Spray chrome oxide preparation method

A technology of chromium oxide and oxidant, which is applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of long time consumption, high energy consumption, complicated process, etc., and achieve the effect of shortening calcination time, reducing energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

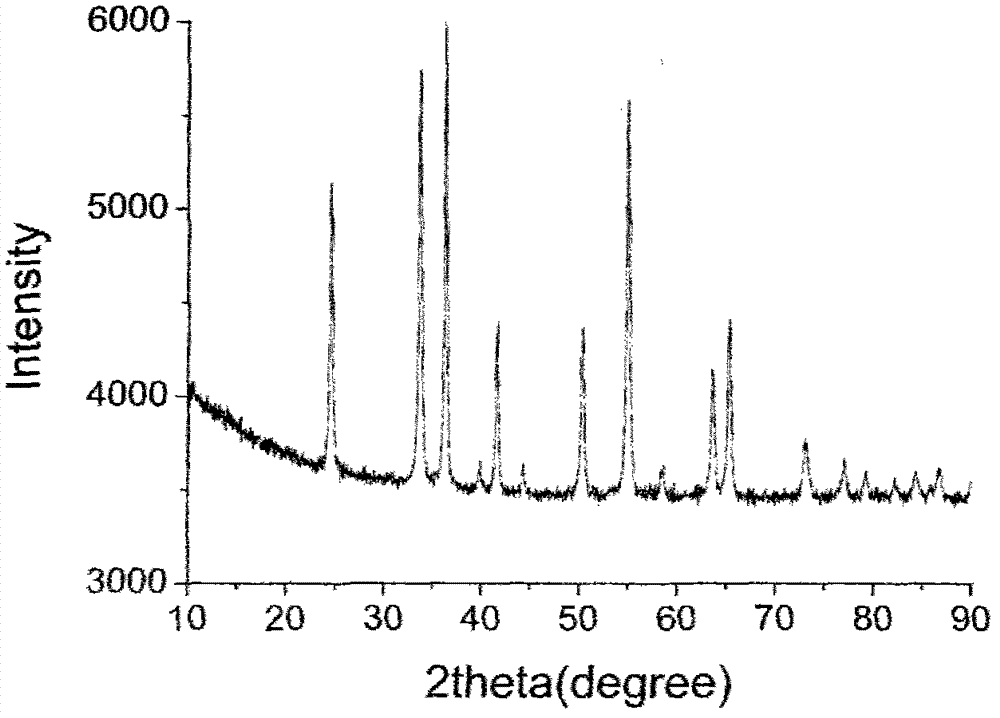

Image

Examples

Embodiment 1

[0021] 2~4g K 2 CrO 4 , 0.3 ~ 1g methanol, 0.05 ~ 0.7g of a certain polyol 1 # mixed with 30g of water, react in a closed system, the temperature is 180 ~ 240 ℃, the reaction time is 60min; after the reaction, take out the obtained precipitate, after washing, Dry at 110°C, and then calcined at 1000°C for 2 hours to obtain nearly spherical micron-scale sprayed chromium oxide.

Embodiment 2

[0023] 2~4g K 2 CrO 4 , 0.5~1.2g formaldehyde, 0.02~0.6g certain polyol 2# mixed with 30g water, react in a closed system, the temperature is 180~240°C, and the reaction time is 60min; after the reaction, take out the obtained precipitate and wash it , Dry at 110°C, and then calcined at 1000°C for 2 hours to obtain micron-sized spray-coated chromium oxide that is approximately spherical.

Embodiment 3

[0025] 2~4g CrO 3 , 0.3-1g methanol, 0.04-0.9g a polybasic acid 3# and 30g water are mixed evenly, react in a closed system, the temperature is 180-240°C, and the reaction time is 60min; Dry at 110°C, and then calcined at 1000°C for 2 hours to obtain nearly spherical micron-scale sprayed chromium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com