) 10.2%, low-grade potassium feldspar (mainly composed of SiO 2 : 63.0%, Al 2 o 3 : 16.7%, K 2 O: 4.7%, Fe 2 o 3 : 4.5%, Na 2 O: 3.5%, etc.) 13.8%, KNO 3 12.0%, Phosphate (NaH 2 PO 4 and K 3 PO 4 , content is respectively 7.0%, 3.0%) 10.0%, proportioned ingredients, with ball mill with 700r / min rotating speed, ball mill mixing 4h, obtains the raw material of mixing;...

Embodiment 3

[0047] A preparation method of high-strength porous ceramics, comprising the following steps: the percentages in the examples are mass percentages;

[0048] (1) Low-grade clay ore (mainly composed of SiO 2 : 47.3%, Al 2 o 3 : 26.8%, Fe 2 o 3 : 2.8%, Na 2 O: 3.5%) 37.8%, low-grade bauxite (the main component is Al 2 o 3 : 62.9%, SiO 2 : 10.4%, Fe 2 o 3 : 11.8%, TiO 2 : 4.5%, K 2 O: 5.2%) 30.0%, low-grade mica ore (mainly composed of SiO 2 : 68.0%, Al 2 o 3 : 20.3%, Fe 2 o 3 : 1.9%, K 2 O: 4.7%) 12.2%, Na 2 HPO 4 8.0%, Sulfate (CaSO 4 and MgSO 4 , the contents were 6.0% and 2.0% respectively) 8.0%, MgCO 3 4.0%, proportioned ingredients, using a ball mill with a rotating speed of 800r / min, ball milling and mixing for 0.5h, to obtain mixed raw materials;

[0049] (2) Compress the mixed raw materials at 200MPa, dry (120°C) to obtain a green body; the mixed raw materials can be granulated first, and then pressed into shape; the mixed raw materials can first p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com