A kind of preparation method of non-spherical silicon dioxide particle

A silicon dioxide, non-spherical technology, applied in the direction of silicon dioxide, silicon oxide, etc., to achieve superior application value, mild preparation conditions, and unique shape effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

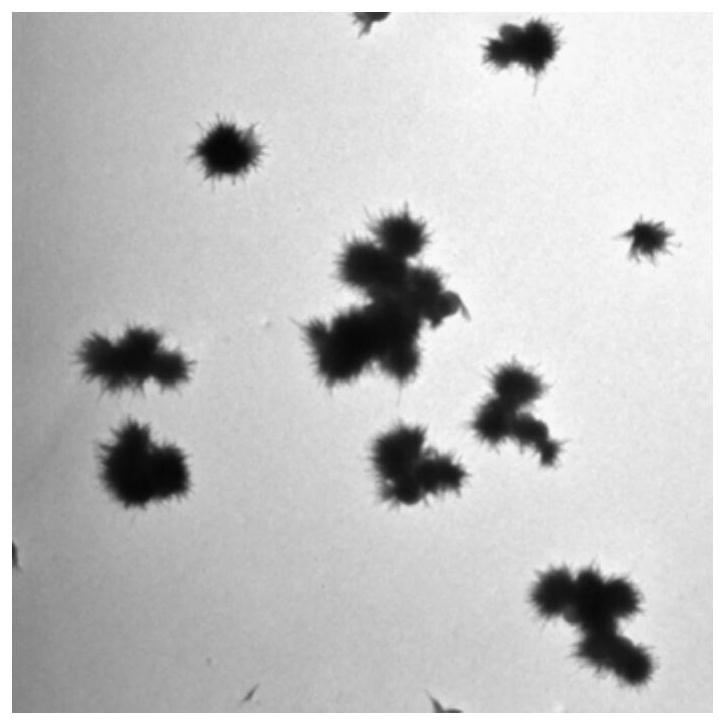

[0028] In the 13.3mL ethanol system, add 6.6mL water, then add 1.0mL0.4mol / L tetrabutylammonium bromide solution and 1.5mL concentrated ammonia water (wt.25%, in the reaction system The final concentration is 1.0mol / L), after the reaction temperature is stabilized to 30°C, 0.4mL tetraethyl orthosilicate (final concentration in the reaction system is 0.09mol / L) is finally added, stirred for 8 hours, and centrifuged to remove The supernatant (4000rpm, 15min) was washed twice with water, and the particles were dried at 70°C to obtain "sea urchin-like" silica particles.

Embodiment 2

[0030] In 10.0mL ethanol system, add 10.0mL water, then add 1.0mL0.4mol / L tetramethylammonium bromide solution and 1.5mL concentrated ammonia water (wt.25%, in the reaction system The final concentration is 1.0mol / L), after the reaction temperature is stabilized to 30°C, 0.4mL tetraethyl orthosilicate (final concentration in the reaction system is 0.09mol / L) is finally added, stirred for 8 hours, and centrifuged to remove The supernatant (4000rpm, 15min) was washed twice with water, and the particles were dried at 70°C to obtain "bundle-like" silica particles.

Embodiment 3

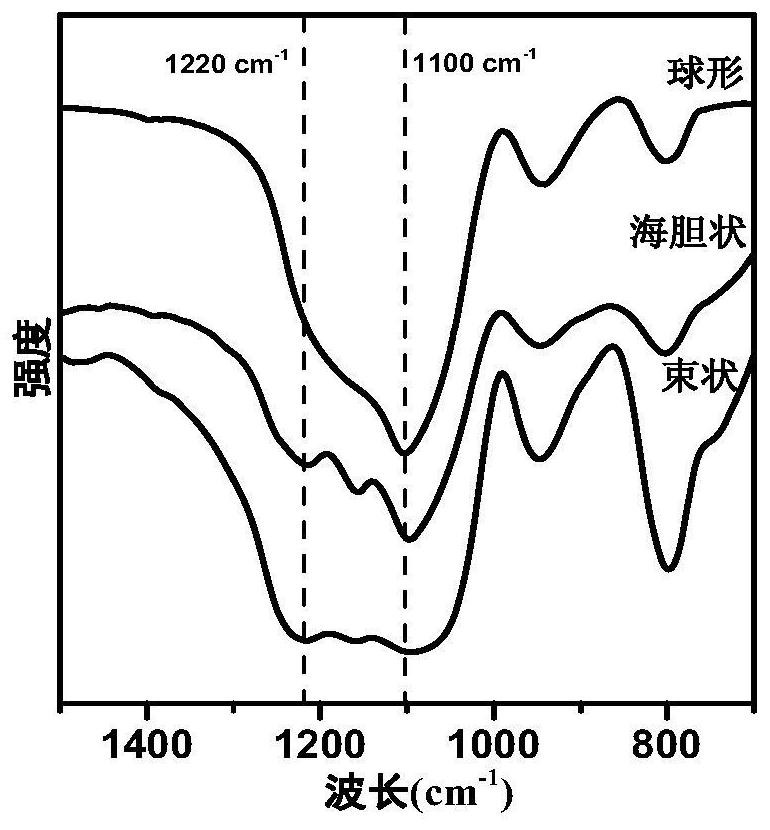

[0032] Using an infrared characteristic spectrometer, the spherical silica particles prepared by the traditional sol-gel method, the "sea urchin shape" prepared in Example 1, and the "beam-shaped" silica particles prepared in Example 2 were respectively measured at 1500-700cm -1 The infrared characteristic spectrum of the region. As can be seen from the figure, compared with the spherical silica particles prepared by the traditional sol-gel method, the "sea urchin-like" and "beam-like" silica particles prepared by the present invention have a corresponding Si-O-Si characteristic peak. 1300-1000cm -1 In the region, different peak shapes are shown: compared with the infrared characteristic peaks of spherical silica particles, "sea urchin-like" silica particles and "beam-like" silica particles have broader shoulders, and, in Si- O-Si characteristic peak 1100cm -1 , the "sea urchin-like" silica particles and the "beam-like" silica particles all have red shifts in varying degrees...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com