Nano chromium sesquioxide and preparation method thereof

A technology of chromium trioxide and chromium hydroxide, which is applied in the directions of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of wide particle size distribution, complex production process and poor morphology uniformity, etc., and achieve no chromium content. The effect of waste residue discharge, uniform and controllable morphology, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] An aspect of the embodiment of the present invention provides a preparation method of nano-chromium trioxide, comprising:

[0027] A neutral or alkaline aqueous solution containing a hexavalent chromium compound and a reducing agent is prepared as a reaction solution, and the reaction solution is subjected to a hydrothermal reaction at a temperature of 200 to 280 ° C, and then post-processing is performed to obtain a three-dimensional layered monohydrate Chromium hydroxide nanospheres;

[0028] The three-dimensional layered chromium hydroxide monohydrate nanospheres are calcined at 800-1000° C., and then cooled naturally to obtain nano-chromium trioxide.

[0029] Further, the concentration of the hexavalent chromium compound contained in the reaction solution is below the saturation concentration of the hexavalent chromium compound. Preferably, the concentration of the hexavalent chromium compound contained in the reaction solution is 1-2 mol / L.

[0030] Further, the ...

Embodiment 1

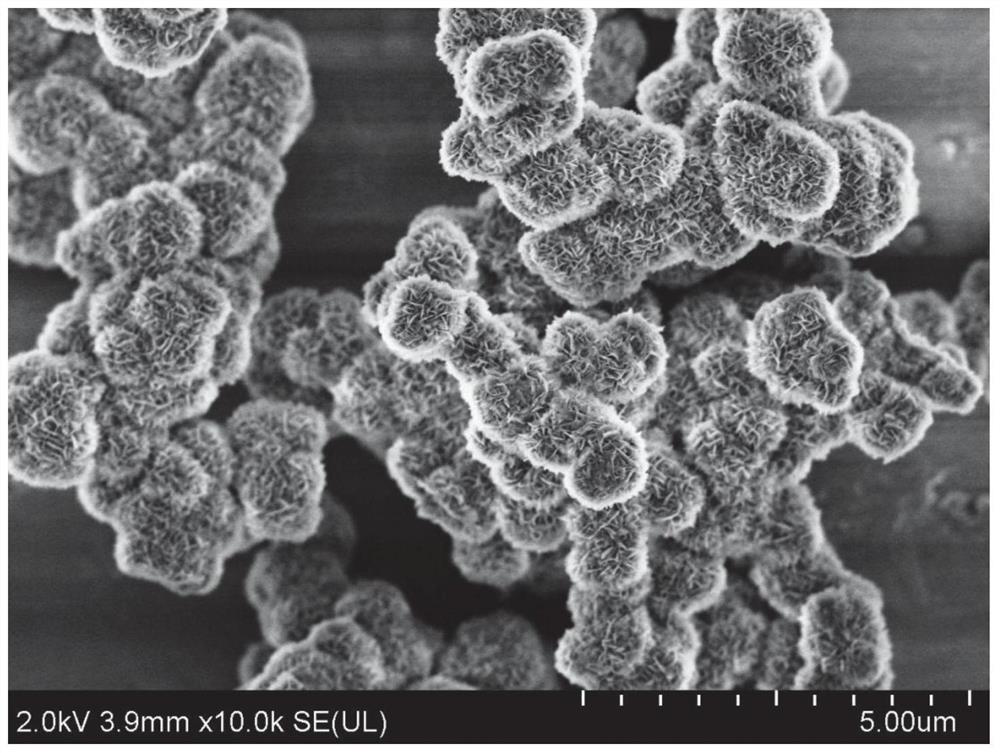

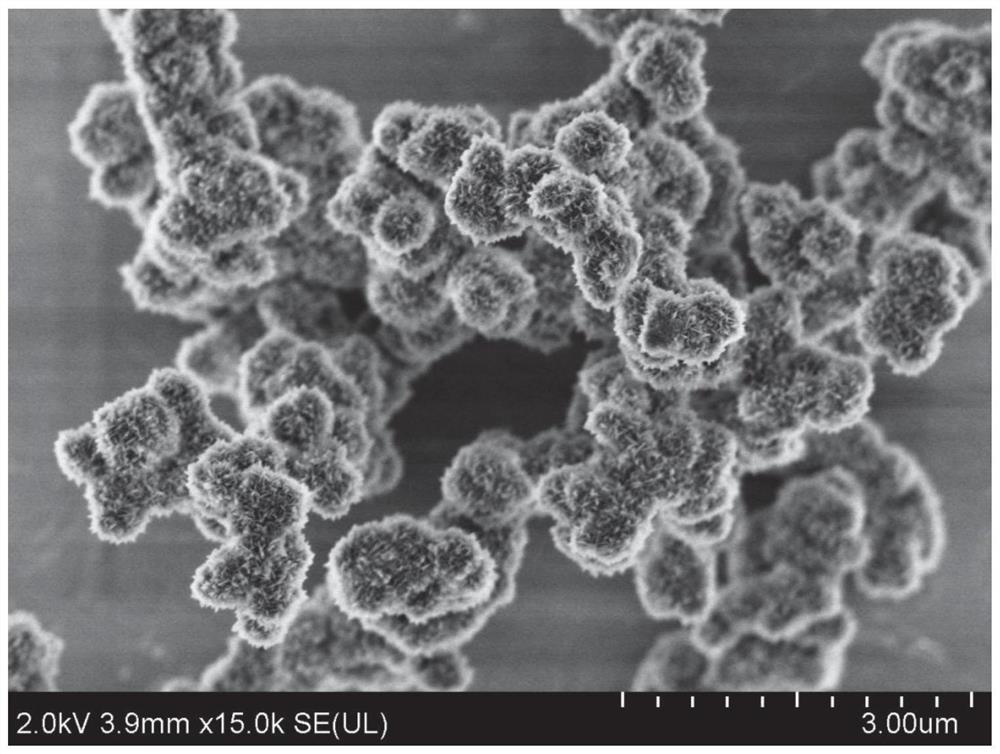

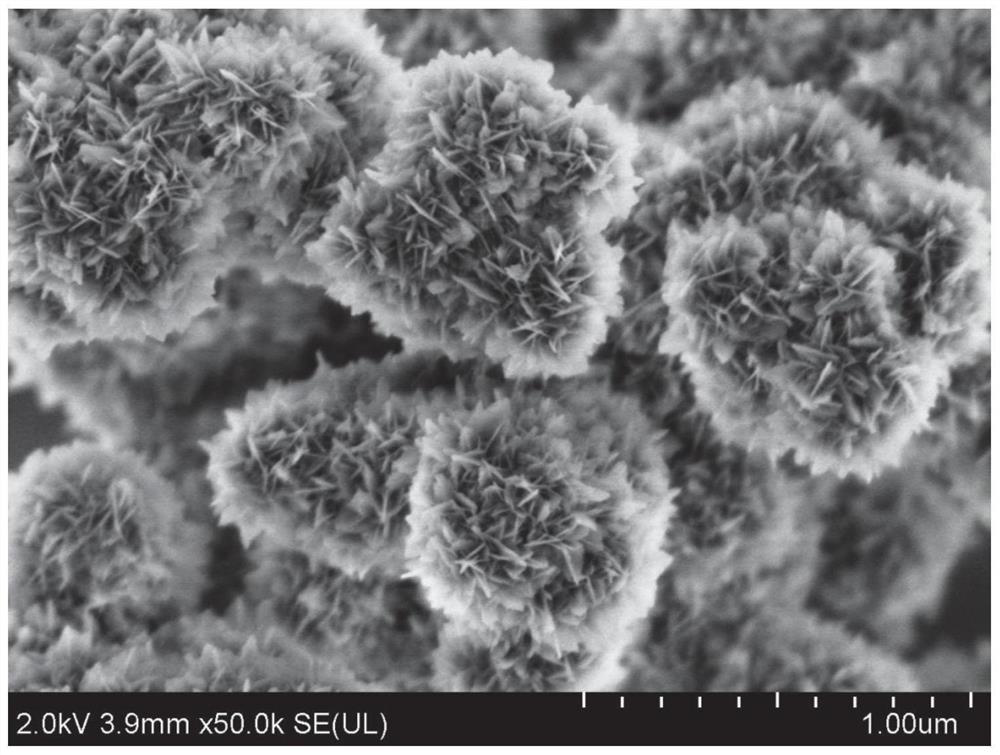

[0052] Example 1 25g sodium chromate, 5g sodium carbonate, 3g sodium hydroxide were added to a certain amount of water to configure a 100ml aqueous solution, then 2g citric acid was added, and the pH value of the solution was about 14 at this time; the configured solution was transferred to 150ml stainless steel high temperature reaction kettle, heated to 280℃, hydrothermal reaction for 12h. Then, the obtained slurry was cooled to room temperature naturally, and after suction filtration, it was fully washed with water until neutral, and vacuum-dried to obtain three-dimensional layered chromium hydroxide monohydrate nanospheres as an intermediate. Figure 1 to Figure 4 As shown, its XRD characterization pattern shows that the intermediate is chromium hydroxide monohydrate (such as Figure 5 shown). Afterwards, the obtained three-dimensional layered chromium hydroxide nanospheres were heated to 800°C at a heating rate of 2°C / min in the air, calcined at a constant temperature fo...

Embodiment 2

[0053] Example 2 25g potassium chromate, 10g potassium carbonate were added to a certain amount of water and configured into a 100ml aqueous solution, then 2g acetic acid was added, and the pH value of the solution was about 12 at this time; the configured solution was transferred to a 150ml stainless steel high temperature reactor, Heated to 260°C for hydrothermal reaction for 15h. Then, the obtained slurry is naturally cooled to room temperature, after suction filtration, fully washed with water until neutral, and freeze-dried to obtain three-dimensional layered chromium hydroxide monohydrate nanospheres. Afterwards, the obtained three-dimensional layered chromium hydroxide nanospheres were heated to 900°C at a heating rate of 5°C / min in air, calcined at a constant temperature for 2 hours, cooled naturally, washed and dried to obtain nano-chromium trioxide products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com