Chrome complex dye as well as preparation method and applications thereof

A technology of chromium complexing and dyes, applied in dyeing methods, azo dyes, organic dyes, etc., can solve the problems of poor weather fastness of inkjet inks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

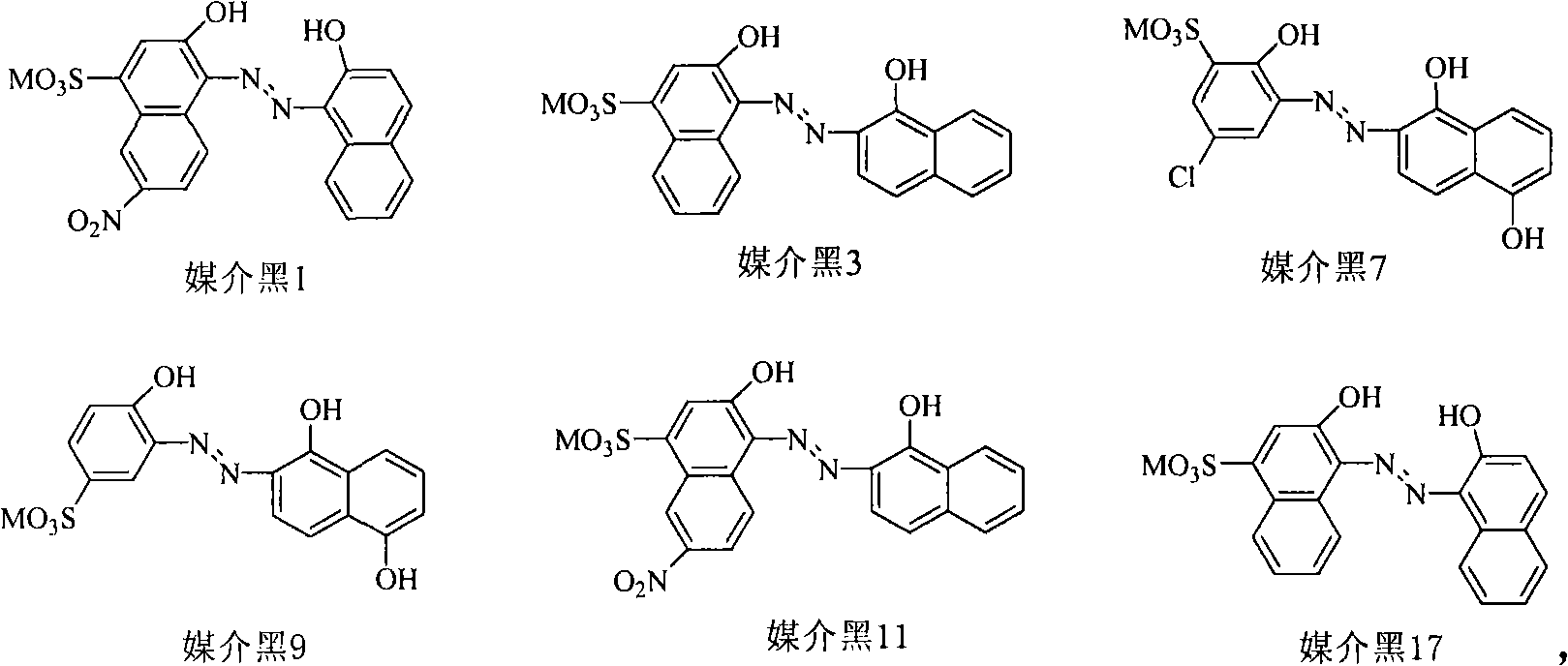

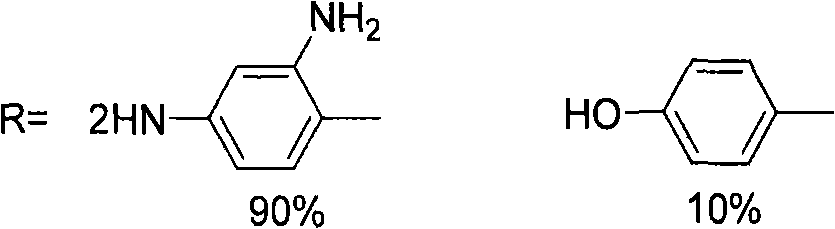

[0059] The preparation method of the chromium complex dye of the present invention is as follows.

[0060] Under stirring, add the mordant black dye and the hexavalent chromium compound or the mixture of the hexavalent chromium compound and the trivalent chromium compound used as an oxidative complexing reagent in the ratio of 1: (0.5-2) into the reaction vessel, and Water used as a solvent is added. Raise the temperature in the reaction vessel to 60-150℃ to oxidize the dye and the hexavalent chromium compound, and at the same time, the dye is complexed with the trivalent chromium chromium formed by the reduction. During the reaction, the pH value of the system remains 1-6, and the reaction time For 0.5-8 hours.

[0061] The molar ratio of dye: oxidizing complexing agent is preferably 1: (0.8-1.5). The reaction temperature is preferably 60-120°C, more preferably 70-110°C, still more preferably 80-102°C. The reaction time is preferably 1-8 hours, more preferably 2-6 hours, still ...

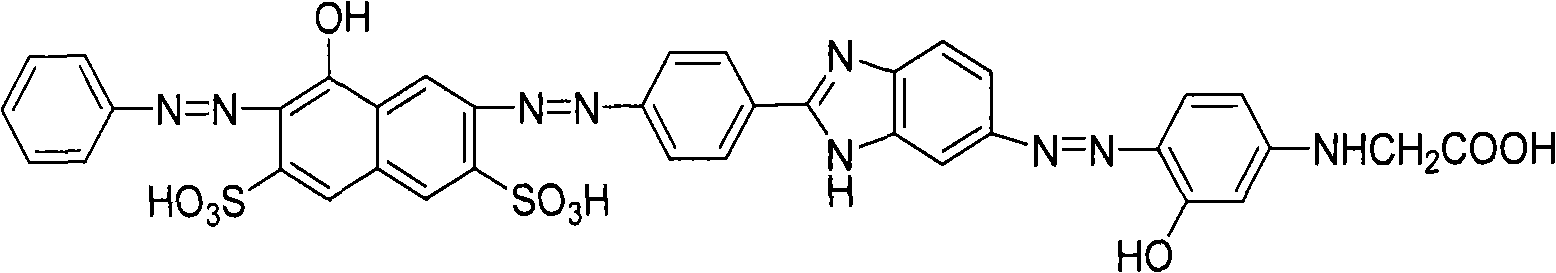

Embodiment 1

[0086] Two-step method: Add 150.0 parts of mordant black 7 dye to a 2L three-necked flask, add 1L of deionized water, heat up to 70~80℃, slowly add 53.6 parts of sodium dichromate, keep it boiling for 6h, and control the pH at 6.0 , To obtain a black thick slurry, reduce the temperature to 70 ~ 80 ℃, slowly add 54.02 parts of tartaric acid. After reacting for 5 hours under boiling, the pH is controlled at 3.0, the reactant becomes a solution, cooled, and the pH is adjusted to 8.5-8.6. The high-pressure reverse osmosis membrane is desalted to obtain a 1:1 chromium complex dye 7-1 of mordant black 7. According to HPLC-ESI-MS analysis, the product mainly contains compound dye 7-1-a and compound dye 7-1-b. Through HPLC preparation and separation, pure compounds of compound dye 7-1-a and compound dye 7-1-b were obtained respectively. The molecular molar mass of the compound dye 7-1-a should be 676.9 (M' in Na), and the electrospray mass spectrometry (API-ES) detection, in the negat...

Embodiment 2

[0090] Substituting 54.0 parts of tartaric acid in Example 1 with 32.0 parts of oxalic acid, and other conditions unchanged, a 1:1 chromium complex dye dye 7-2 of mordant black 7 was obtained. According to HPLC-ESI-MS analysis, it mainly contains compound dye 7-2-a and compound dye 7-2-b. The pure compounds of dye 7-2-a and compound dye 7-2-b were obtained by HPLC preparation and separation. The molecular molar mass of the compound dye 7-2-a should be 617.8 (M' is calculated as Na), and the electrospray mass spectrometry (API-ES) detection. In the negative mode, the electrospray mass spectrometry has a base peak with a mass-to-charge ratio of 285.9, which is The two negative ion peaks of the dye (molecular mass [M-2Na] / 2) and the one negative ion peak ([M-Na]) with a mass-to-charge ratio of 594.8 all prove that the dye molecular weight M is 617.8; compound dye 7-2-b The molecular molar mass M should be 631.8 (M' in Na), and the electrospray mass spectrometry (API-ES) detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com