Three-dimensional layered chromium hydroxide monohydrate nanosphere and preparation method thereof

A chromium hydroxide and nanosphere technology, applied in the field of material science, to achieve the effects of good controllability, strong acid and alkali resistance, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

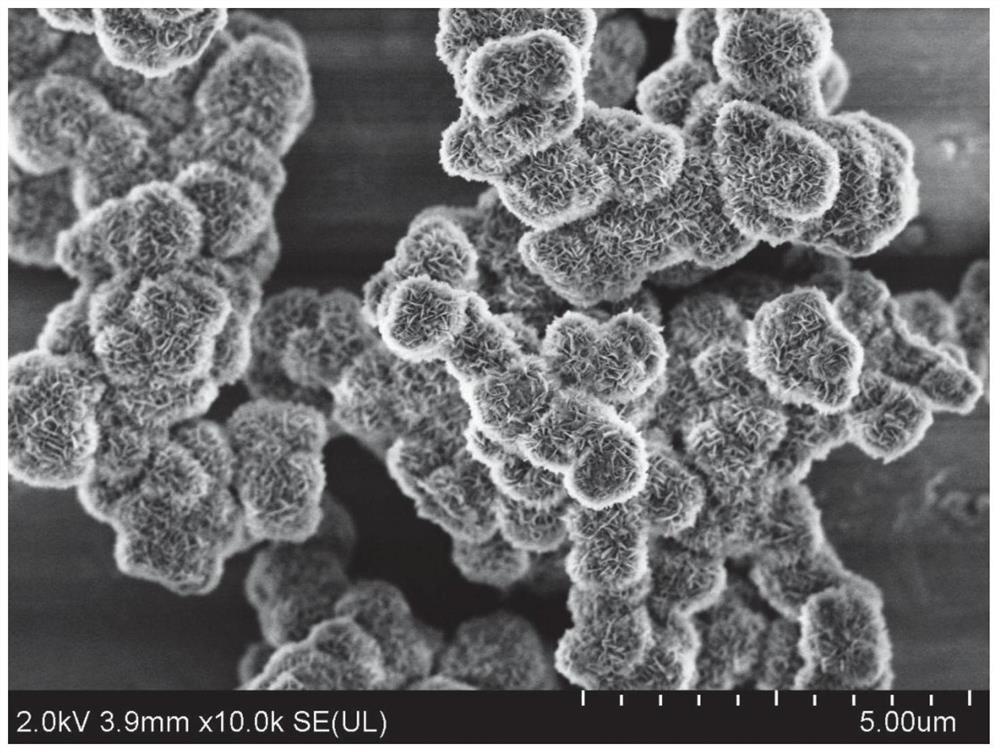

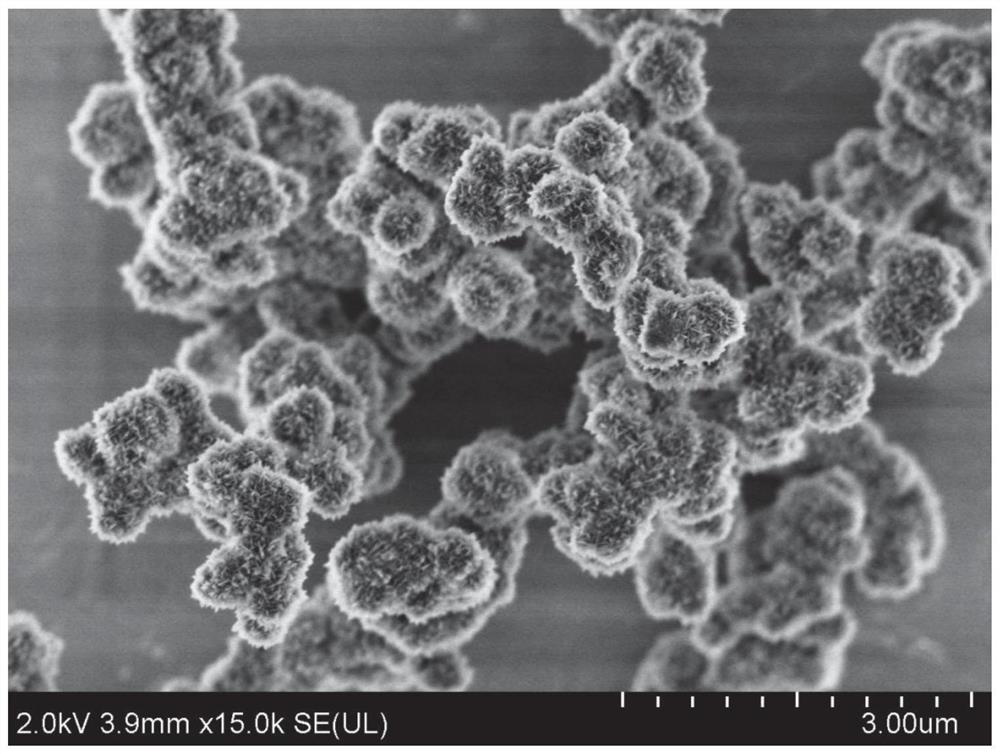

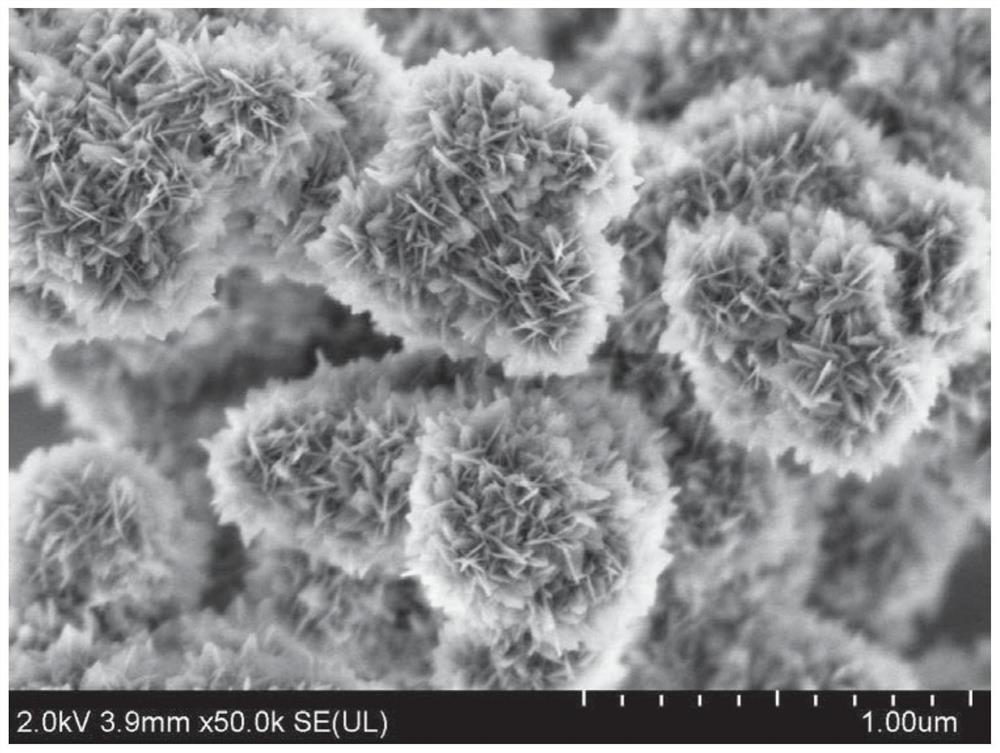

[0024] One aspect of the embodiments of the present invention provides a method for preparing three-dimensional layered chromium hydroxide monohydrate nanospheres, comprising: preparing a neutral or alkaline aqueous solution containing a hexavalent chromium compound and a reducing agent as a reaction solution, and making the The reaction solution is subjected to a hydrothermal reaction at a temperature of 200° C. to 280° C., and is then subjected to post-treatment to obtain three-dimensional layered chromium hydroxide monohydrate nanospheres.

[0025] Further, the concentration of the hexavalent chromium compound contained in the reaction solution is below the saturation concentration of the hexavalent chromium compound. Preferably, the concentration of the hexavalent chromium compound contained in the reaction solution is 1-2 mol / L.

[0026] Further, the molar ratio of the hexavalent chromium compound and the reducing agent in the reaction solution is 1:1-1.5.

[0027] Furth...

Embodiment 1

[0044] Example 1: 25g sodium chromate, 5g sodium carbonate, 3g sodium hydroxide were added to a certain amount of water to configure a 100ml aqueous solution, then 2g citric acid was added, and the pH value of the solution was about 14 at this time; the configured solution was transferred. to a 150ml stainless steel autoclave, heated to 280°C, and reacted for 12h. Then, the obtained slurry was naturally cooled to room temperature, and after suction filtration, it was fully washed with water until neutral, and then freeze-dried to obtain a product, namely three-dimensional layered chromium hydroxide monohydrate nanospheres, whose appearance is as follows Figure 1-Figure 4 As shown, the XRD characterization results are as follows Figure 5 shown, indicating that the resulting product consists of chromium hydroxide monohydrate.

Embodiment 2

[0045] Embodiment 2: 25g potassium chromate, 10g potassium carbonate are added to a certain amount of water to configure into a 100ml aqueous solution, then 2g acetic acid is added, and the pH value of the solution is about 12 at this time; The configured solution is transferred to a 150ml stainless steel autoclave , heated to 260°C, and reacted for 15h. Then, the obtained slurry is naturally cooled to room temperature, after suction filtration, fully washed with water until neutral, and freeze-dried to obtain a product, namely three-dimensional layered chromium hydroxide monohydrate nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com