Method for calcium-free calcination production of sodium chromate and chromium-containing cast iron as co-product

A calcium-free roasting and sodium chromate technology, applied in the direction of chromate/dichromate, etc., can solve the problems of large energy loss and low roasting efficiency, and achieve product quality improvement, comprehensive utilization rate improvement, and production capacity increase big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The following is an example of the production of sodium chromate and co-production of chromium-containing cast iron by oxygen-enriched roasting, wherein the composition of the chromium ore used is as shown in table 1

[0019] The chromite composition that adopts in the embodiment 1 of table 1

[0020] Cr 2 o 3

FeO

MgO

Al 2 o 3

SiO 2

CaO

V 2 o 5

Na 2 o

44.01%

25.64%

9.87%

16.23%

2.09%

1.0%

0.16%

0.01%

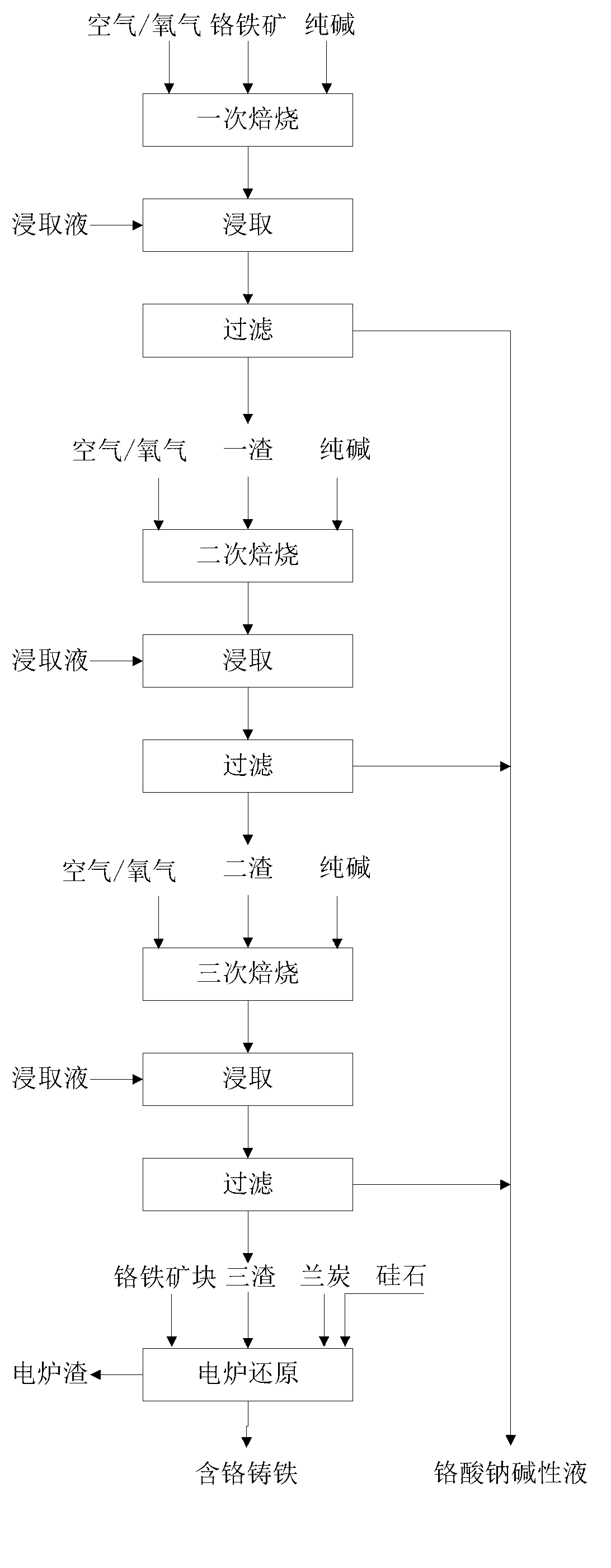

[0021] see figure 1 The process of producing sodium chromate and co-producing chromium-containing cast iron by oxygen-enriched roasting includes:

[0022] A roasting process: 3.4 tons of chromite (ground to 200 mesh with a pass rate greater than 95%) and 1 ton of soda ash (Na 2 CO 3 content: 98.62%) and mixed evenly; put it into a rotary kiln for roasting at a temperature of 1100-1200 ° C, and feed 0.42 tons of oxygen, and the material stays in the kiln for 150 minutes withou...

Embodiment 2

[0037] This example is an example of the production of sodium chromate and the co-production of chromium-containing cast iron by the air roasting process, wherein the composition of the chromium ore used is shown in Table 5.

[0038] The chemical composition of chromite in table 5 embodiment 2

[0039] Cr 2 o 3

FeO

MgO

Al 2 o 3

SiO 2

CaO

V 2 o 5

Na 2 o

44.5%

26.2%

11.2%

14.4%

2.6%

0.7%

0.16%

0.01%

[0040] The process of air roasting to produce sodium chromate and co-production of chromium-containing cast iron includes:

[0041] A roasting process: 3.4 tons of chromite (ground to 200 mesh with a pass rate greater than 95%) and 1.2 tons of soda ash (Na 2 CO 3 content: 98.62%) and mix evenly; put it into a rotary kiln for roasting at a temperature of 1100-1200 ℃, and let in air so that the material does not form a wall, and clinker is obtained. The clinker processing method obtained...

Embodiment 3

[0056] Comprehensive utilization of the three slags.

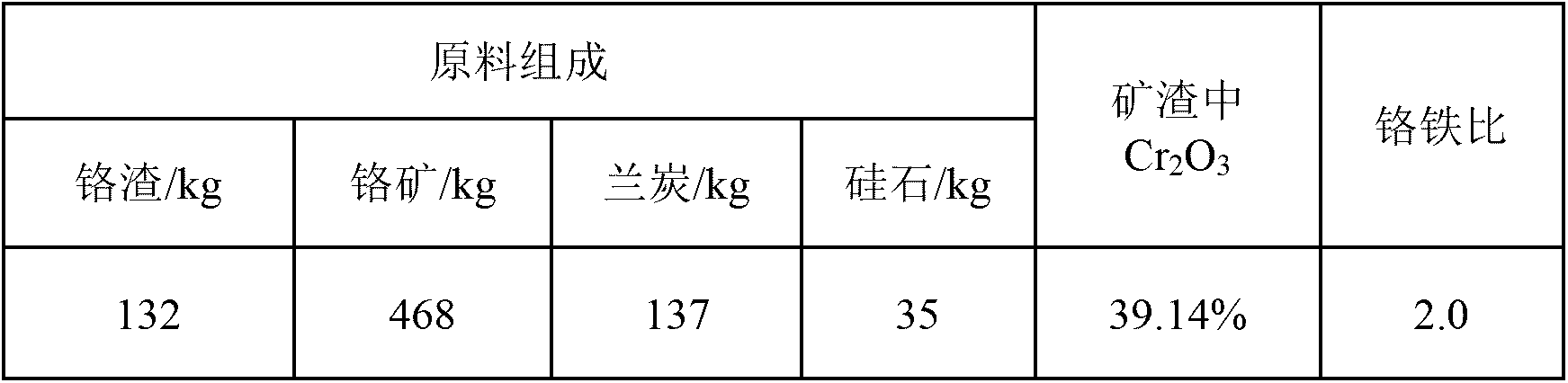

[0057] Mix the calcium-free chromium slag with the chromite block at a ratio of 1:3.55, and then add semi-coke, silica, etc. into the reduction furnace for smelting. The ratio of raw materials is shown in Table 9:

[0058] Table 9 uses the three-stage roasting filter slag to carry out the batching ratio of high-carbon ferrochrome smelting

[0059]

[0060] A total of 21 batches of products were obtained in this group of tests, and about 20 batches of materials were fed into each batch, and an average of 4.9 tons of high-carbon ferrochromium was obtained per batch, and 6.0 tons of electric furnace slag was produced.

[0061] Wherein, the chrome ore composition used is as shown in table 10:

[0062] Table 10 Chemical composition of chromite for smelting chromium-containing cast iron test

[0063] Cr 2 o 3

[0064] Among them, the blue carbon composition includes 80% C, 14% ash, 5% volatile matter, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com