Patents

Literature

37 results about "Chromium Hexavalent Compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A highly corrosive, inorganic substance that contains the metallic element chromium in its positive-6 valence state. Chromium hexavalent compounds are used in stainless steel production, in chrome plating, in the manufacture of dyes and pigments, in leather tanning, in wood preservation and are used as corrosion inhibitors. Inhalation exposure of these compounds mainly affects the respiratory tract causing shortness of breath, nasal itching, asthma, coughing, bronchitis and pneumonia, but can also affect the liver, kidneys, gastrointestinal tract and the immune system. Chromium hexavalent compounds are carcinogenic in humans and are associated with an increased risk of developing lung cancer and cancer of the sinonasal cavity. (NCI05)

Methods for Identification of Materials Causing Corrosion on Metallic Substrates within ZPGM Catalyst Systems

InactiveUS20150004709A1Improve catalytic performanceChemical analysis using catalysisMaterial analysis using wave/particle radiationHigh concentrationMetal catalyst

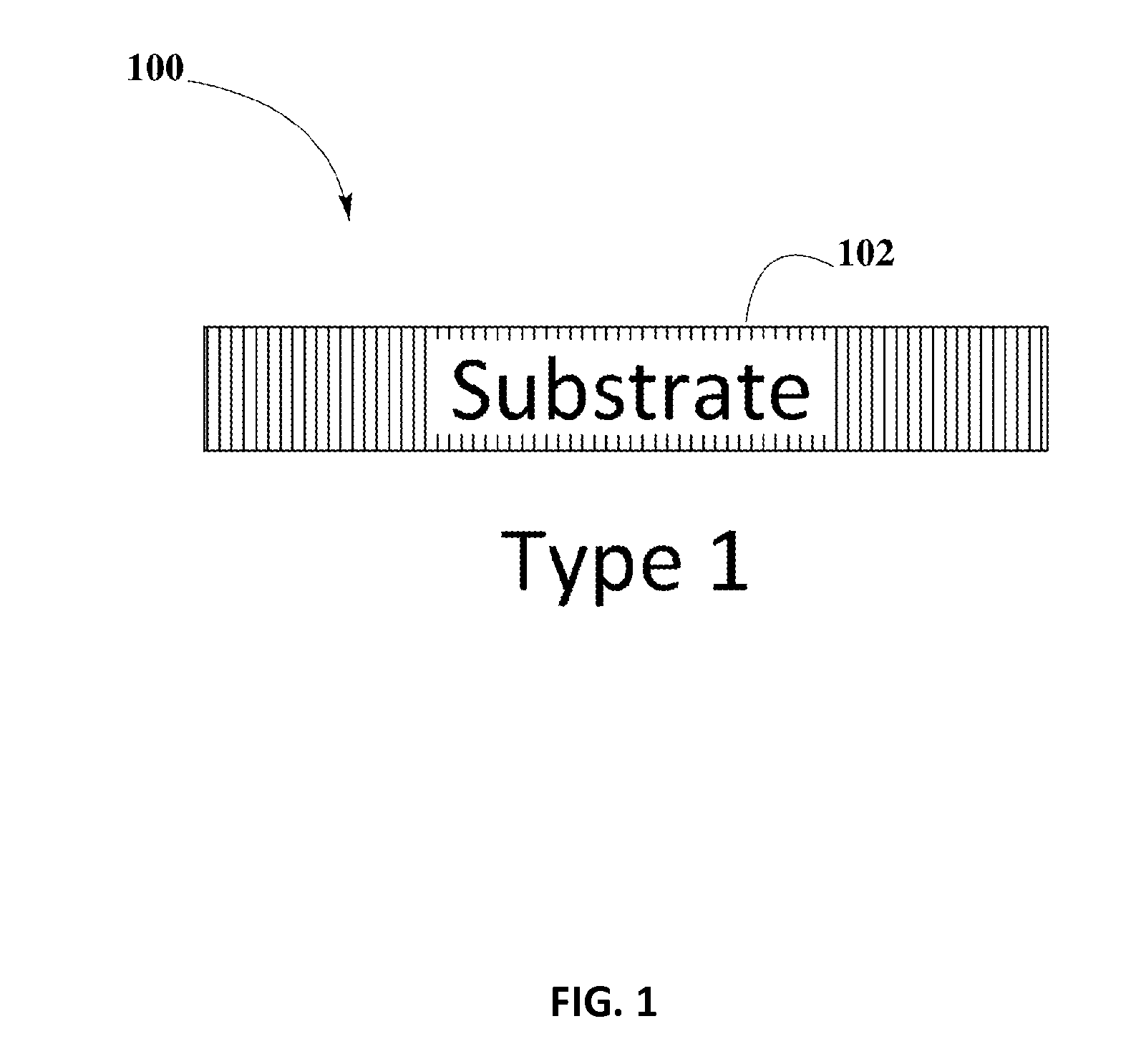

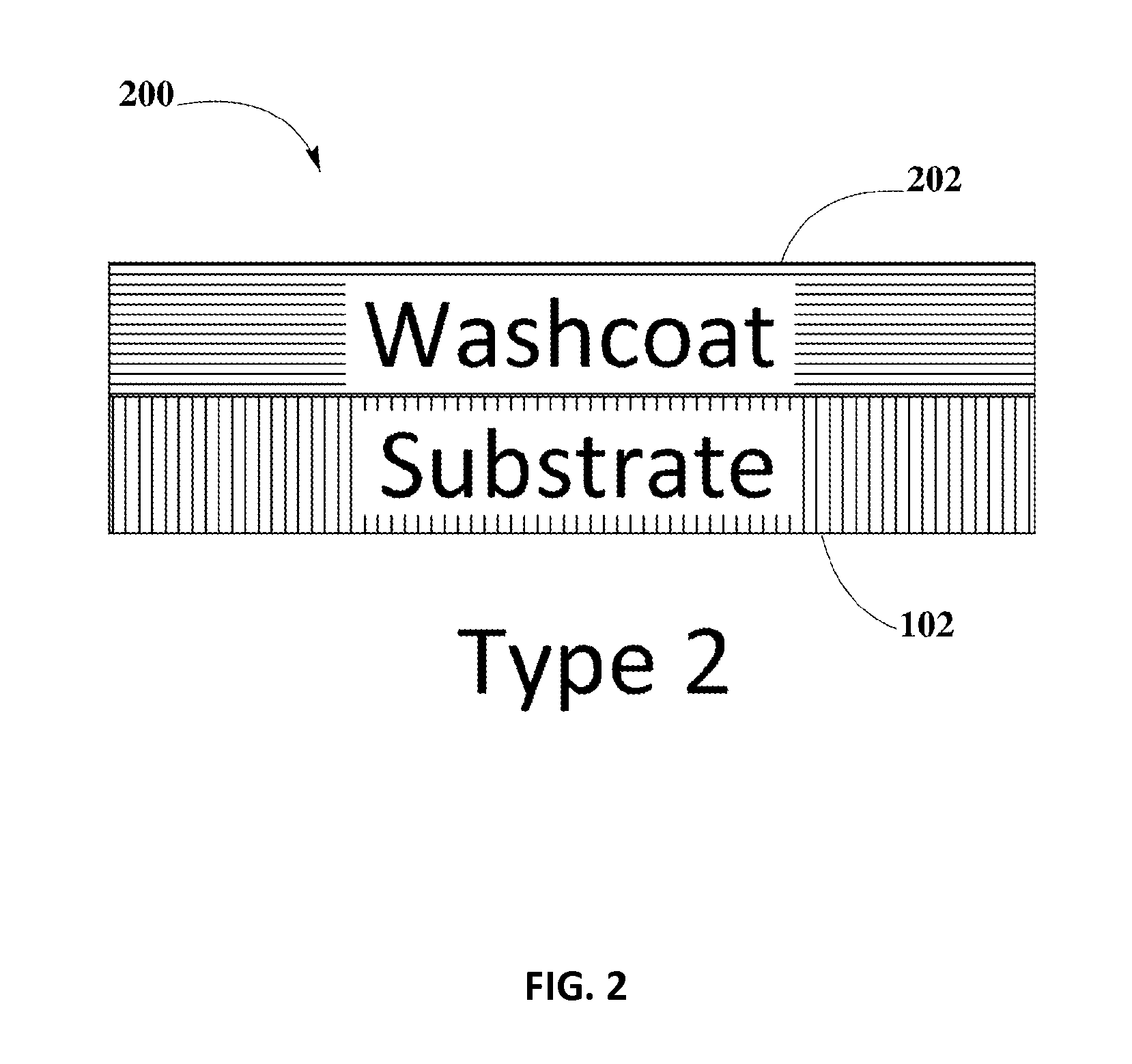

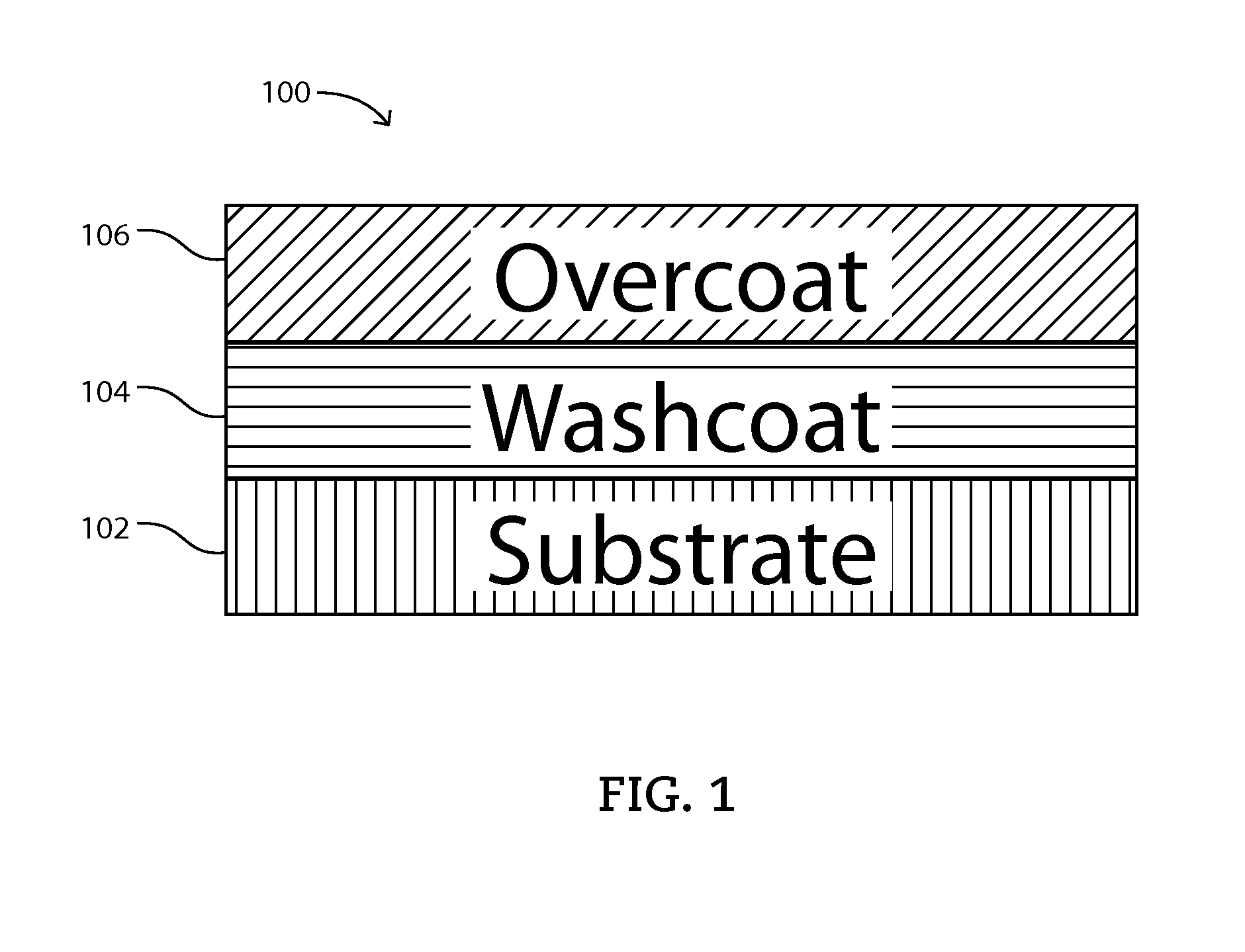

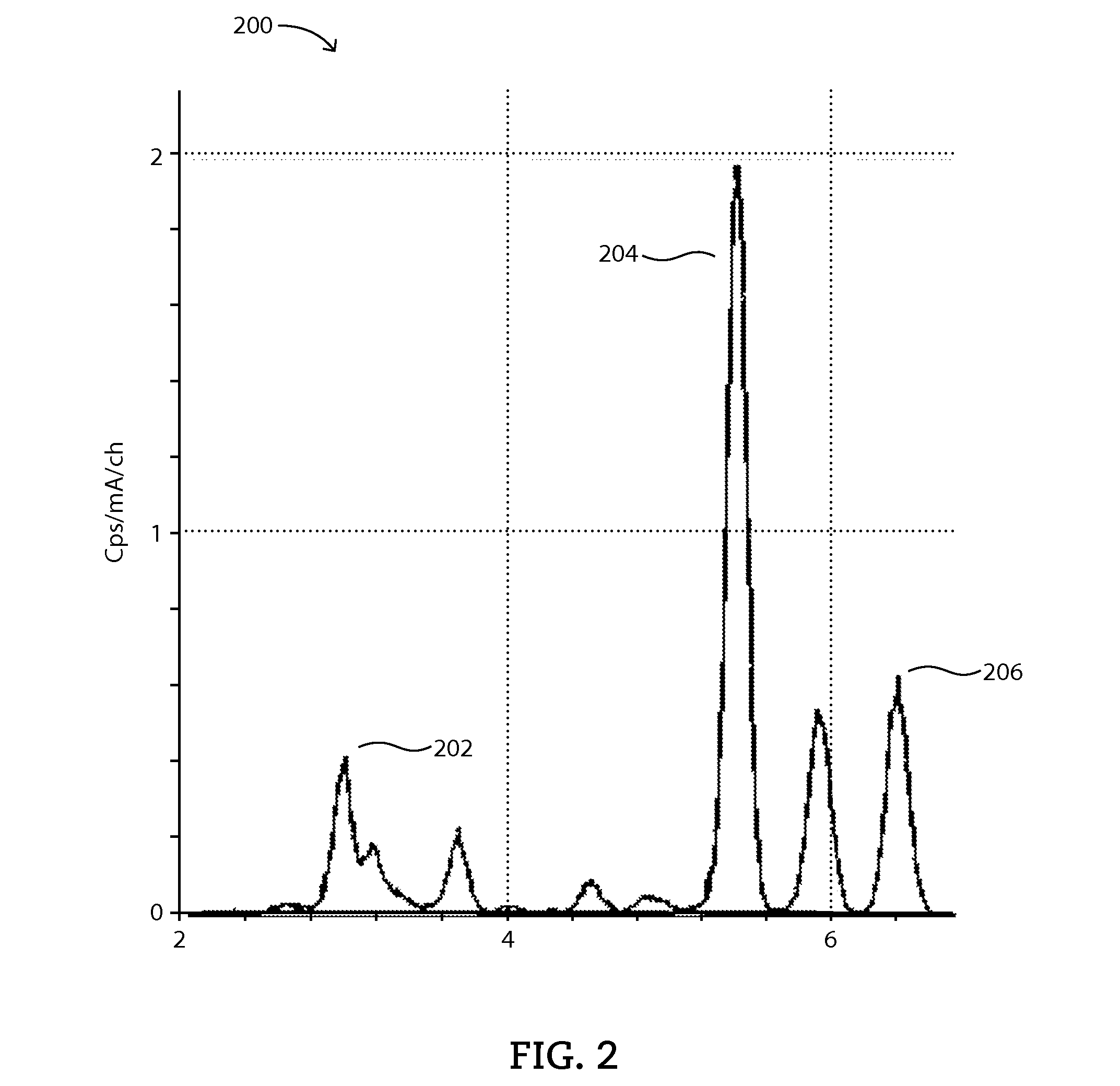

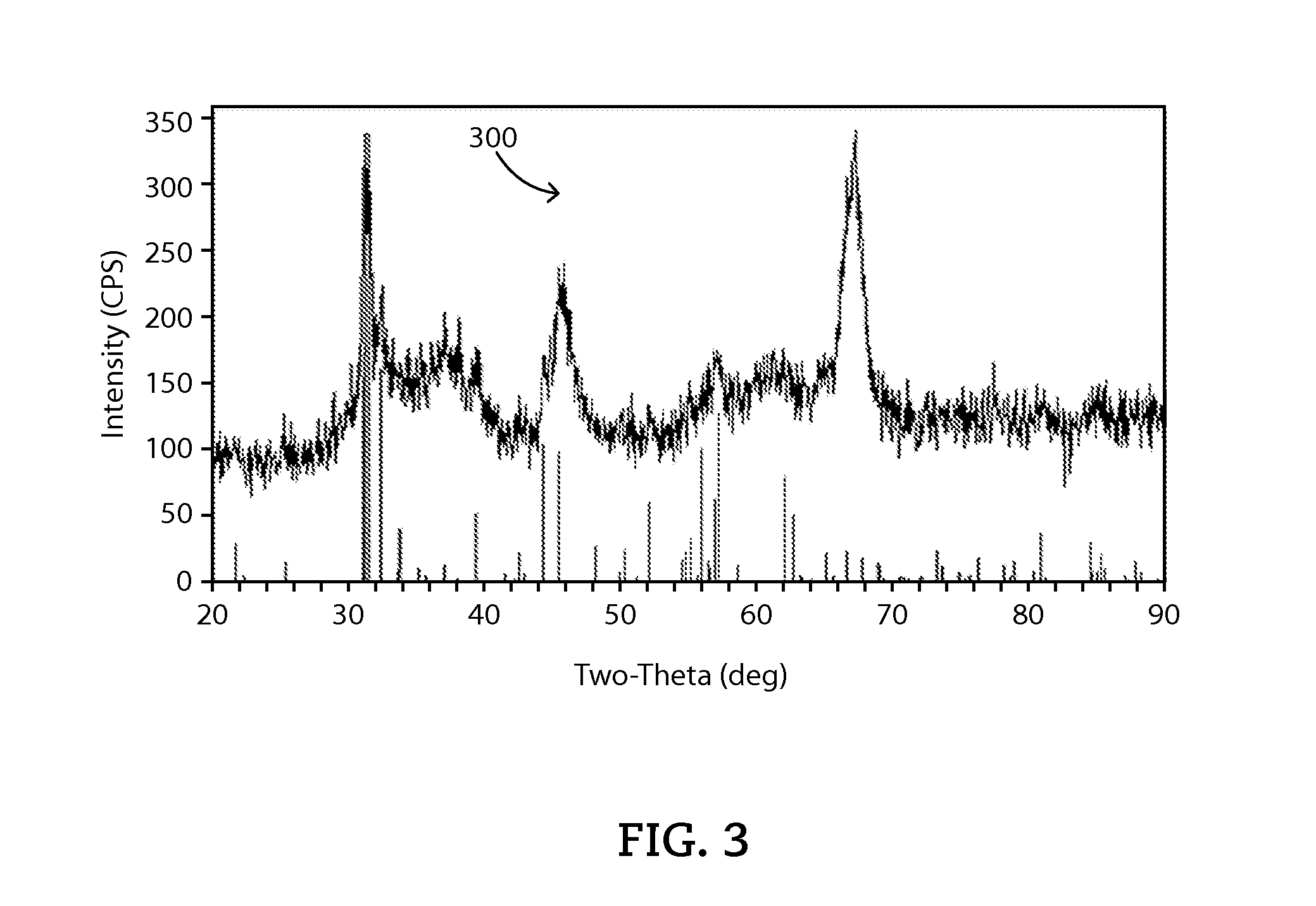

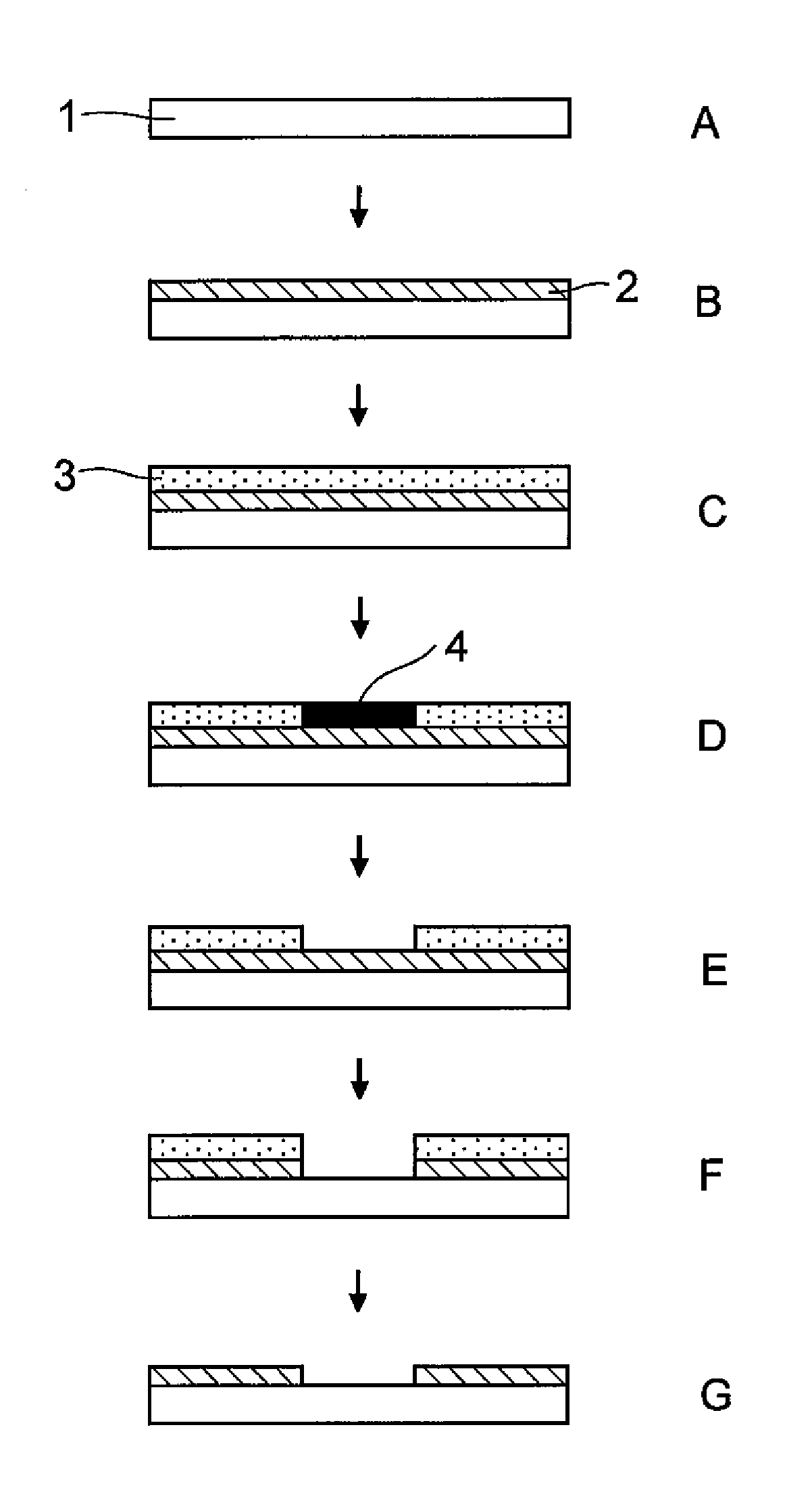

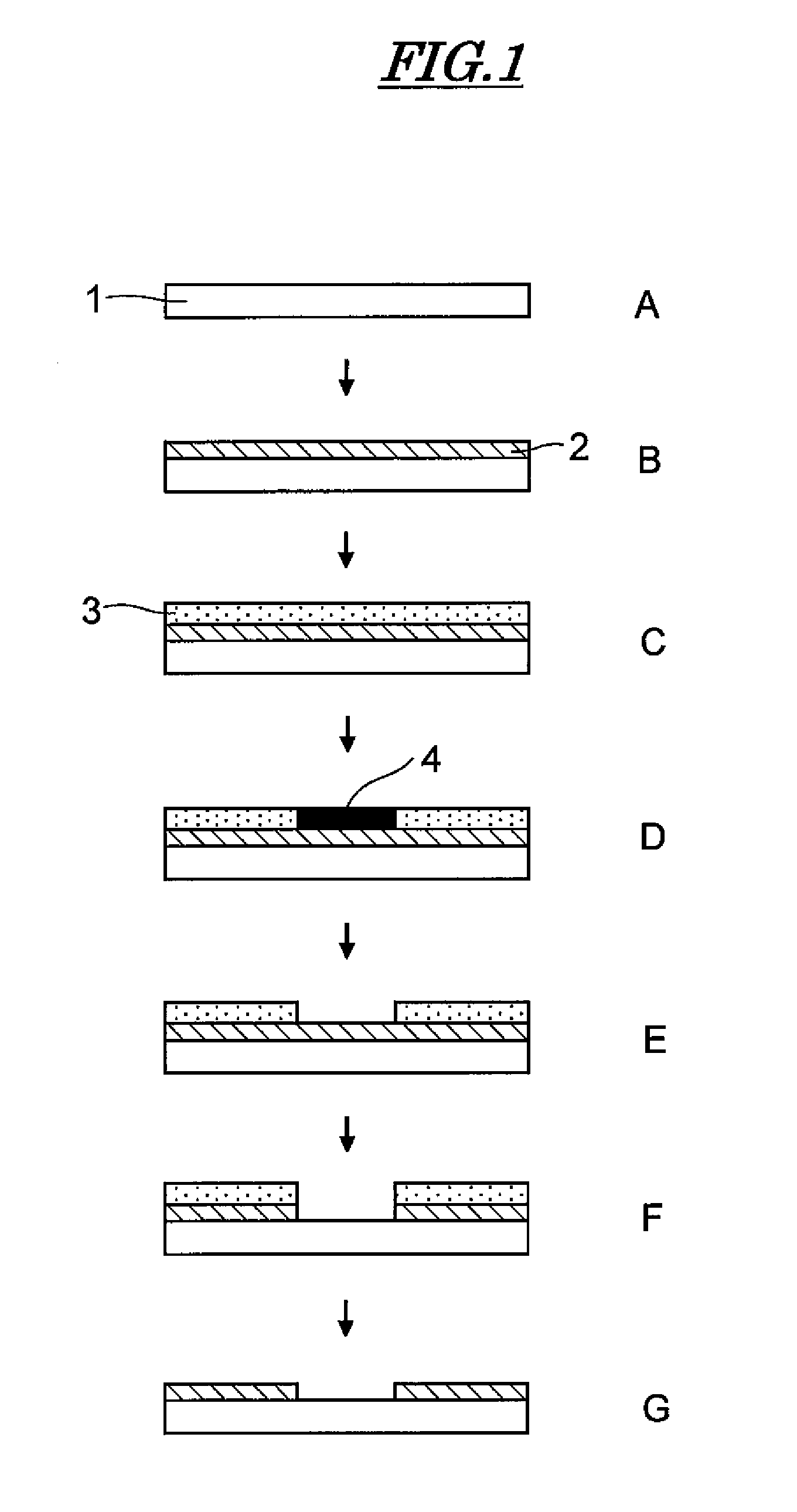

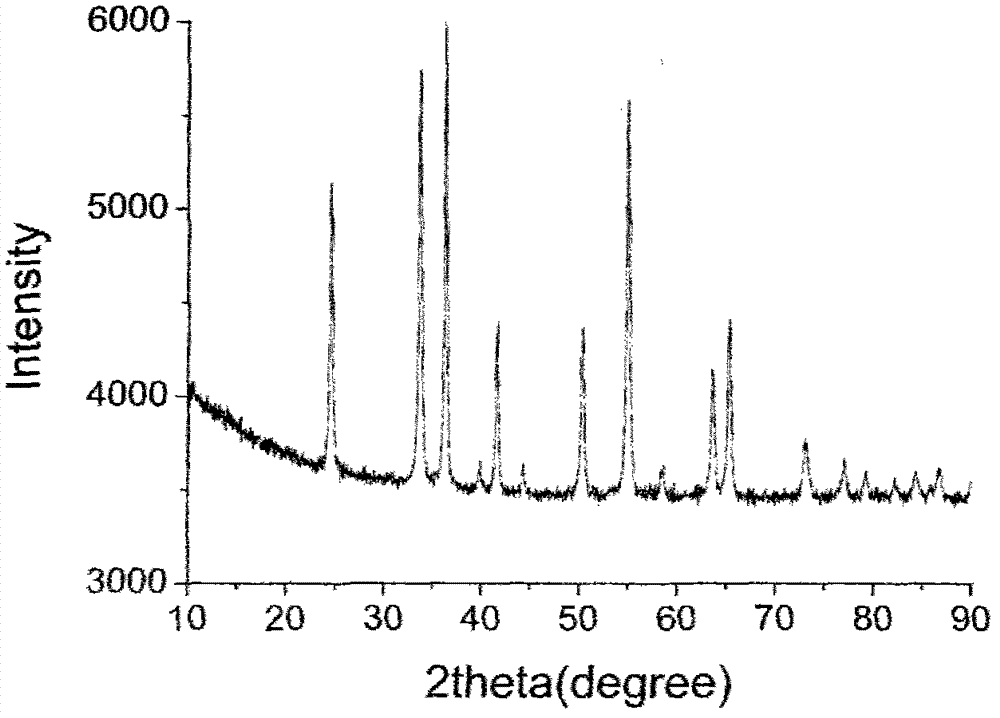

The present disclosure provides an identification process which may employ various identification techniques on Zero platinum group metal (ZPGM) catalyst systems, in order to identify responsible materials for the formation of corrosion material, such as hexavalent chromium compounds. Identification analysis, such as X-ray diffraction analysis (XRD), X-ray fluorescence (XRF), and X-ray Photoelectron Spectroscopy (XPS) may be performed on various thermally treated ZPGM catalyst systems, such as in bare substrate, substrate with one type of ZPGM in washcoat, a substrate with one type of ZPGM in overcoat and substrate combination of ZPGM metals in both washcoat and overcoat. Results of identification analysis may show that regardless of metal catalyst (for example Ag, Cu, Ce), hexavalent chromium (Cr6+) may be formed on aged catalysts systems, which may be due to the high concentration of chromium in substrate. Therefore, corrosion and production of hexavalent chromium may initiate from elements found in the substrate and not from elements within the ZPGM metal catalysts.

Owner:CLEAN DIESEL TECHNOLOGIES

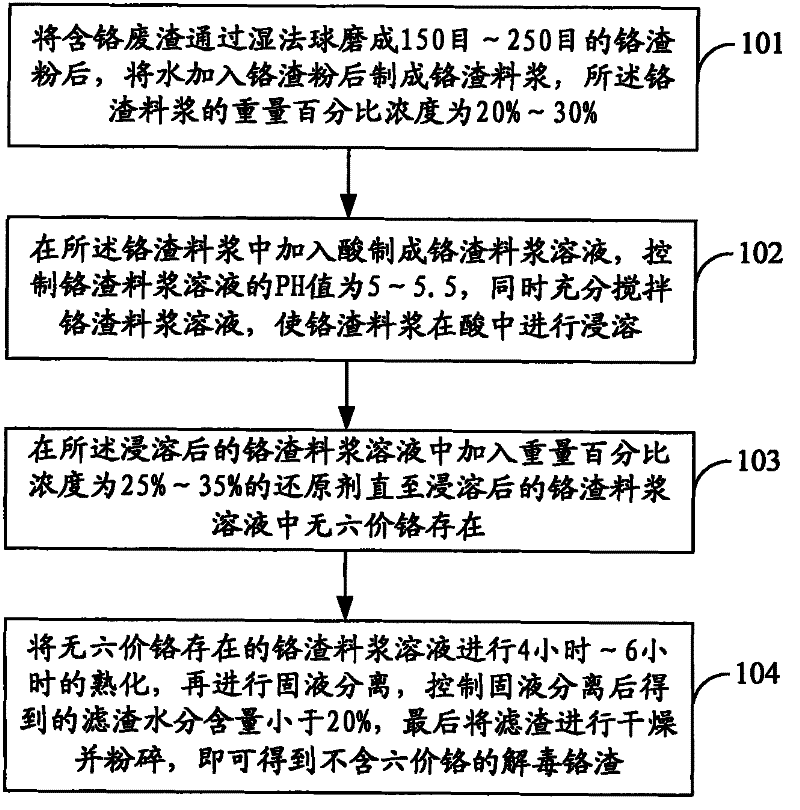

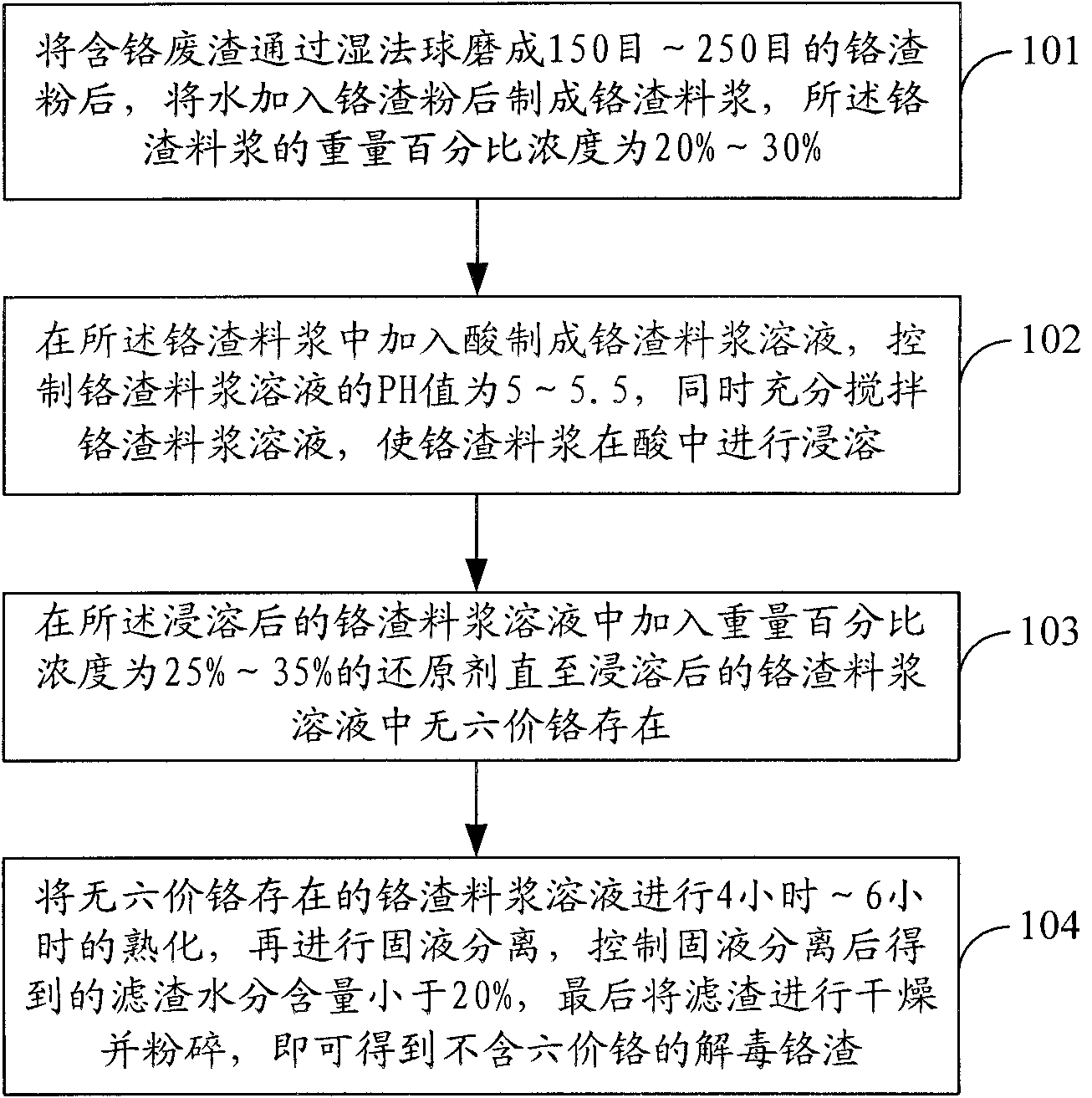

Method for detoxicating chromium residues and comprehensive utilization of detoxicated chromium residues

InactiveCN102189093ASave land resourcesSolid waste managementSolid waste disposalSlurryChromium Hexavalent Compound

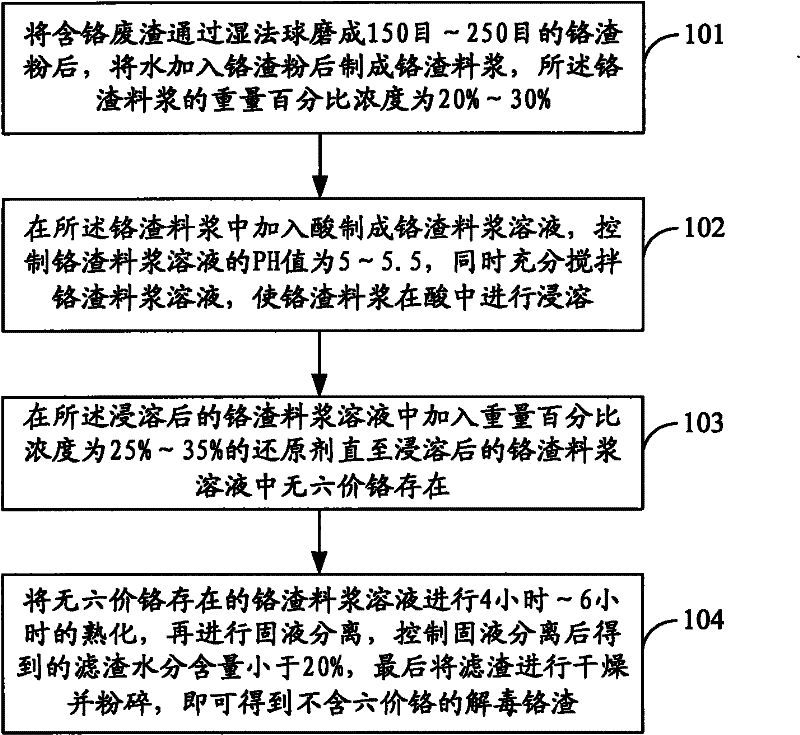

The invention relates to a method for detoxicating chromium residues and the comprehensive utilization of the detoxicated chromium residues. The method for detoxicating the chromium residues comprises the following steps of: performing wet ball milling on chromium-containing waste residues to obtain chromium residue powder; adding water into the chromium residue powder to prepare chromium residue slurry; adding acid into the chromium residue slurry to prepare chromium residue slurry solution, and fully stirring the chromium residue slurry solution simultaneously to make the chromium residue slurry immersed in the acid; adding a reducing agent into the immersed chromium residue slurry solution until hexavalent chromium does not exist in the immersed chromium residue slurry solution; curing the chromium residue slurry solution without the hexavalent chromium, and performing solid-liquid separation; and drying and grinding filter residues to obtain the detoxicated chromium residues without the hexavalent chromium. By the method for detoxicating the chromium residues, various hexavalent chromium compounds contained in the chromium residues can be systematically and completely detoxicated and removed, the hexavalent chromium in various produced building material products is comprehensively utilized, and the content of extract is less than 0.1mg / L.

Owner:刘杰

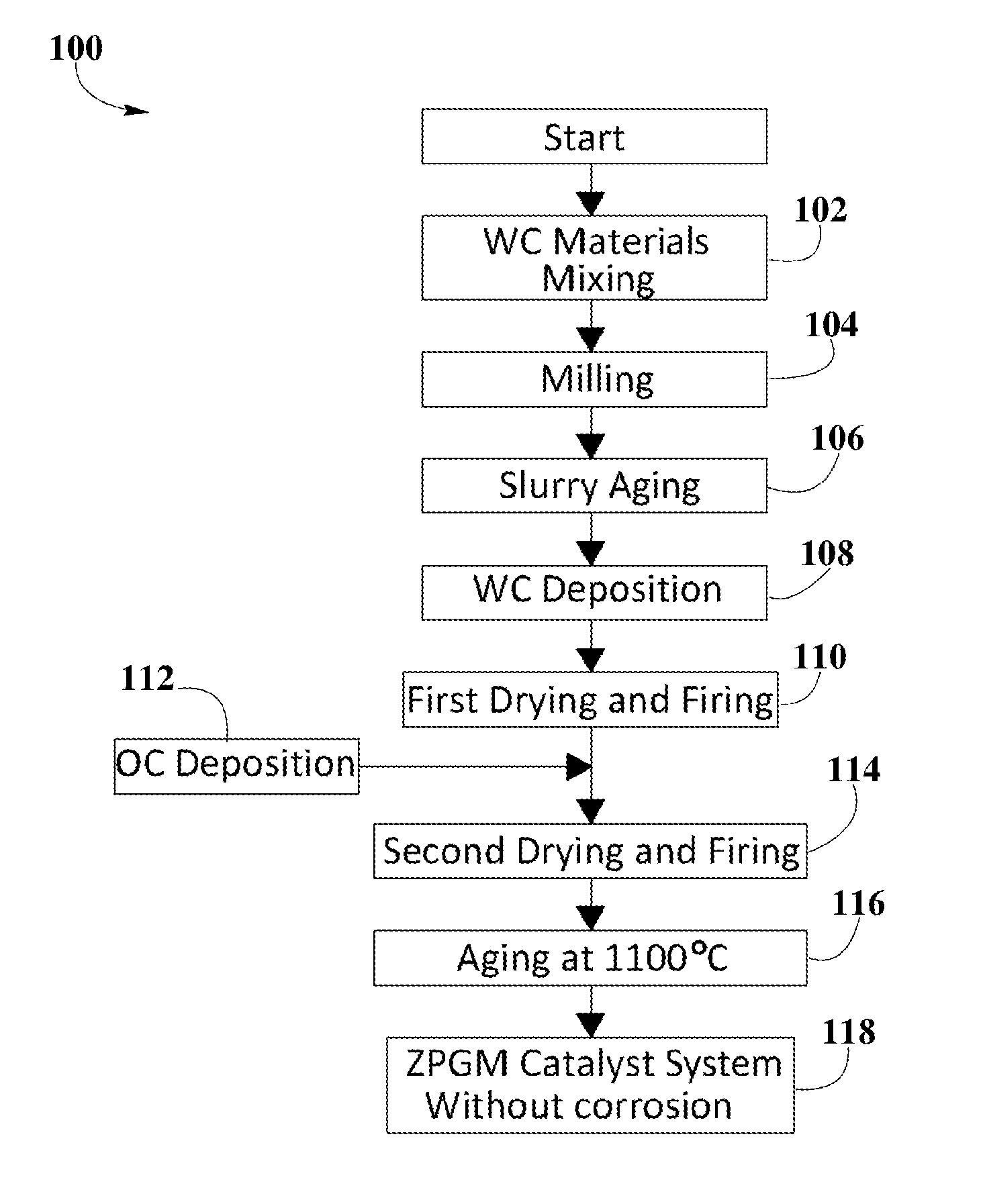

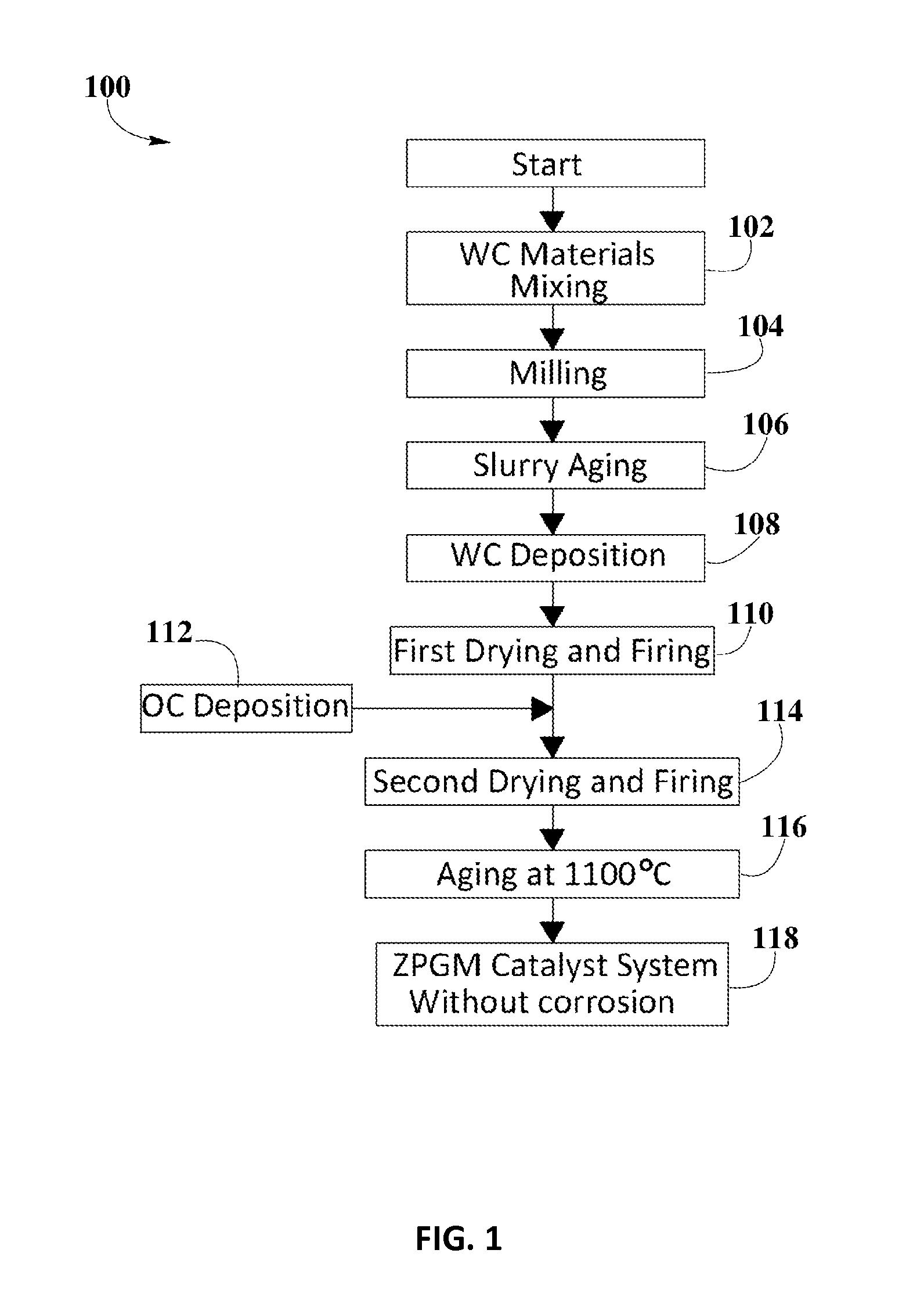

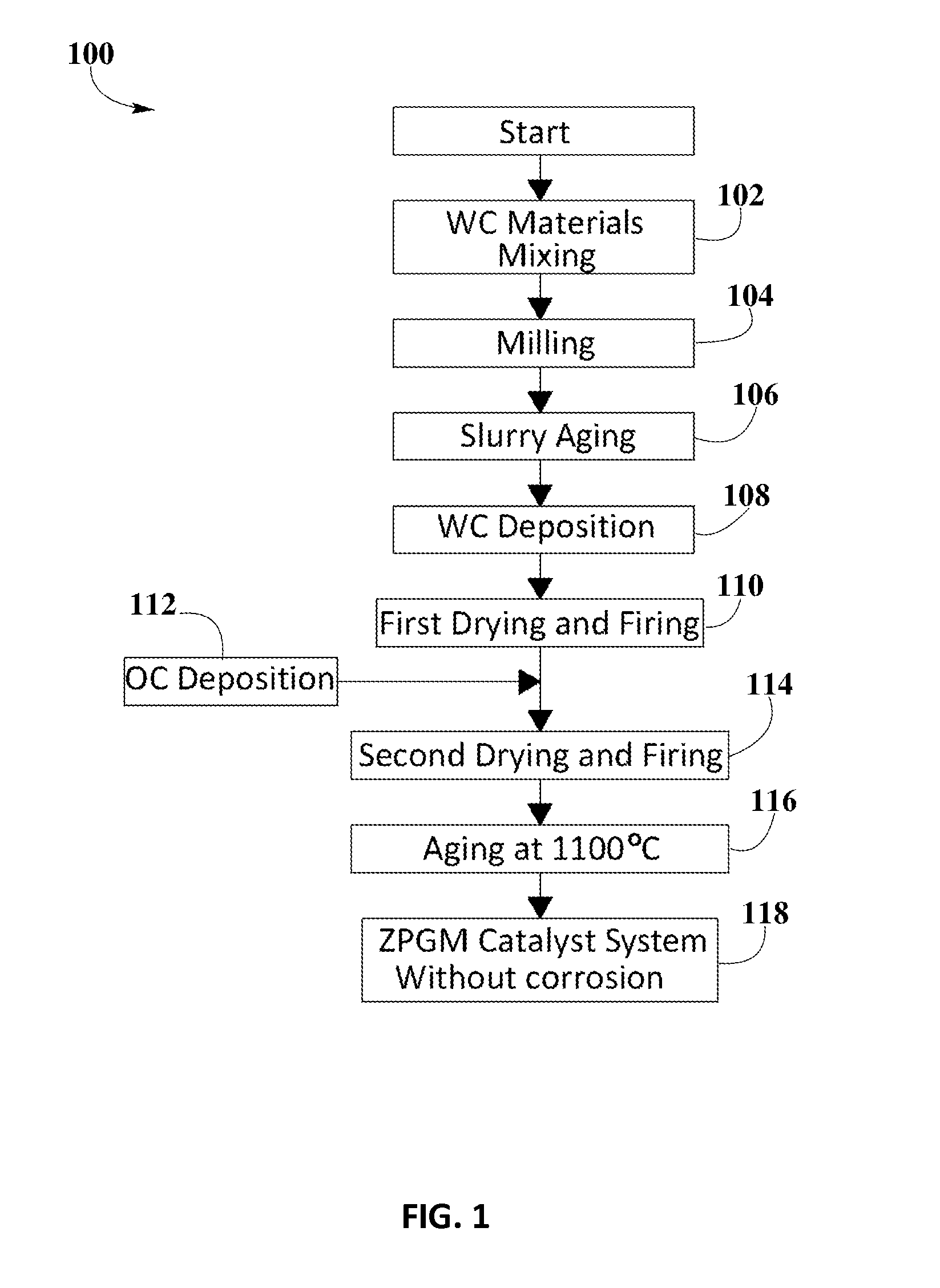

Process for elimination of hexavalent chromium compounds on metallic substrates within zero-PGM catalyst systems

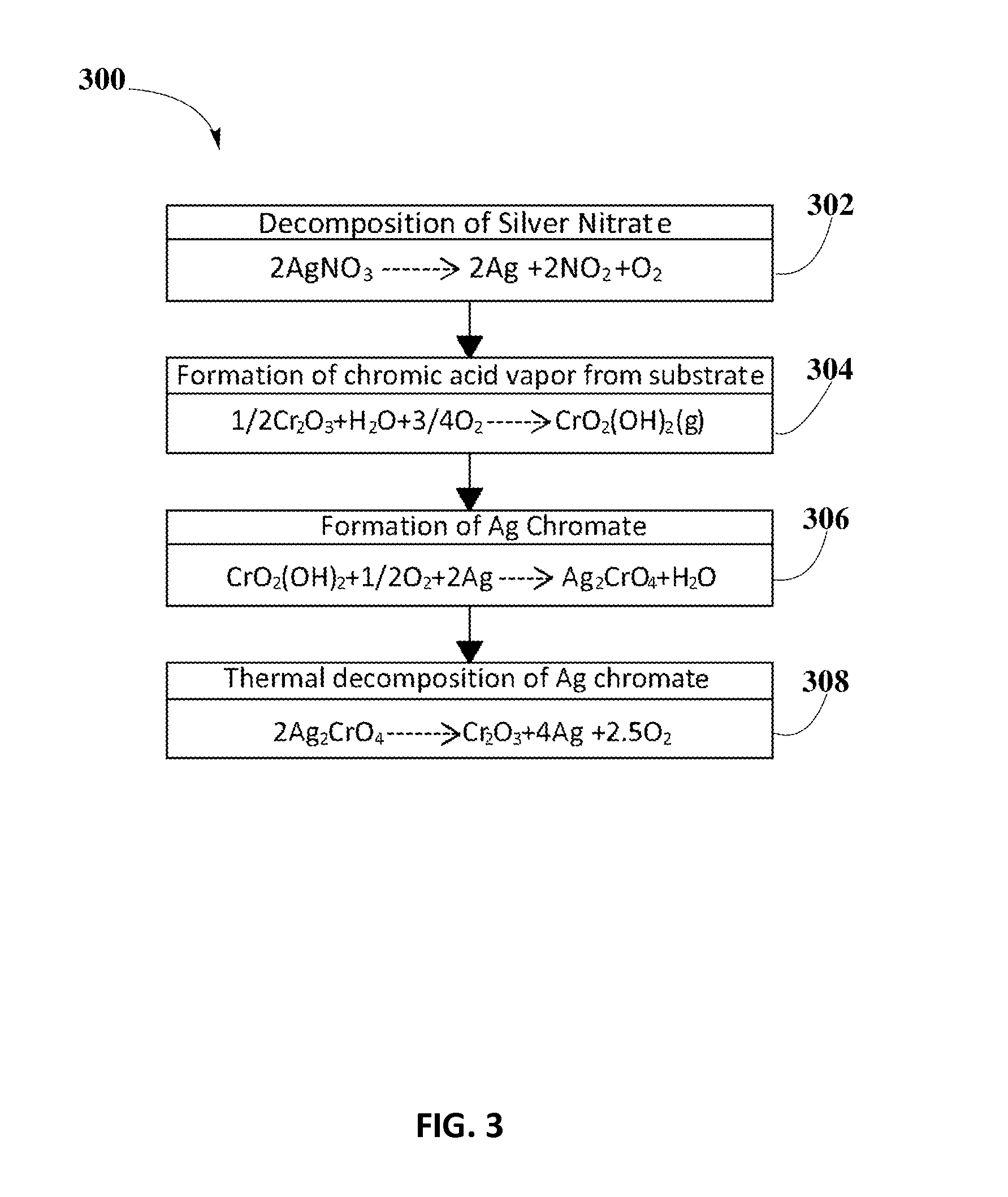

InactiveUS8969228B2Inhibition formationHigh activityInorganic chemistryCatalyst protectionChromium CompoundsDecomposition

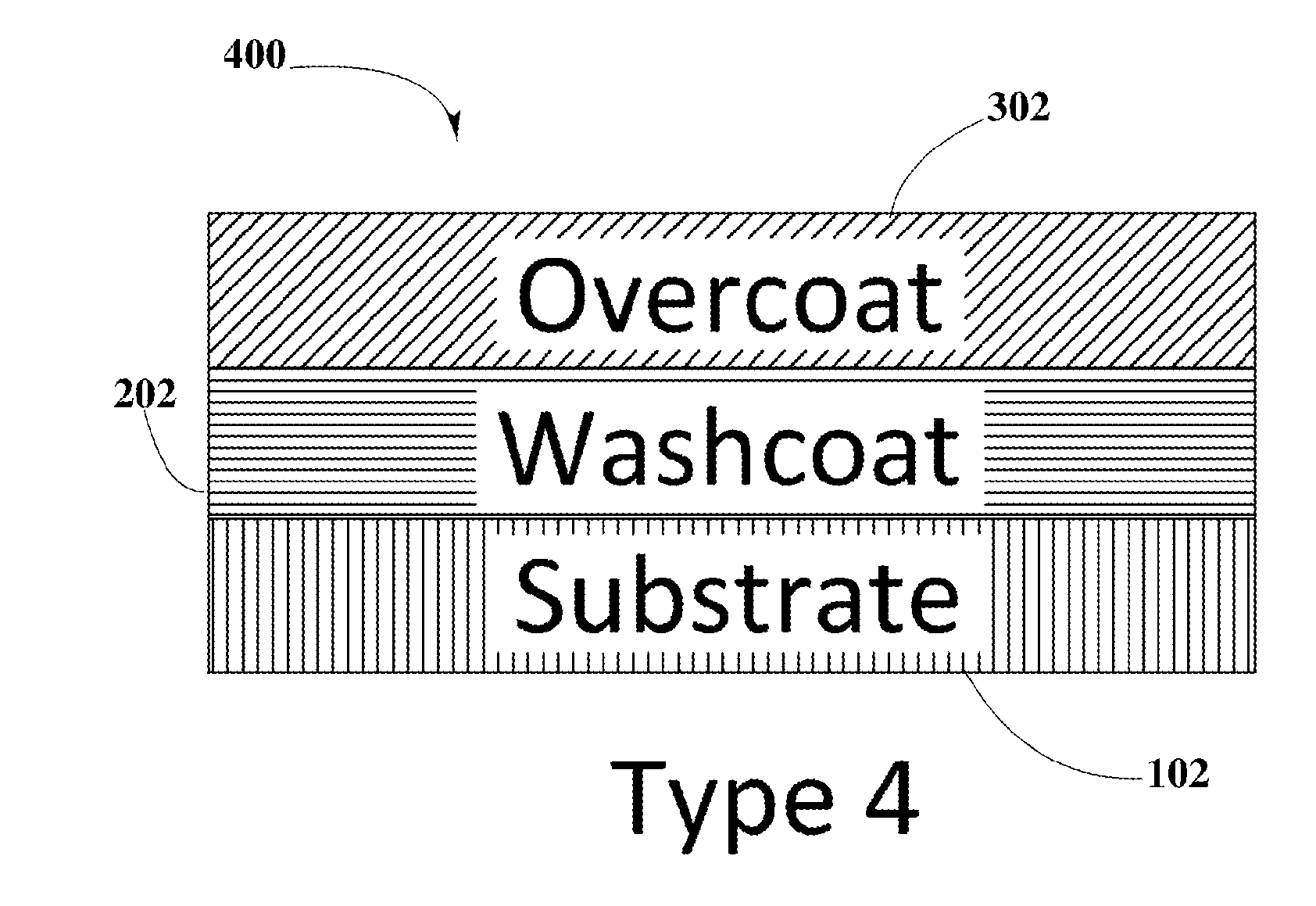

Systems and Methods for manufacturing ZPGM catalysts systems that may allow the prevention of formation or the conversion of corrosion causing compounds, such as hexavalent chromium compounds, within ZPGM catalyst systems are disclosed. ZPGM catalysts systems, may include metallic substrate, which may include alloys of iron and chromium, a washcoat and an overcoat. Disclosed manufacturing processes may include a thermal decomposition of hexavalent chromium compounds which may allow the decomposition of such compounds into trivalent chromium compounds, and may also produce metallic catalyst, such as silver.

Owner:CLEAN DIESEL TECHNOLOGIES

Aluminum elements and processes for the preparation of the same and chemical agents therefor

InactiveUS20050194574A1Not to damageImprove corrosion resistanceLiquid surface applicatorsDispersed particle filtrationTitaniumChromium Hexavalent Compound

There are provided aluminum elements covered on their surfaces with a coating film free from harmful hexavalent chromium compounds and fluorine compounds. Particularly, aluminum dicast and aluminum cast materials having excellent paint adherence and corrosion resistance are provided. The coating film for aluminum elements comprises (i) chromium, (ii) zinc and (iii) cobalt and / or titanium with 95% by mass or more of said chromium being a trivalent chromium.

Owner:NIPPON HYOMEN KAGAKU KK

Carbon nano hollow-ball and its making method

The present invention relates to a carbon nano hollow sphere and its preparation method. Said method includes: using chromic compound to oxidize and polymerize aniline to form polyaniline and chromic hydroxide co-mixed precipitate, washing and drying to obtain the chromic hydroxide co-mixed precipitate, washing and drying to obtain the chromic hydroxide nano composite powder covered by polyaniline, under the condition of isolating air heating the polyaniline / chromic hydroxide nano composite powder to high-temp., making carbonization treatment to obtain the composite powder whose chromic hydroxide nano granule surface is covered with carbon, then dissolving said composite powder in acidic solution to remove chromic hydroxide to obtain the carbon nano hollow sphere which has the structure similar to carbon nano tube, can be used as hydrogen storing material or negative material of lithium ion cell.

Owner:SHANGHAI JIAO TONG UNIV

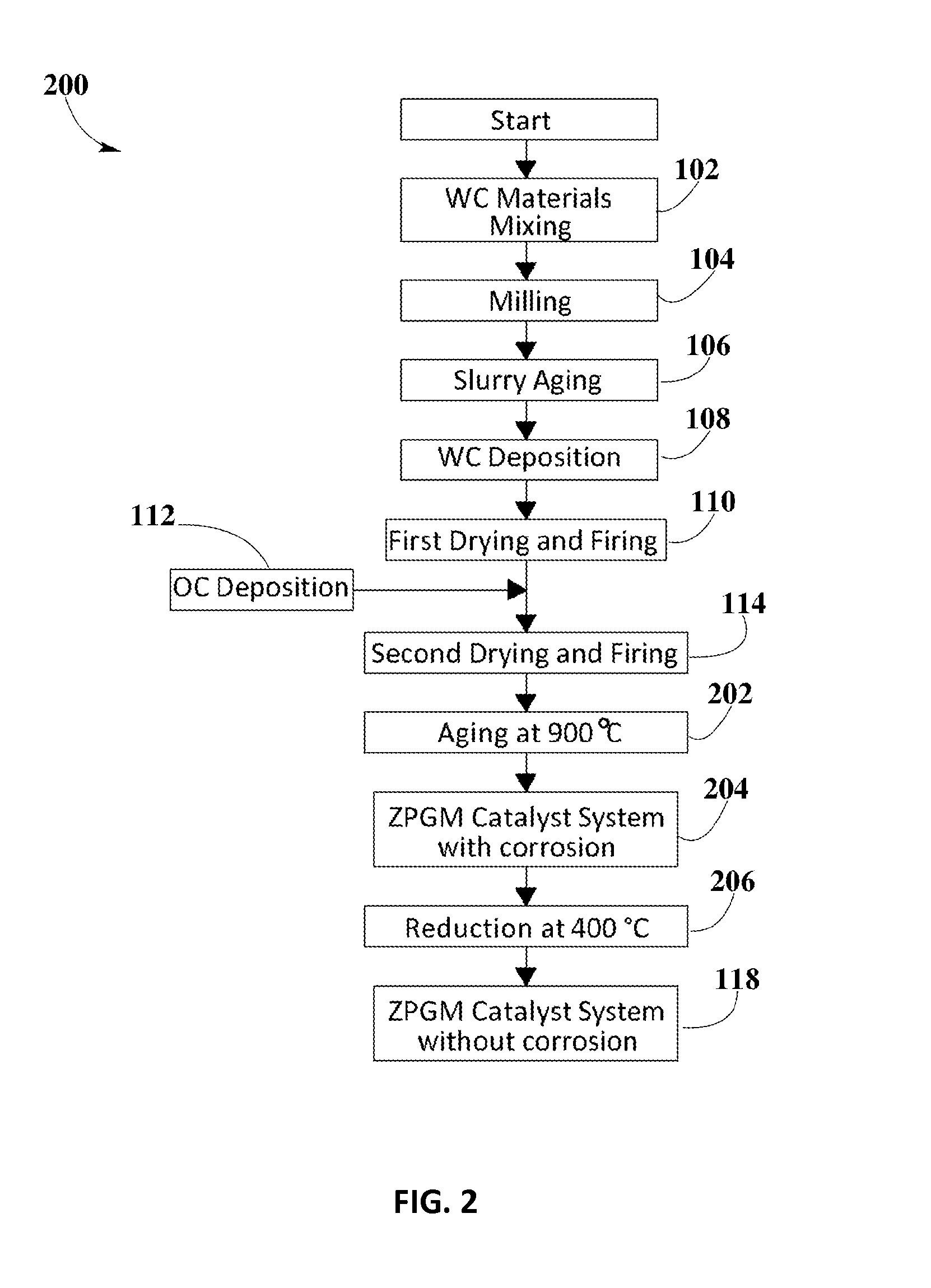

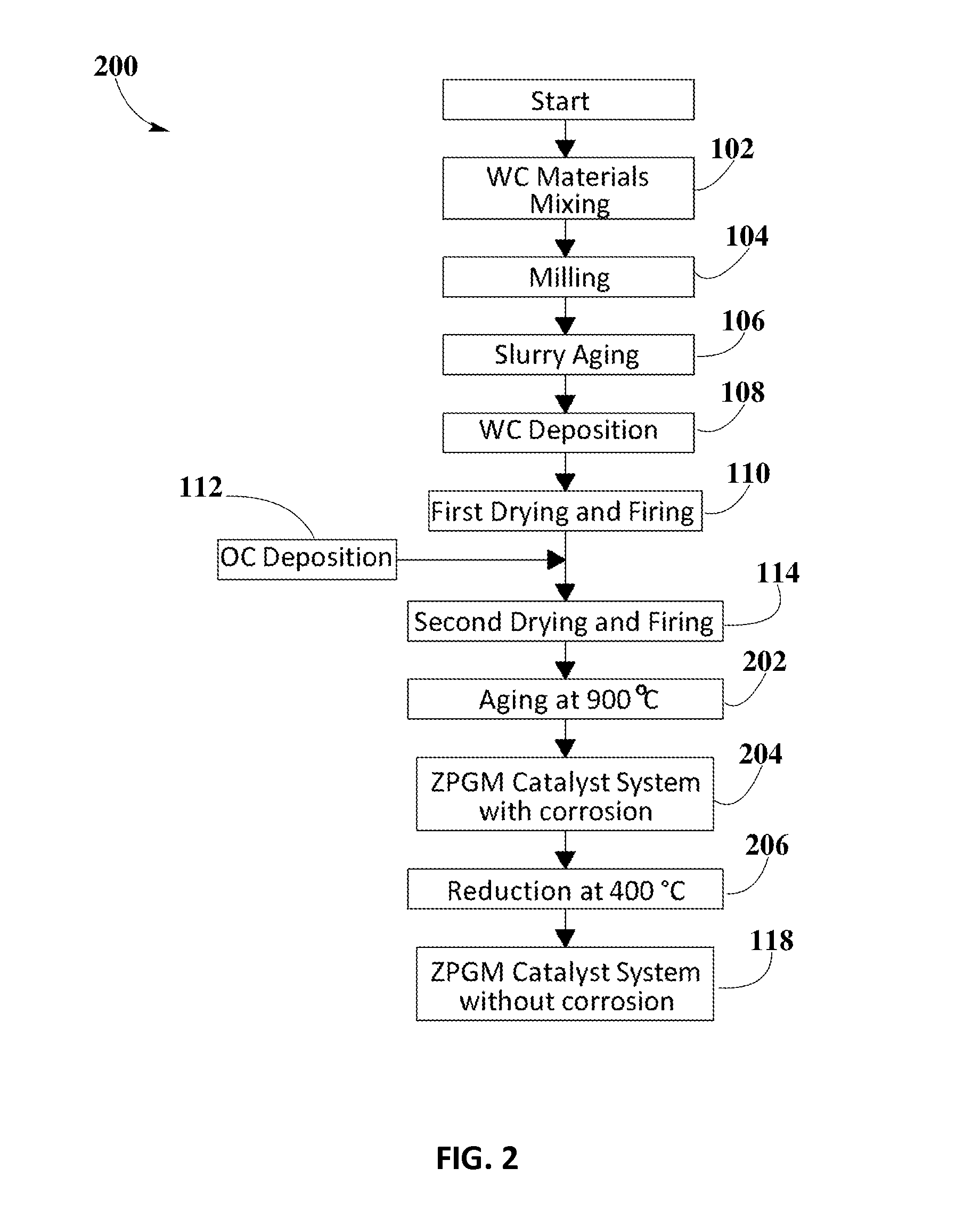

Process for Elimination of Hexavalent Chromium Compounds on Metallic Substrates within Zero-PGM Catalyst Systems

InactiveUS20150148220A1Inhibition formationHigh activityInorganic chemistryDispersed particle separationChromium CompoundsDecomposition

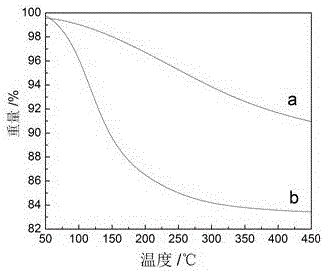

Process for manufacturing ZPGM catalysts systems that may allow the prevention of formation or the conversion of corrosion causing compounds, such as hexavalent chromium compounds, within ZPGM catalyst systems is disclosed. In one embodiment, disclosed ZPGM catalysts systems, may include metallic substrate, which may include alloys of iron and chromium, a washcoat and an overcoat. Disclosed manufacturing process may include a thermal decomposition of hexavalent chromium compounds which may allow the decomposition of such compounds into trivalent chromium compounds, and may also produce metallic catalyst, such as silver. Such conversion may prevent corrosion formation, such as red color corrosion within ZPGM catalyst system. An embodiment of the disclosed process may include a reducing agent, which may be present in exhaust conditions, which may convert hexavalent chromium compounds into trivalent chromium compounds as well as produce metallic catalyst, such as silver. Employing the disclosed manufacturing process may allow the production of ZPGM catalyst systems that may exhibit high activity and enhanced performance.

Owner:CLEAN DIESEL TECHNOLOGIES

Analysis of Occurrence of Corrosion Products with ZPGM and PGM Catalysts Coated on Metallic Substrates

InactiveUS20150050742A1Chemical analysis using catalysisAnalysis using chemical indicatorsHigh concentrationX-ray

The present disclosure provides identification techniques on platinum group metal (PGM) and zero platinum group metal (ZPGM) catalyst systems, in order to identify responsible materials for the formation of corrosion products, such as hexavalent chromium compounds. Identification analyses, such as X-ray diffraction analysis (XRD) and X-ray fluorescence (XRF) may be performed on various thermally treated PGM and ZPGM catalyst systems. Results of identification analyses may show that for both PGM and ZPGM catalysts, hexavalent chromium (Cr6+) may be formed during thermal aging at range of 600C to 900C. This may be due to the high concentration of chromium in substrate alloys. Therefore, occurrence of corrosion and production of hexavalent chromium may initiate from elements found in the substrate and not from elements within the PGM and ZPGM catalysts. Additionally, tests regarding washcoat adhesion and back pressure performed on disclosed PGM and ZPGM catalyst systems show that presence of corrosion products does not affect the quality of ZPGM and PGM catalyst systems.

Owner:CLEAN DIESEL TECHNOLOGIES

Etching liquid for conductive polymer, and method for patterning conductive polymer

InactiveUS20100089872A1Improve etching effectDecorative surface effectsPrinted circuit aspectsHydrogen halidePermanganic acid

The object is to provide an etching liquid for a conductive polymer having excellent etching capability toward a conductive polymer, and a method for patterning a conductive polymer employing the etching liquid for a conductive polymer. The conductive etching liquid of the present invention is selected from the group consisting of (1) an etching liquid comprising greater than 0.5 wt % but no greater than 70 wt % of (NH4)2Ce(NO3)8 or at least 0.5 wt % but no greater than 30 wt % of Ce(SO4)2, (2) an etching liquid comprising greater than 0.5 wt % but no greater than 30 wt % of (NH4)4Ce(SO4)4, (3) an etching liquid comprising a hypochlorous acid salt aqueous solution having an effective chlorine concentration of at least 0.06 wt % and a pH of greater than 3 but less than 8, (4) an etching liquid comprising nitrosyl chloride which comprises at least 5 wt % of hydrochloric acid and at least 20 wt % of nitric acid, a (hydrochloric acid concentration+0.51×nitric acid concentration) value being no greater than 35 wt %, and a (hydrochloric acid concentration+0.5×nitric acid concentration) value being at least 30 wt %, (5) an etching liquid comprising at least 3 wt % but no greater than 40 wt % of a bromic acid compound and at least 4 wt % of an inorganic acid, (6) an etching liquid comprising at least 6 wt % but no greater than 40 wt % of a chloric acid compound and at least 7 wt % of a hydrogen halide, (7) an etching liquid comprising at least 0.001 wt % but no greater than 20 wt % of a permanganic acid compound, and (8) an etching liquid comprising at least 3 wt % but no greater than 30 wt % of a hexavalent chromium compound.

Owner:TSURUMISODA +1

Method for Making and Using Chromium III Salts

ActiveUS20100300891A1ChromatisationSolid state diffusion coatingChromium Hexavalent CompoundAlkali metal

A method of preparing an aqueous composition of a chromium III compound, comprising adding hydrogen peroxide to a mixture comprising water and a chromium VI compound in the presence of at least one acid according to the formula H2GF6, in which G is a Group IV-B element. The composition may contain less than 500 ppm of alkali metal ions and less than 200 ppm of halide ions, relative to chromium and may test negative for chromium VI using s-diphenylcarbazide. The composition may be used for treating a metal surface, among other applications.

Owner:BULK CHEM

Surface treatment method of nickel metal strip for lithium-ion battery negative electrode ear

InactiveCN103194743AImprove soldering effectCorrosion resistanceMetallic material coating processesCell component detailsElectrical batteryAdhesive

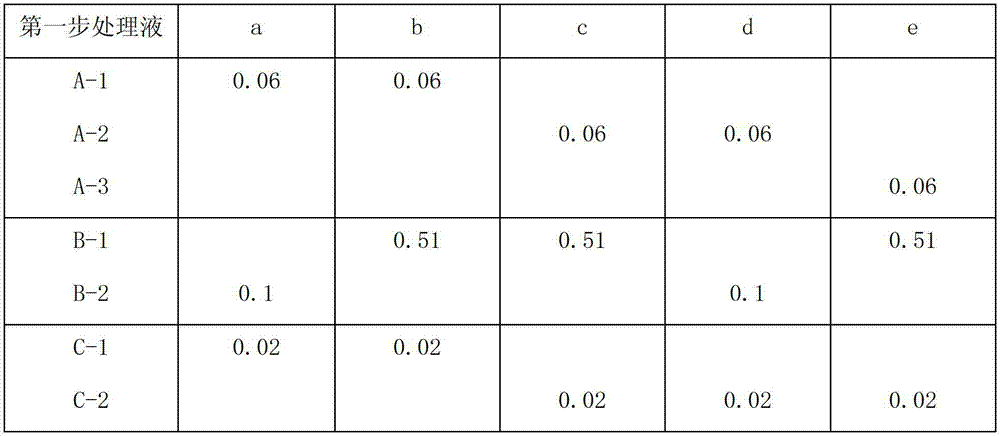

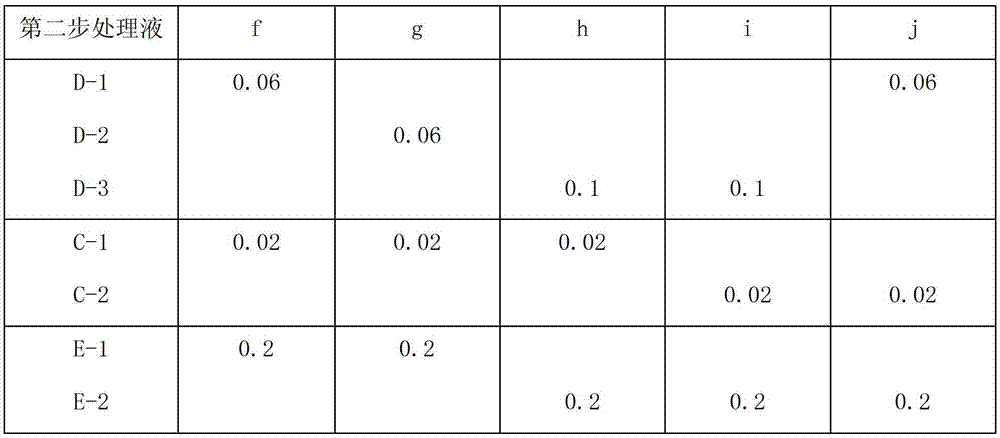

The present invention discloses a surface treatment method of a nickel metal strip for a lithium-ion battery negative electrode ear. The method includes two steps. A treatment liquid in a first step includes at least a hexavalent chromium compound, a fluorine compound, and a phosphorus compound. A treatment liquid in a second step includes at least organic acid, inorganic acid, and a fluorine compound. A chemical conversion film is formed by heating and drying after applying the treatment liquid on the surface of the nickel metal strip. The nickel metal strip treated by the method of the present invention after hot pressing with an ear adhesive has excellent electrolyte resistance property. The nickel metal strip is directly immersed in the electrolyte at 85 DEG C for 4.5 hours. The bonding strength is almost unchanged. Meanwhile, the nickel metal strip after treatment still has good soldering properties, and can be directly soldered on the surface thereof. The metal nickel strip is used for the production of lithium ion battery ears. The production process can be simplified. The cost is reduced.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for calcium-free calcination production of sodium chromate and chromium-containing cast iron as co-product

InactiveCN103224253AAvoid loopsEffective control of side effectsChromates/bichromatesFiltrationMixed materials

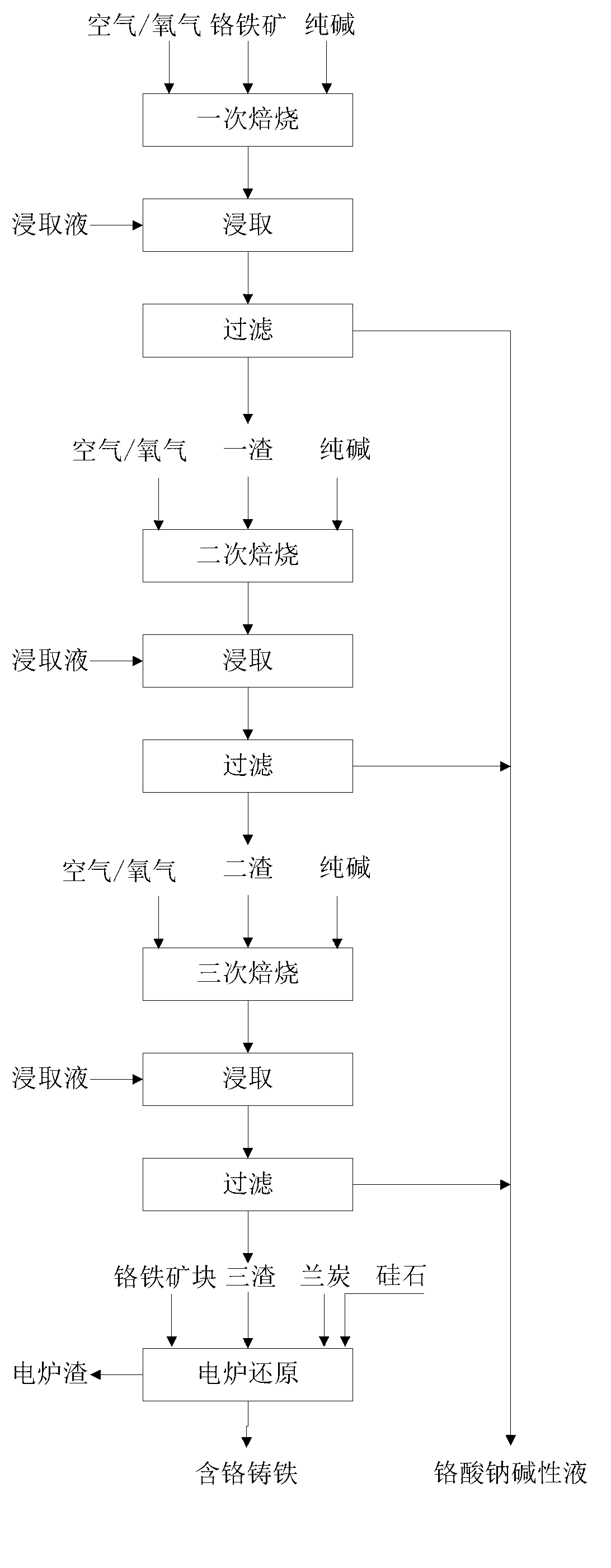

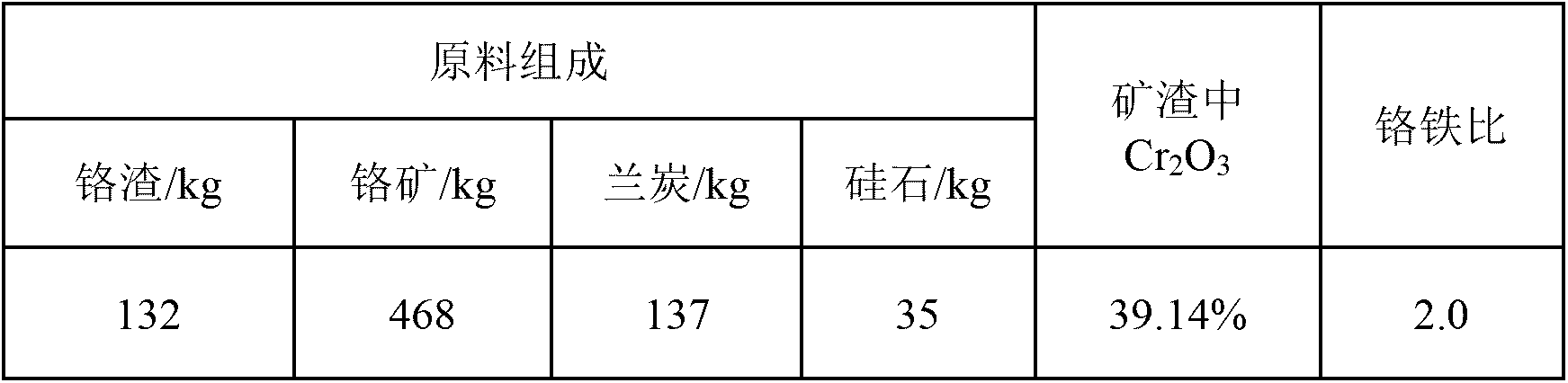

The invention discloses a method for calcium-free calcination production of sodium chromate and chromium-containing cast iron as a co-product. The method comprises the following steps of 1, first-stage calcination by mixing chromite and soda ash according to a certain ratio to obtain a first-stage mixed material, wherein a soda ash use amount is 35-60% of the theoretical alkali use amount, putting the first-stage mixed material into a rotary kiln, carrying out oxidizing calcination, and carrying out impregnation and filtration of the calcined clinker to obtain a first-stage sodium chromate alkali solution and filter residues, and 2, treating the filter residues, and carrying out second-stage calcination and third-stage calcination of the filter residues by the step 1 to obtain second-stage calcination filter residues, third-stage calcination filter residues, a second-stage calcination sodium chromate alkali solution and a third-stage calcination sodium chromate alkali solution, wherein the third-stage calcination filter residues can be used for co-production of chromium-containing cast iron. The method does not adopt any auxiliary materials in calcination, and effectively avoids ring forming of the rotary furnace. The calcination residues obtained by the method does not contain hexavalent chromium compounds and thus chromium residue harmlessness and recycling are realized. Through co-production of high-carbon chromium iron, a chromium comprehensive use ratio is improved by more than 95%. Through smelting, produced electroslag does not contain hexavalent chromium so that thorough detoxification of chromium residues is realized.

Owner:INNER MONGOLIA CHROMIUM

Nano composite carbon/chromium trioxide powder and its prepn

The present invention relates to nano composite carbon / chromium trioxide powder and its preparation. Polyaniline is oxide with hexad chromium compound to form the mixture precipitate of polyaniline and chromium hydroxide; the mixture precipitate is washed and dried to obtain nano composite polyaniline / chromium hydroxide powder; and under air isolating condition, the nano composite polyaniline / chromium hydroxide powder is heated to high temperature to obtain the nano composite carbon / chromium trioxide powder with carbon coating the nano chromium trioxide particle. The nano composite carbon / chromium trioxide powder of the present invention has small particle size and raised use effect as antiwear additive and is suitable for large-scale production.

Owner:SHANGHAI JIAO TONG UNIV

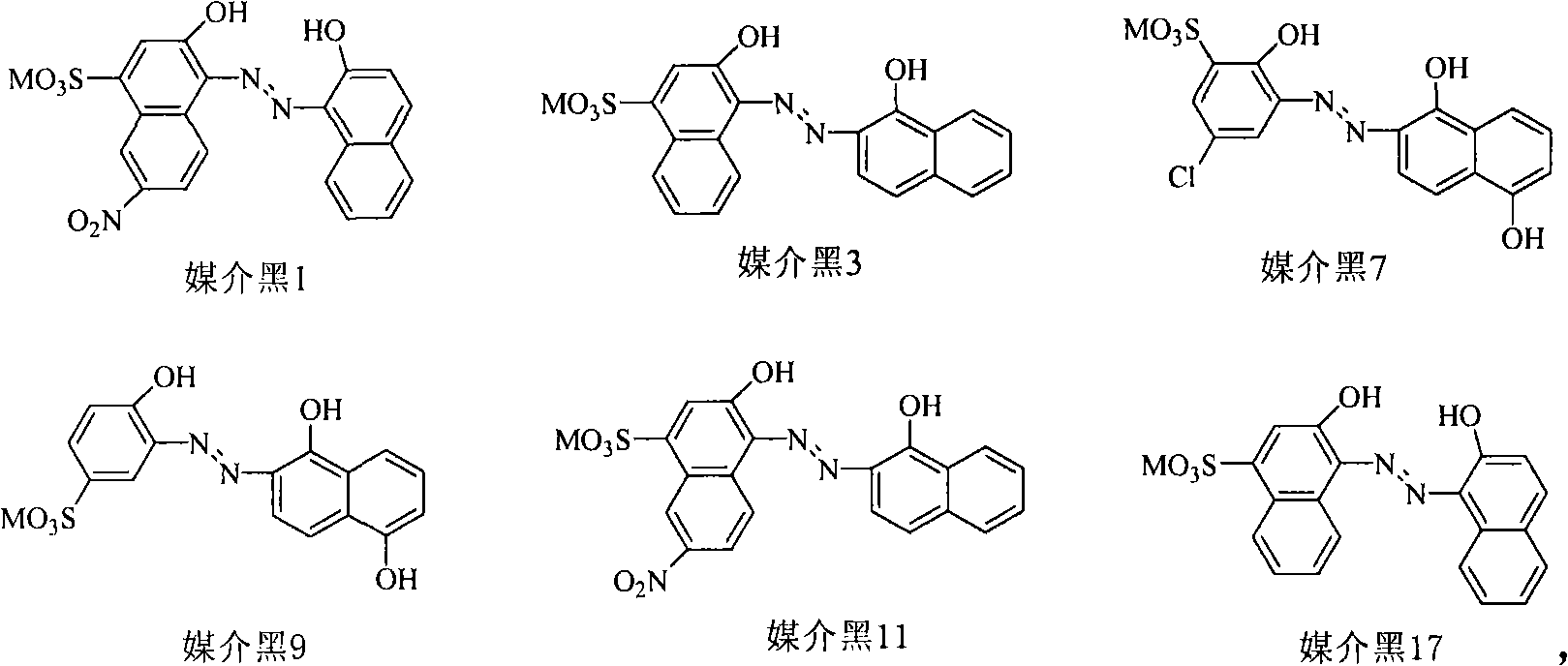

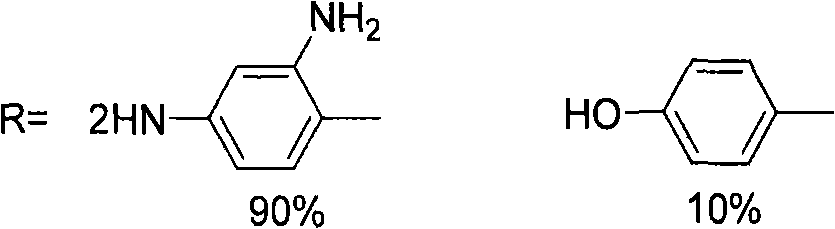

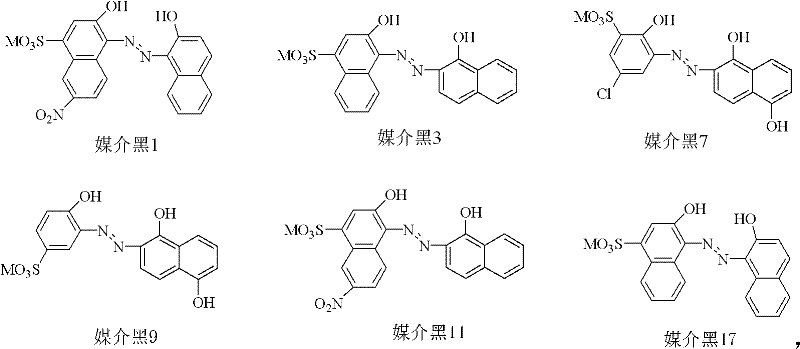

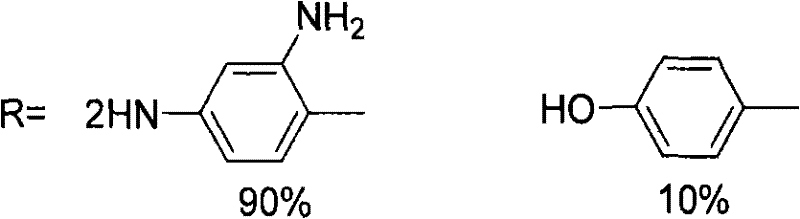

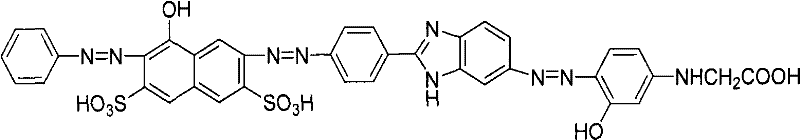

Chrome complex dye as well as preparation method and applications thereof

ActiveCN101665628AGood weather resistanceSolve the problem of poor weather fastnessNon-macromolecular organic additionInksWeather resistanceWater soluble

The invention relates to a chrome complex dye containing a mordant black dye and a chrome complex, wherein the chrome complex is formed as follows: using a hexavalent chromium compound, or a mixture of the hexavalent chromium compound and a trivalent chromium to oxidize the mordant black dye to generate the black chrome complex dye. The chrome complex dye has excellent weather resistance and watersolubility and can be used as colorant of ink-jet printing ink, oil ink, coating, paint, toner of laser printing, and the like.

Owner:DALIAN UNIV OF TECH +1

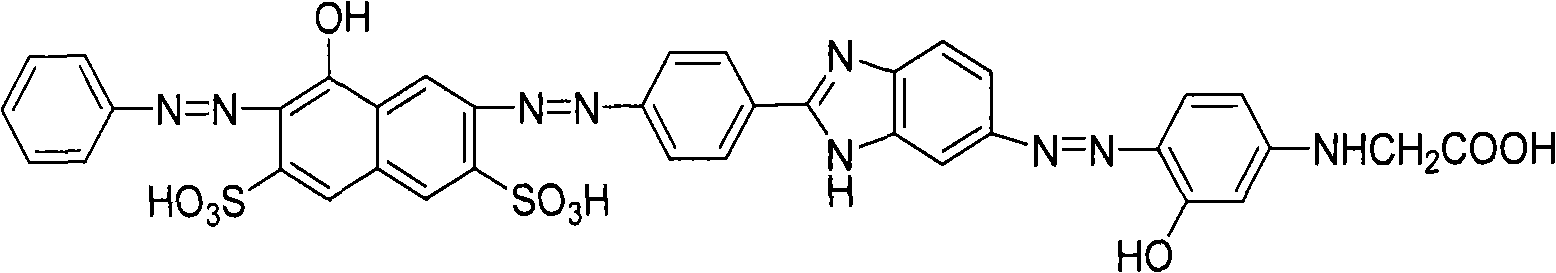

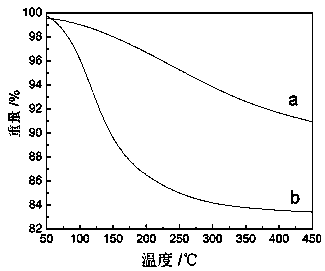

Chromium-free environment-friendly insulating coating for oriented silicon steel

InactiveCN106189459AAvoid pollutionDamage to healthFireproof paintsAnti-corrosive paintsChromium freePhosphate

The invention discloses a chromium-free environment-friendly insulating coating for oriented silicon steel. The chromium-free environment-friendly insulating coating is prepared from the following components in percentage by mass: 1 to 7 percent of tungstate, 1 to 5 percent of titanyl sulfate, 25 to 50 percent of aqueous solution of dihydric phosphate, 25 to 50 percent of silica sol and 10 to 40 percent of deionized water, wherein the sum of mass percents is 100 percent, and the sum of the contents of the tungstate and the titanyl sulfate is 2 to 8 percent of total mass of the coating. After the oriented silicon steel is coated with the coating, baking, sintering and curing need to be performed in protective atmosphere such as N2 or Ar. The insulating coating disclosed by the invention does not contain hexavalent chromium compounds harmful to a human body and environment, and belongs to an environment-friendly product, and has the advantages of good insulating property, corrosion resistance, adhesive property, high temperature resistance and the like; in addition, an iron loss value of the oriented silicon steel can be reduced, and a coating layer does not get tacky after being placed in a room temperature environment for a long time.

Owner:FUZHOU UNIV

Spray chrome oxide preparation method

InactiveCN103241774AShort calcination timeReduce energy consumptionChromium trioxideReaction temperatureChromium Hexavalent Compound

The invention relates to a spray chrome oxide preparation method, belongs to the inorganic material preparation field, and especially relates to a spray chrome oxide preparation method through a hydrothermal process. The method is characterized in that an oxidant is a hexavalent chromium compound, a reductant is micro-molecular alcohol or aldehyde, and a surfactant is polyol or polyprotic acid; and the method comprises following steps: mixing the reductant, the oxidant, the surfactant and water according to a reductant / oxidant ratio of 1-5(mol / mol) and a surfactant / oxidant ratio of 0.001-0.5(mol / mol), reacting at a constant reaction temperature of 100-300DEG C under an initial hydrothermal condition for a reaction period below 120min, washing the obtained precipitate, drying, and calcining at 800-1200DEG C for a period below 2h to obtain spherical micrometer controlled-spray chrome oxide. The method has the advantages of simple technology, realization of the calcining period far lower than that of present patents, less energy consumption, and popularization deserving.

Owner:HEBEI UNIV OF ENG

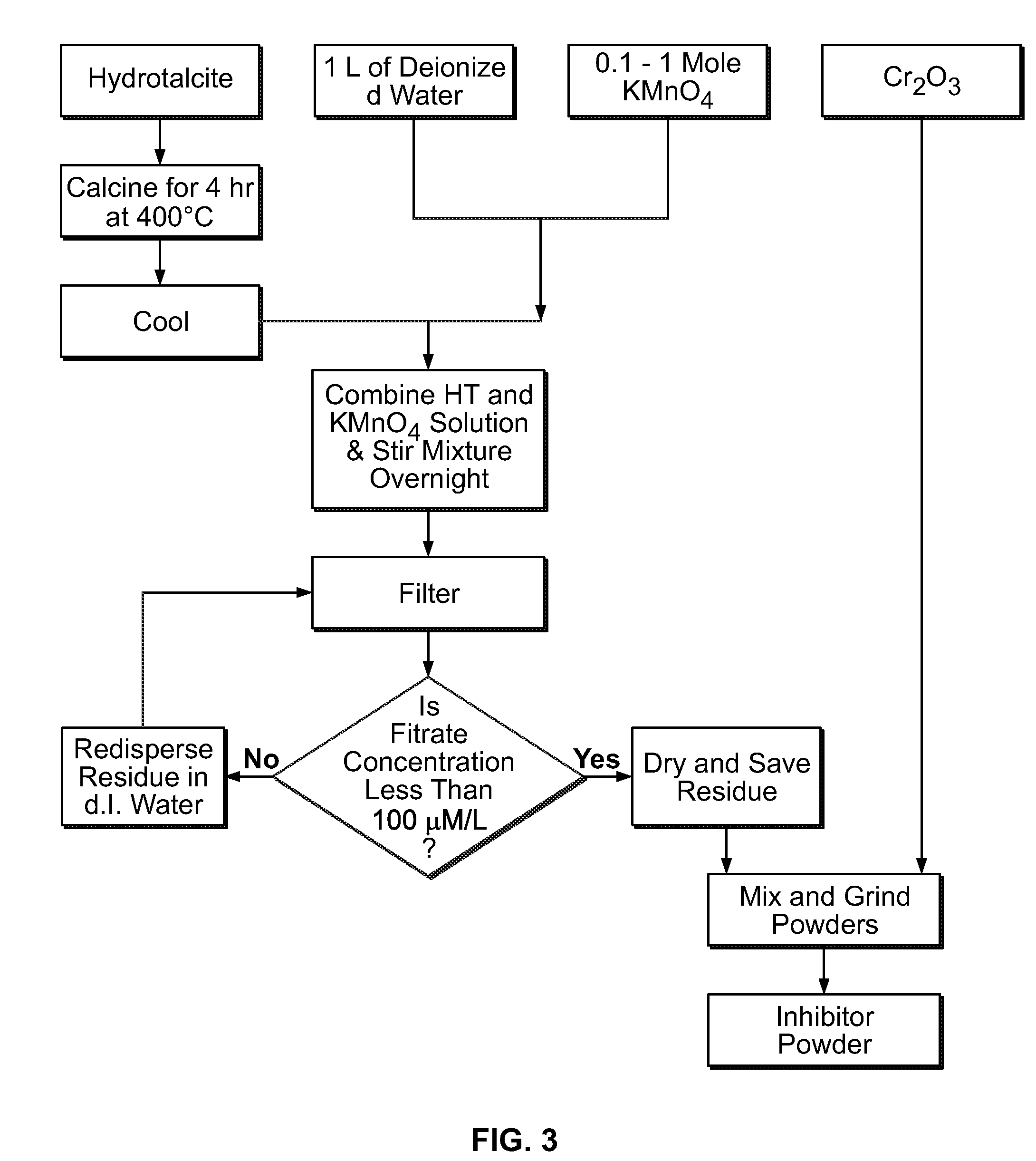

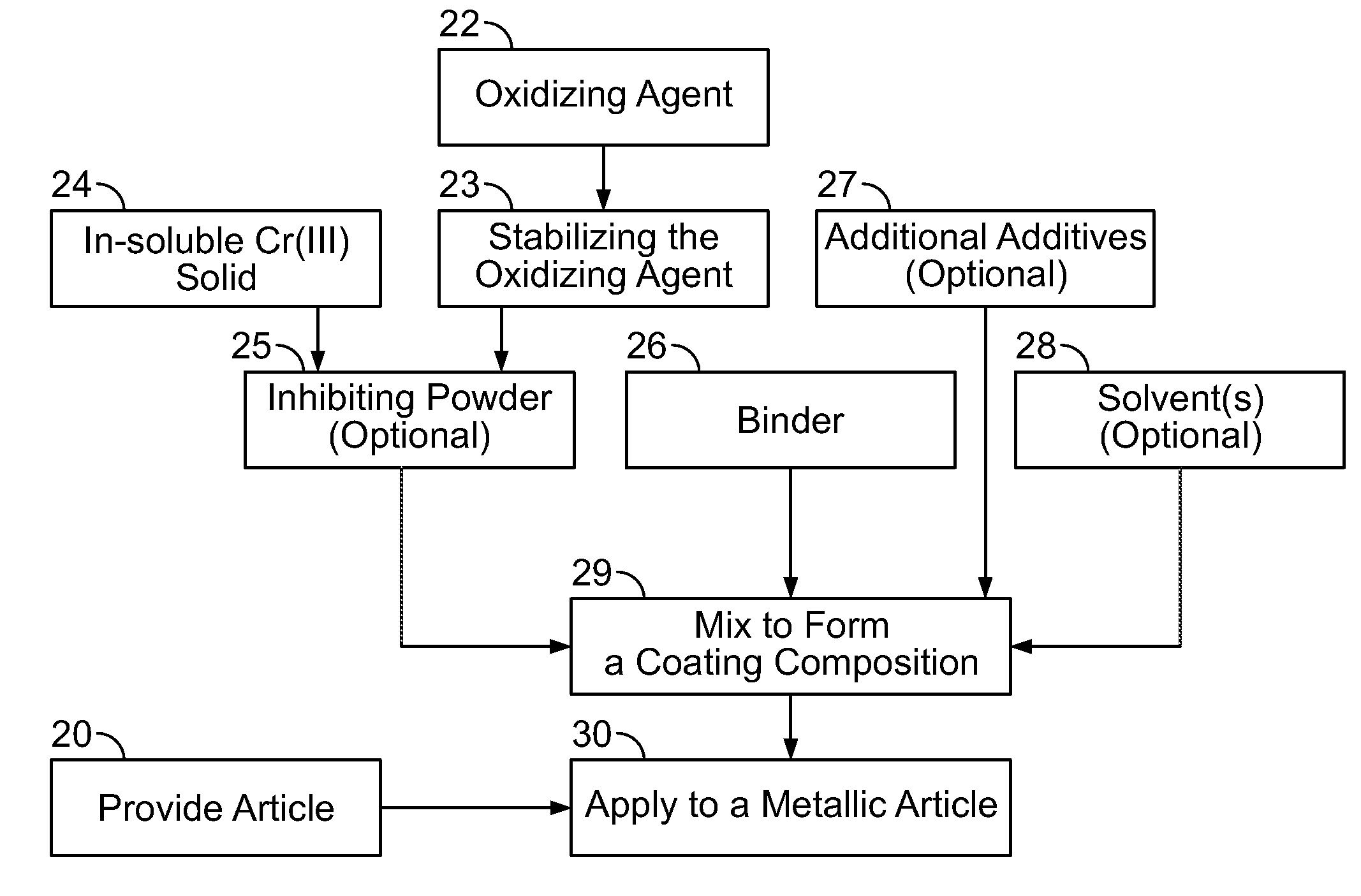

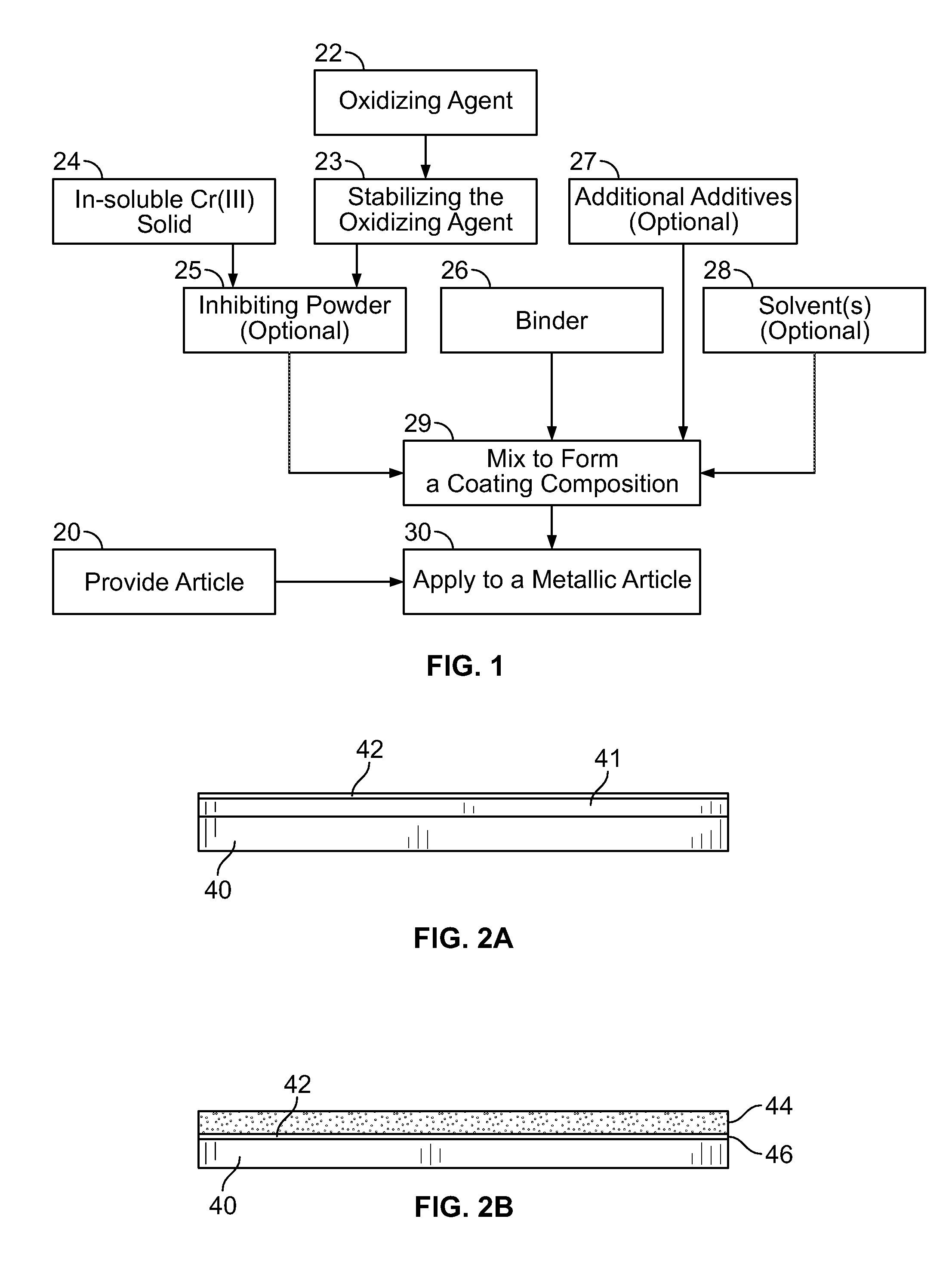

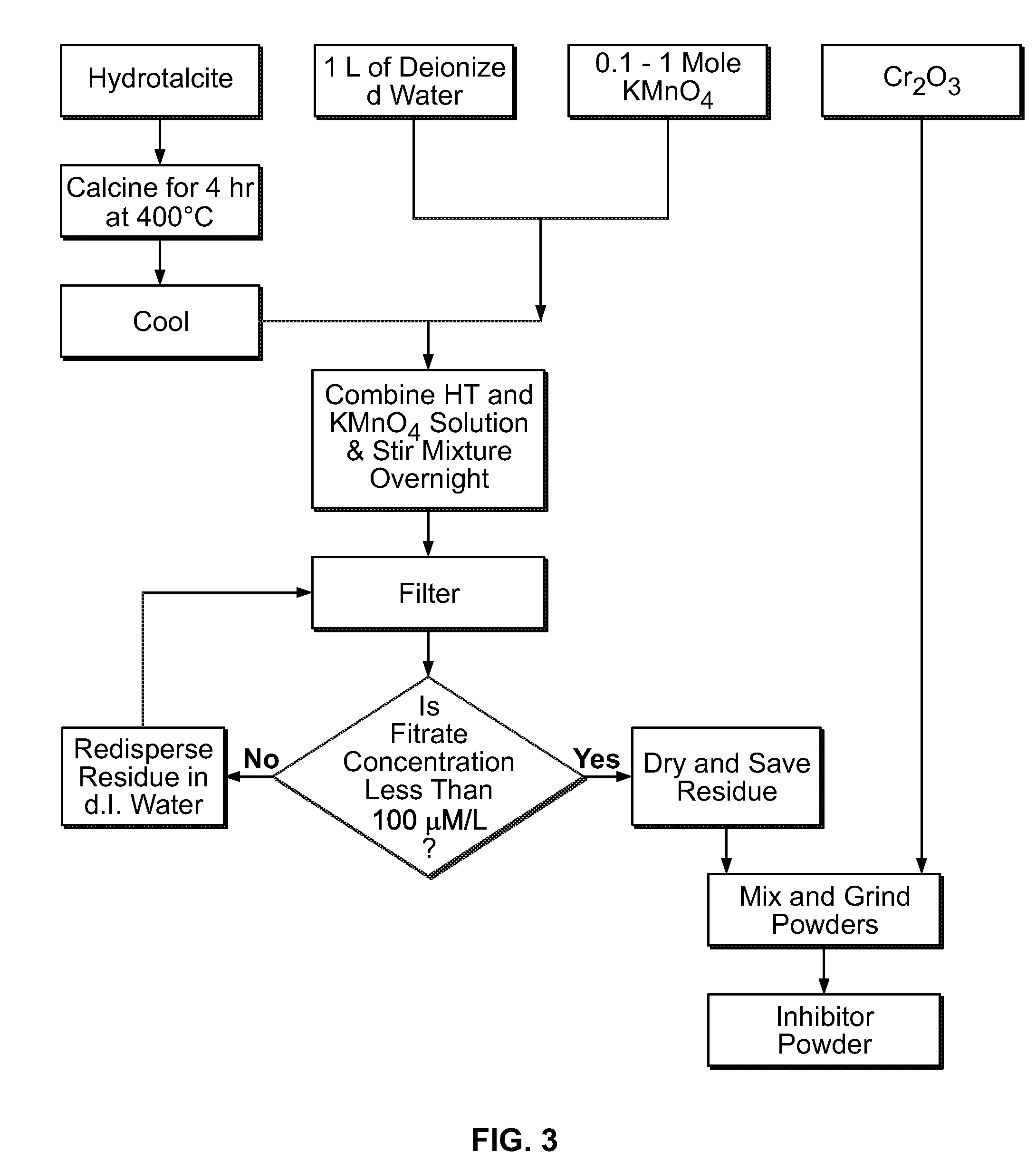

Chromate-generating corrosion inhibitor

InactiveUS7691498B2Enabling useOther chemical processesHeat-exchange elementsWater solubleChromium Hexavalent Compound

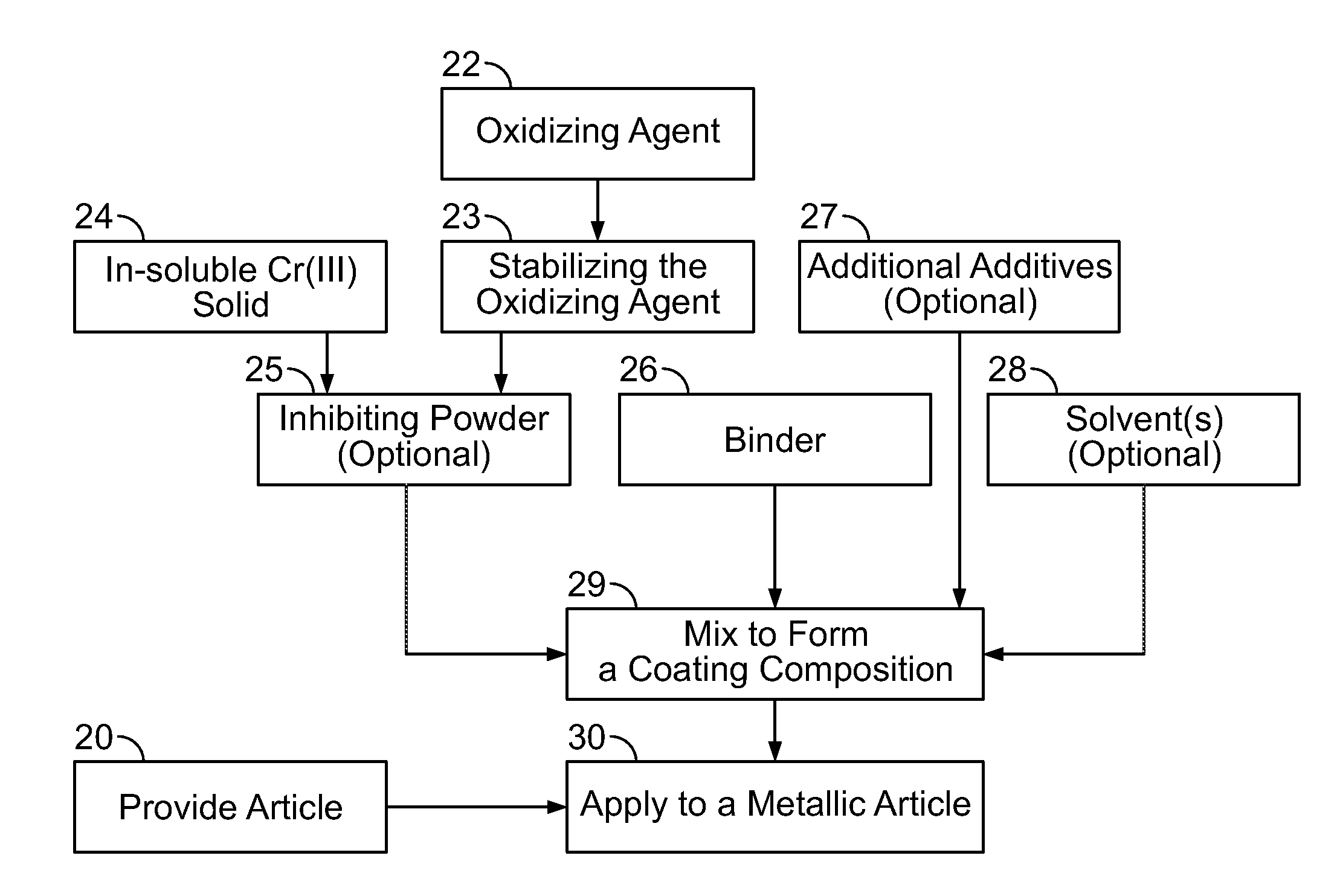

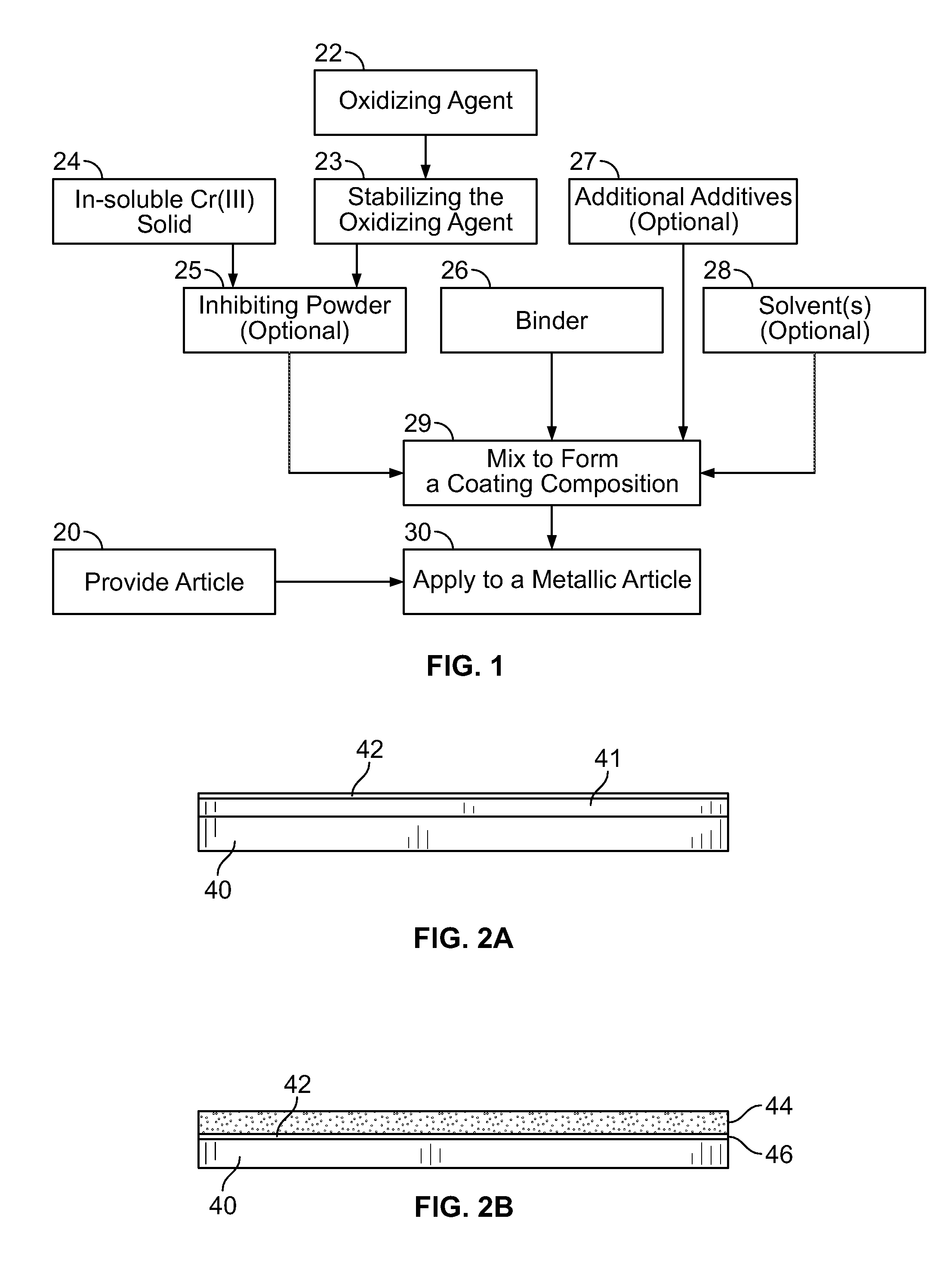

A coating composition is disclosed that includes a binder, a tri-valent chromium solid, and a stabilized oxidizing agent. The coating composition is used in a method to protect a surface of a metallic article, such as an aluminum article. The tri-valent chromium solid forms a soluble hexavalent chromium compound as a result of reaction with the oxidizing agent when activated in the presence of a corrosive environment. The released water soluble hexavalent chromium migrates to coating defects to protect the metallic article.

Owner:THE BOEING CO

Method for detoxicating chromium residues and comprehensive utilization of detoxicated chromium residues

InactiveCN102189093BSave land resourcesSolid waste managementSolid waste disposalSlurryChromium Hexavalent Compound

The invention relates to a method for detoxicating chromium residues and the comprehensive utilization of the detoxicated chromium residues. The method for detoxicating the chromium residues comprises the following steps of: performing wet ball milling on chromium-containing waste residues to obtain chromium residue powder; adding water into the chromium residue powder to prepare chromium residue slurry; adding acid into the chromium residue slurry to prepare chromium residue slurry solution, and fully stirring the chromium residue slurry solution simultaneously to make the chromium residue slurry immersed in the acid; adding a reducing agent into the immersed chromium residue slurry solution until hexavalent chromium does not exist in the immersed chromium residue slurry solution; curing the chromium residue slurry solution without the hexavalent chromium, and performing solid-liquid separation; and drying and grinding filter residues to obtain the detoxicated chromium residues without the hexavalent chromium. By the method for detoxicating the chromium residues, various hexavalent chromium compounds contained in the chromium residues can be systematically and completely detoxicated and removed, the hexavalent chromium in various produced building material products is comprehensively utilized, and the content of extract is less than 0.1mg / L.

Owner:刘杰

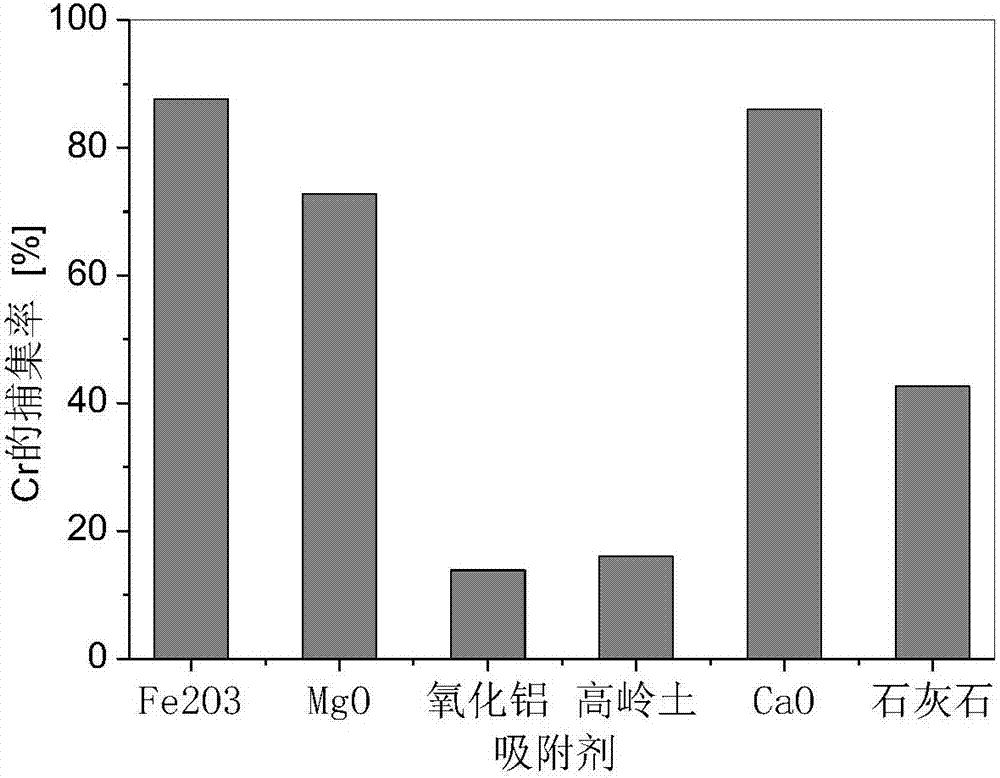

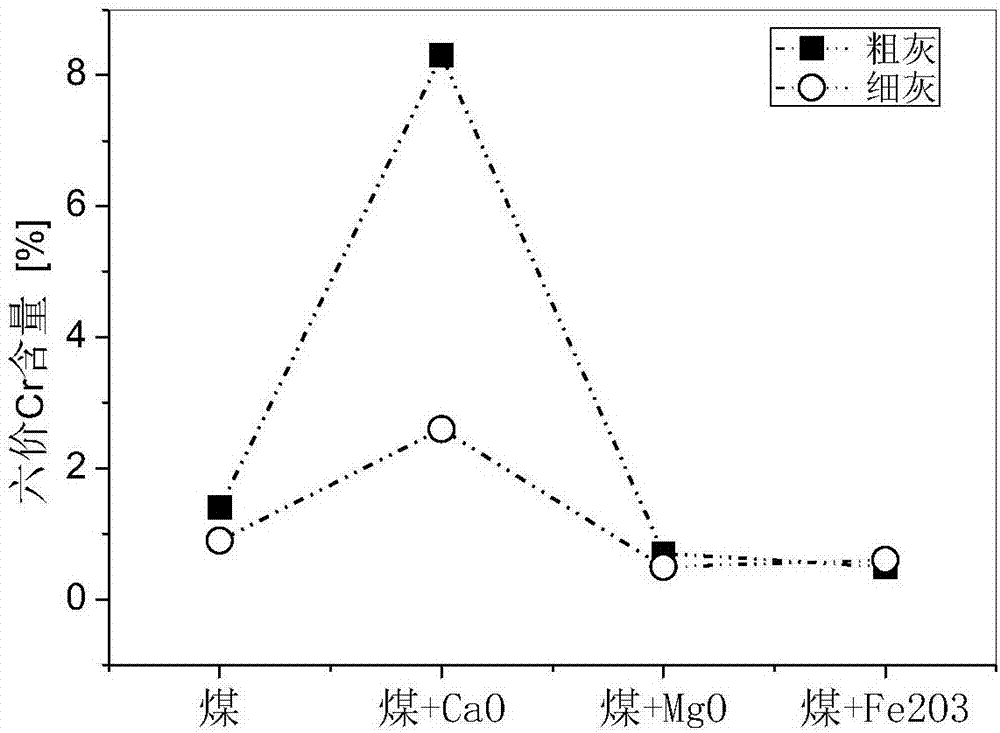

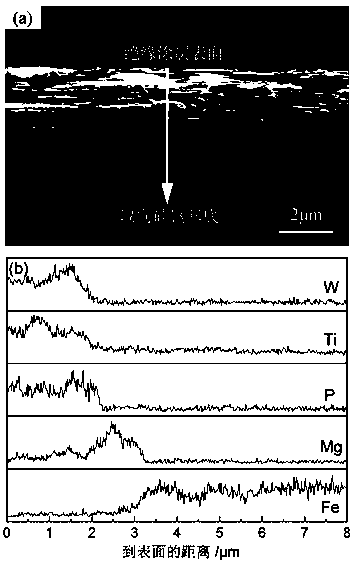

Method for reducing emission of heavy metal chromium in burning process

ActiveCN107537310AAvoid mass generationSimple processing methodOther chemical processesDispersed particle separationChemical reactionHazardous substance

The invention discloses a method for reducing emission of heavy metal chromium in a burning process. The method comprises the following steps: injecting 1g / Nm<3> to 20g / Nm<3> of main adsorbent based on Fe or Mg into tail flue gas of a high temperature (800 to 1100 DEG C) of a burning apparatus, wherein the adsorbent is solid powder, and a particle size of the adsorbent is 5 to 100 micrometers. Byvirtue of the chemical reaction and physical adsorption effect, Cr in the flue gas is adsorbed and can be converted into solid particles with an aerodynamic size being greater than 2.5 micrometers atthe high temperature, so that the Cr can be easily removed by a dust removal apparatus, and the generation of highly-toxic hexavalent chromium compounds in the ash can be inhibited. Gaseous toxic andharmful substances are converted to large-particle solids insoluble in water, so that the capturing and harmless and recycling treatment can be facilitated.

Owner:SHANDONG UNIV

Chromium plating method

A chromium plating method wherein an article to be plated is immersed in an acidic chromium electroplating bath and electrolysis is carried out using a positive electrode that has an iridium oxide-containing film at least on the surface. The acidic chromium electroplating bath contains a trivalent chromium compound and a hexavalent chromium compound at a ratio such that the total chromium concentration of trivalent chromium and hexavalent chromium is 60-140 g / L, the hexavalent chromium concentration is 5-40 g / L, and the ratio of the hexavalent chromium concentration is 5-35% by mass of the total chromium concentration, while containing 50-400 g / L of organic carboxylate ions and having a lead ion concentration of not more than 2 mg / L. By the method, a chromium plating film that is good and stable over a long time period can be obtained. In addition, the plating bath can be controlled extremely easily in the chromium plating method.

Owner:C UYEMURA & CO LTD

Method for extracting hexavalent chromium compound from polymer material

InactiveCN102515274AWill not cause mutual conversionEasy to operateChromium compoundsOrganic solventMutual transformation

The invention discloses a method for extracting hexavalent chromium from a polymer. Organic solvents such as acetone and tetrahydrofuran are selected and used to fully dissolve the polymer; a sodium hydroxide or potassium hydroxide aqueous solution with a mass fraction of 0.5 percent to 10 percent is added to the polymer, is fully mixed with the polymer and then stand still until layering, and a lower layer aqueous solution is taken out; a sodium hydroxide or potassium hydroxide aqueous solution with a mass fraction of 0.5 percent to 10 percent is re-added into an upper layer organic solution, is fully mixed with the upper layer organic solution and stands still until layering, and a lower layer aqueous solution is re-taken out; and an aqueous solution fully extracting soluble hexavalent chromium and insoluble hexavalent chromium can be obtained only by combining the two lower layer aqueous solutions. The method has the following beneficial effects that: firstly, by adopting the method, the soluble hexavalent chromium and the insoluble hexavalent chromium in a polymer material can be fully extracted; secondly, mutual transformation of chromium valence states in the original compound cannot be caused when the soluble hexavalent chromium and the insoluble hexavalent chromium are extracted by adopting the method; and thirdly, the method has the characteristic that the operation is simple.

Owner:SHENZHEN ENTRY EXIT INSPECTION & QUARANTINE BUREAU INDAL PROD INSPECTION TECH CENT

Chromate-generating corrosion inhibitor

InactiveUS20090269616A1Enabling useOther chemical processesHeat-exchange elementsWater solubleChromium Hexavalent Compound

Owner:THE BOEING CO

Method for extracting soluble hexavalent chromium compounds from polymer materials

InactiveCN102494926AEasy to detectWill not cause mutual conversionPreparing sample for investigationChromium compoundsInorganic saltsOrganic solvent

The invention discloses a method for completely extracting soluble hexavalent chromium from polymers and keeping valence states of chromium in original compounds unchanged. Firstly, tetrahydrofuran or acetone soluble polymers of organic solvents are used; and secondly, saturated inorganic salt solution is used for re-extracting the hexavalent chromium twice to combine a water layer. The method has the remarkable advantages that (1) the method can be used for completely extracting the soluble hexavalent chromium from polymer materials; (2) the method avoids mutual transformation of the valence states of the chromium in the original compounds while extracting the soluble hexavalent chromium, and is beneficial to detection of the content of the hexavalent chromium; and (3) the method is simple in operation.

Owner:SHENZHEN ENTRY EXIT INSPECTION & QUARANTINE BUREAU INDAL PROD INSPECTION TECH CENT

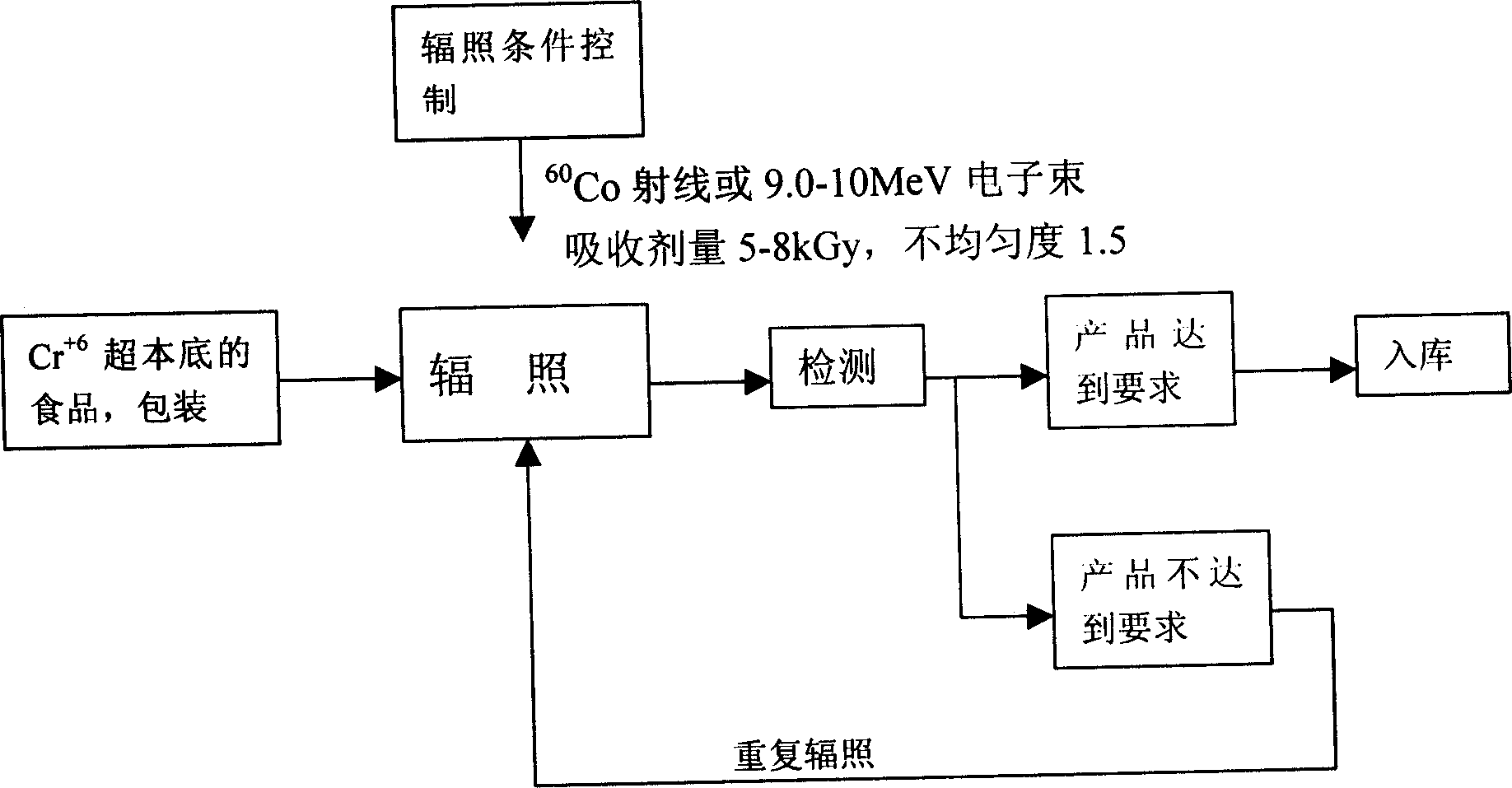

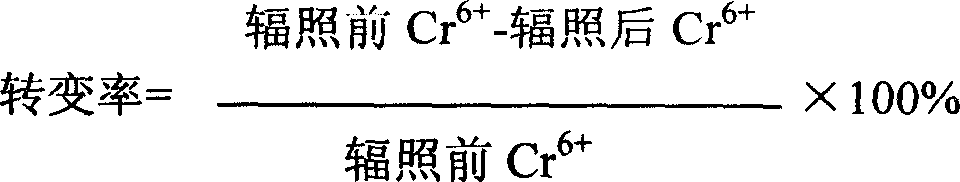

Method of ray irradiation for reducing chromic ion valence state in foodstuff

InactiveCN1907092AImprove securityImprove hygiene qualityFood preparationChromium Hexavalent CompoundNatural abundance

The invention discloses a ray irradiating method to reduce chromic ion valent state in the food in the irradiating manufacturing domain, which is characterized by the following: the positive hexavalent chromium compounds are applied widely in the industry, which is easy to pollute; the method reduces natural background value to reduce harm for human and animal, which avoids skin cancer and lung carcinoma.

Owner:宁波超能科技股份有限公司

Simple method for preparing sprayed chrome oxide

InactiveCN104709942AShort calcination timeReduce energy consumptionChromium oxides/hydratesReaction temperatureChromium Hexavalent Compound

The invention belongs to the field of inorganic material preparation and especially relates to a method for preparing sprayed chrome oxide by a surfactant-free hydrothermal method. The method is characterized in that a used oxidizing agent is a metal cation-containing hexavalent chromium compound and a used reducing agent is small molecular alcohol or aldehyde, the reducing agent, the oxidizing agent and water are blended according to oxidizing agent concentration of 40g / l or more and a mole ratio of the reducing agent to the oxidizing agent of 0.2-5, then the reaction system undergoes a reaction at a constant reaction temperature of 140-300 DEG C under hydrothermal conditions for some time and generally for less than 120min, and the precipitates are washed, dried and calcined to form spherical micron-sized sprayed chrome oxide, wherein a calcining temperature is generally in a range of 800-1200 DEG C and calcining time is generally less than 2h. The method has simple processes, is superior to the prior art, and has low energy consumption and a good popularization value.

Owner:HEBEI UNIV OF ENG

A chromium-free environment-friendly insulating coating for oriented silicon steel

InactiveCN106189459BAvoid pollutionDamage to healthFireproof paintsAnti-corrosive paintsChromium freeTungstate

The invention discloses a chromium-free environment-friendly insulating coating for oriented silicon steel. The chromium-free environment-friendly insulating coating is prepared from the following components in percentage by mass: 1 to 7 percent of tungstate, 1 to 5 percent of titanyl sulfate, 25 to 50 percent of aqueous solution of dihydric phosphate, 25 to 50 percent of silica sol and 10 to 40 percent of deionized water, wherein the sum of mass percents is 100 percent, and the sum of the contents of the tungstate and the titanyl sulfate is 2 to 8 percent of total mass of the coating. After the oriented silicon steel is coated with the coating, baking, sintering and curing need to be performed in protective atmosphere such as N2 or Ar. The insulating coating disclosed by the invention does not contain hexavalent chromium compounds harmful to a human body and environment, and belongs to an environment-friendly product, and has the advantages of good insulating property, corrosion resistance, adhesive property, high temperature resistance and the like; in addition, an iron loss value of the oriented silicon steel can be reduced, and a coating layer does not get tacky after being placed in a room temperature environment for a long time.

Owner:FUZHOU UNIV

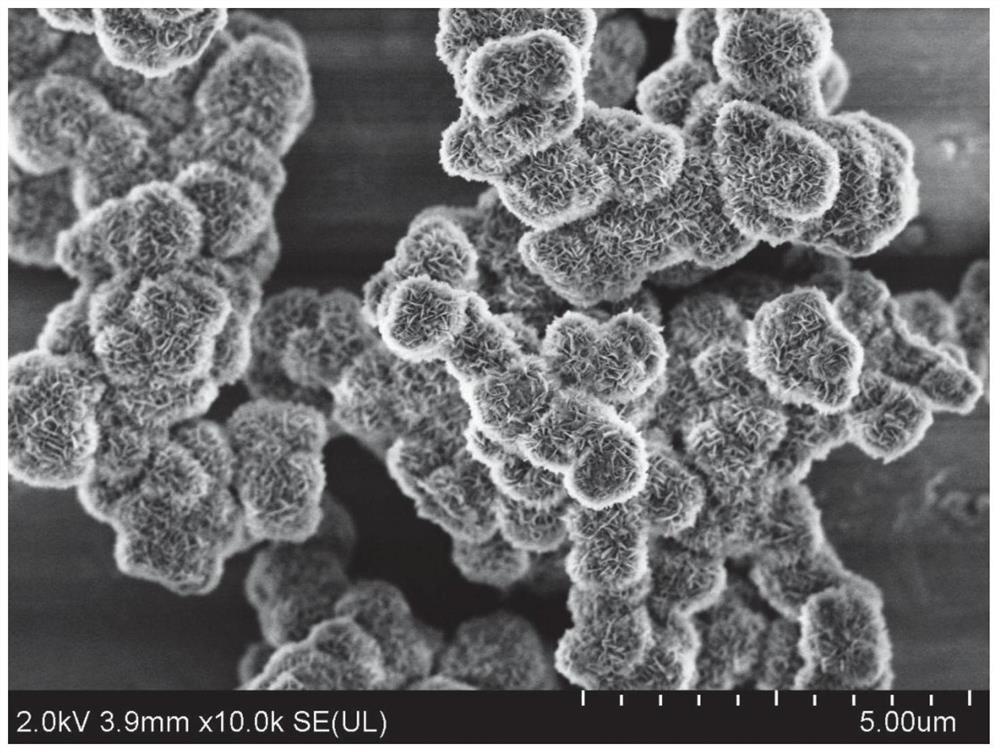

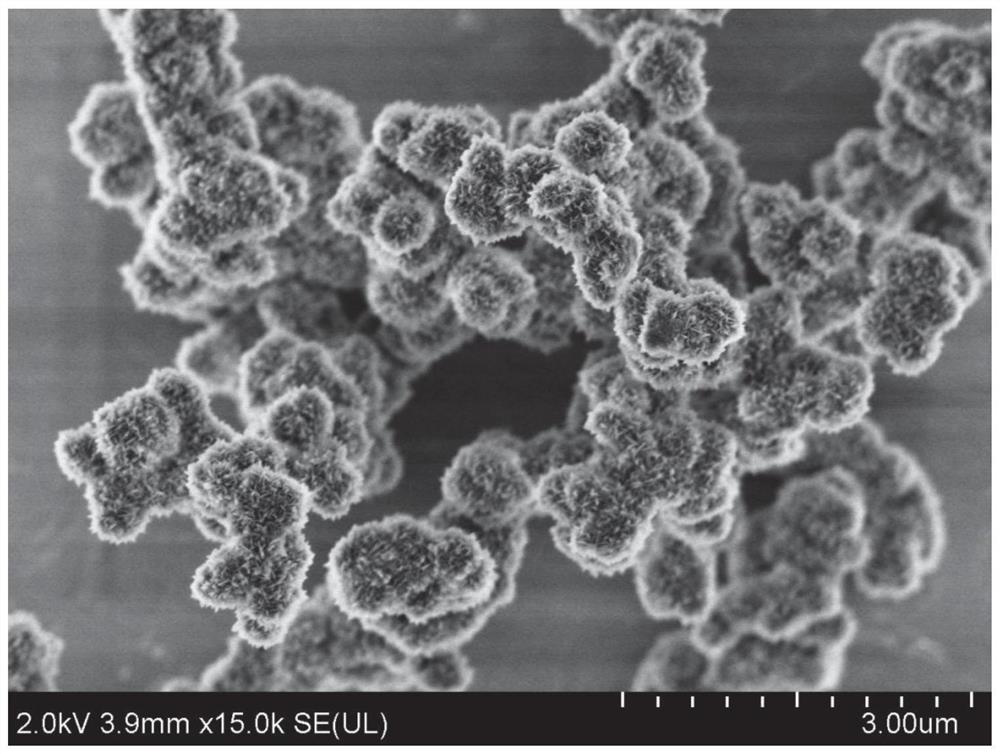

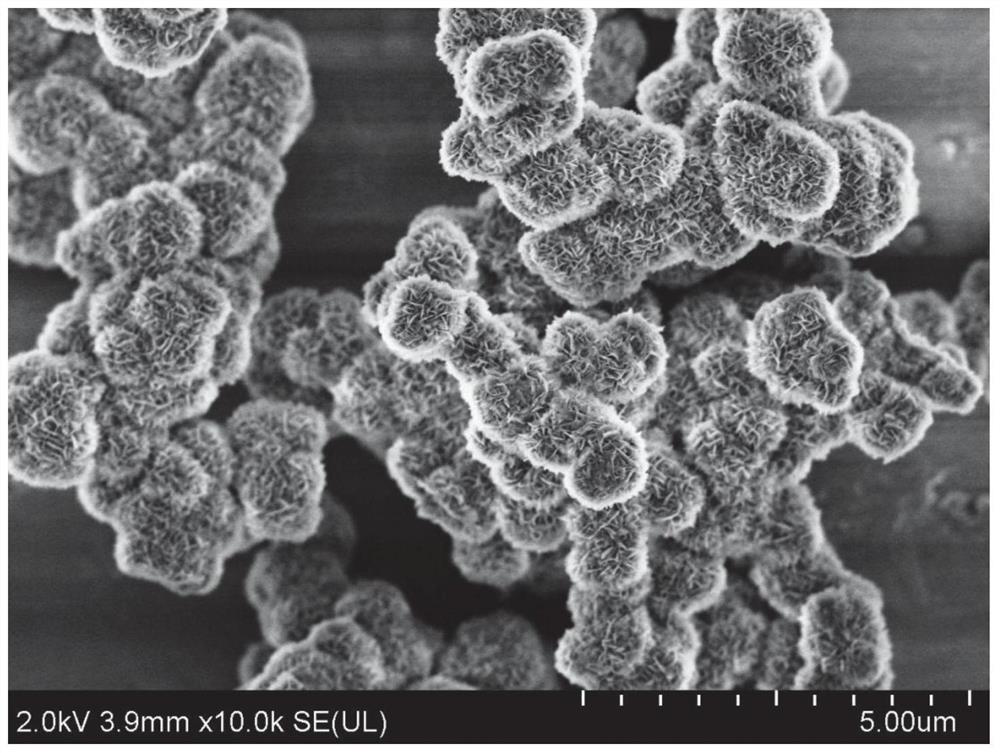

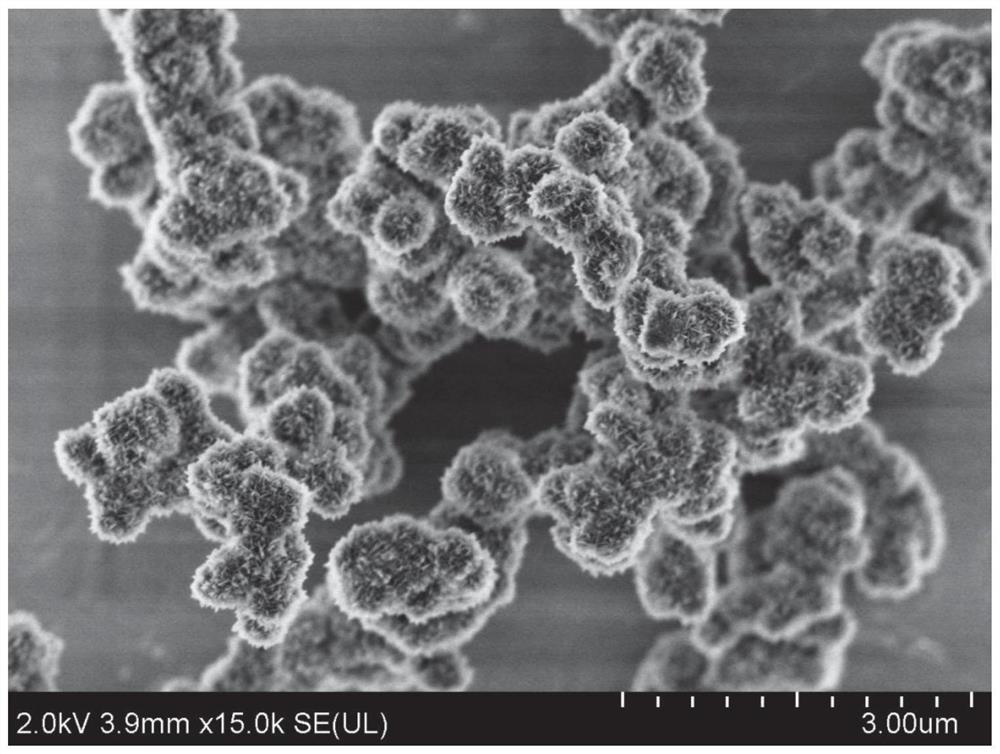

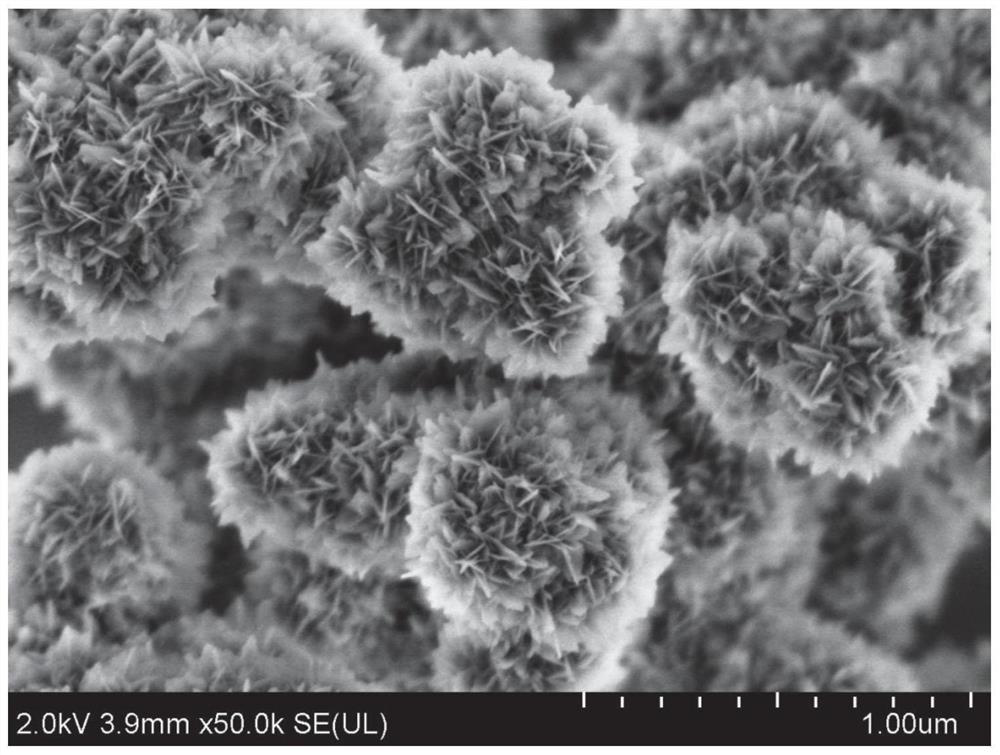

Three-dimensional layered chromium hydroxide monohydrate nanosphere and preparation method thereof

PendingCN114715937AUnique microstructureGood size controlNanotechnologyEnergy based wastewater treatmentHydration reactionStrong acids

The invention discloses a three-dimensional layered chromium hydroxide monohydrate nanosphere and a preparation method thereof. The preparation method comprises the following steps: preparing a neutral or alkaline aqueous solution containing a hexavalent chromium compound and a reducing agent as a reaction solution, carrying out a hydrothermal reaction on the reaction solution at 200-280 DEG C, and carrying out post-treatment to obtain the three-dimensional layered chromium hydroxide monohydrate nanospheres. The three-dimensional layered chromium hydroxide monohydrate nanosphere has a unique microstructure, controllable size and strong acid and alkali resistance, has a large specific surface area and abundant surface hydroxyl groups, has the advantages of good dispersibility, high stability, good filtration performance and the like, has a wide application prospect, is simple in preparation process and easy to implement, and is suitable for industrial production. The cost is low, the controllability is good, and the requirements of industrial production can be well met.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

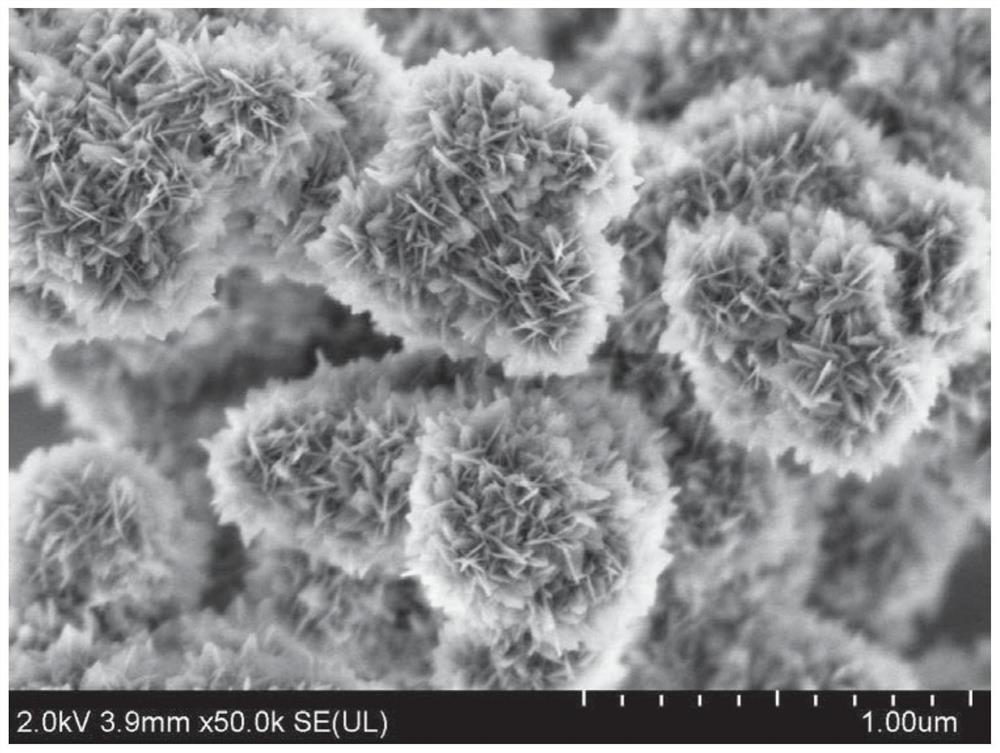

Nano chromium sesquioxide and preparation method thereof

PendingCN114715939AUniform and controllable particle sizeUniform and controllable shapeChromium trioxideHydration reactionChromium Hexavalent Compound

The invention discloses nano chromium sesquioxide and a preparation method thereof. The preparation method comprises the following steps: preparing a neutral or alkaline aqueous solution containing a hexavalent chromium compound and a reducing agent as a reaction solution, carrying out a hydrothermal reaction on the reaction solution at 200-280 DEG C, and carrying out post-treatment to obtain the three-dimensional layered chromium hydroxide monohydrate nanospheres, and the three-dimensional layered chromium hydroxide monohydrate nanospheres are roasted at the temperature of 800 DEG C to 1000 DEG C, and the nano chromium sesquioxide is obtained. Compared with the prior art, the preparation process of the nano chromium sesquioxide is simple and controllable, chromium loss can be effectively avoided, no chromium-containing waste residue is discharged, the obtained nano chromium sesquioxide is uniform and controllable in particle size and morphology, and the nano chromium sesquioxide has wide application prospects in multiple fields, such as preparation of high-end pigments, grinding materials and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Chrome complex dye as well as preparation method and applications thereof

ActiveCN101665628BGood weather resistanceSolve the problem of poor weather fastnessNon-macromolecular organic additionInksSolubilityWeather resistance

Owner:DALIAN UNIV OF TECH +1

Process for preparing sprayed chromic oxide

InactiveCN104418384AShort calcination timeReduce energy consumptionChromium trioxideReaction temperatureChromium Hexavalent Compound

The invention discloses a process for preparing sprayed chromic oxide, belongs to the field of inorganic material preparation, and particularly relates to a process for preparing sprayed chromic oxide by employing a hydrothermal process. The process is characterized by comprising the following steps: with a hexavalent chromium compound as an oxidant, a small molecular alcohol or aldehyde as a reducing agent, and a mixture of positive ions such as polyatomic acid and long-chain alkyl ammonium salt as a surfactant, mixing the raw materials according to the condition that the molar ratio (mol / mol) of the reducing agent to the oxidant is 0.1 to 5, the molar ratio (mol / mol) of the surfactant to the oxidant is 0.001-0.5, and the molar ratio (mol / mol) of the polyatomic acid to the long-chain alkyl ammonium salt in the surfactant is 0-100; keeping the reaction temperature constant at 100-300 DEG C in general under an initial hydrothermal condition; reacting for a period of time, wherein the general reaction time is shorter than 120 minutes; washing, drying and burning the obtained sediment, so as to obtain spherical micron grade sprayed chromic oxide, wherein the burning temperature is 600-1200 DEG C in general; and the burning time is shorter than 2 hours in general. The method is simple in process and low in energy consumption, and has promotional value; and the burning time is much shorter than that of an existing patent.

Owner:HEBEI UNIV OF ENG

Carbon embedding treatment for chronium-containing solid waste

InactiveCN100518968CAchieve harmless treatmentContinuous productionSolid waste disposalChromium CompoundsSlag

A carbon-burying treatment method for chromium-containing solid waste. The chromium-containing solid waste is crushed to a particle size of ≤3mm and spread in a sagger. The thickness of the chromium-containing solid waste laid is 0.1 to 1m, and a blanket is laid on it. Layer of fixed carbon (charcoal or coke), the fixed carbon content is 0.5 to 10% of the chromium-containing solid waste in terms of weight percentage. Place the sagger on the platform trolley, drive it into the heating furnace, keep it warm at 1000-1350°C for 30-180 minutes under normal pressure, then drive the trolley out and cool it to room temperature. Due to the carbon burial treatment process, this method can convert all hexavalent chromium compounds into trivalent chromium compounds, which can remove almost all hexavalent chromium in chromium-containing solid waste and achieve harmless treatment of chromium slag. This method can be used for continuous production operations, with large processing capacity, and there is no recovery of hexavalent chromium after detoxification.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com