a co/zro 2 /c Electromagnetic wave absorbing material and its preparation method and application

A technology for absorbing materials and electromagnetic waves, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of inability to provide electrical and magnetic losses, difficult to obtain electromagnetic wave absorption performance, and difficult to achieve broadband absorption, etc., to achieve beneficial electromagnetic waves. The effect of absorption performance, excellent impedance matching performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] Again, the present invention discloses a Co / ZrO 2 The preparation method of / C electromagnetic wave absorbing material comprises the steps:

[0052] (1) Mix zirconium source, organic ligand and acetic acid evenly in an organic solvent, and react at 100-400°C for 2-30 hours under airtight conditions. After the reaction is completed, the product is washed and dried to obtain MOF, and then The MOF is dispersed into the cobalt source solution to obtain a composite of MOF.

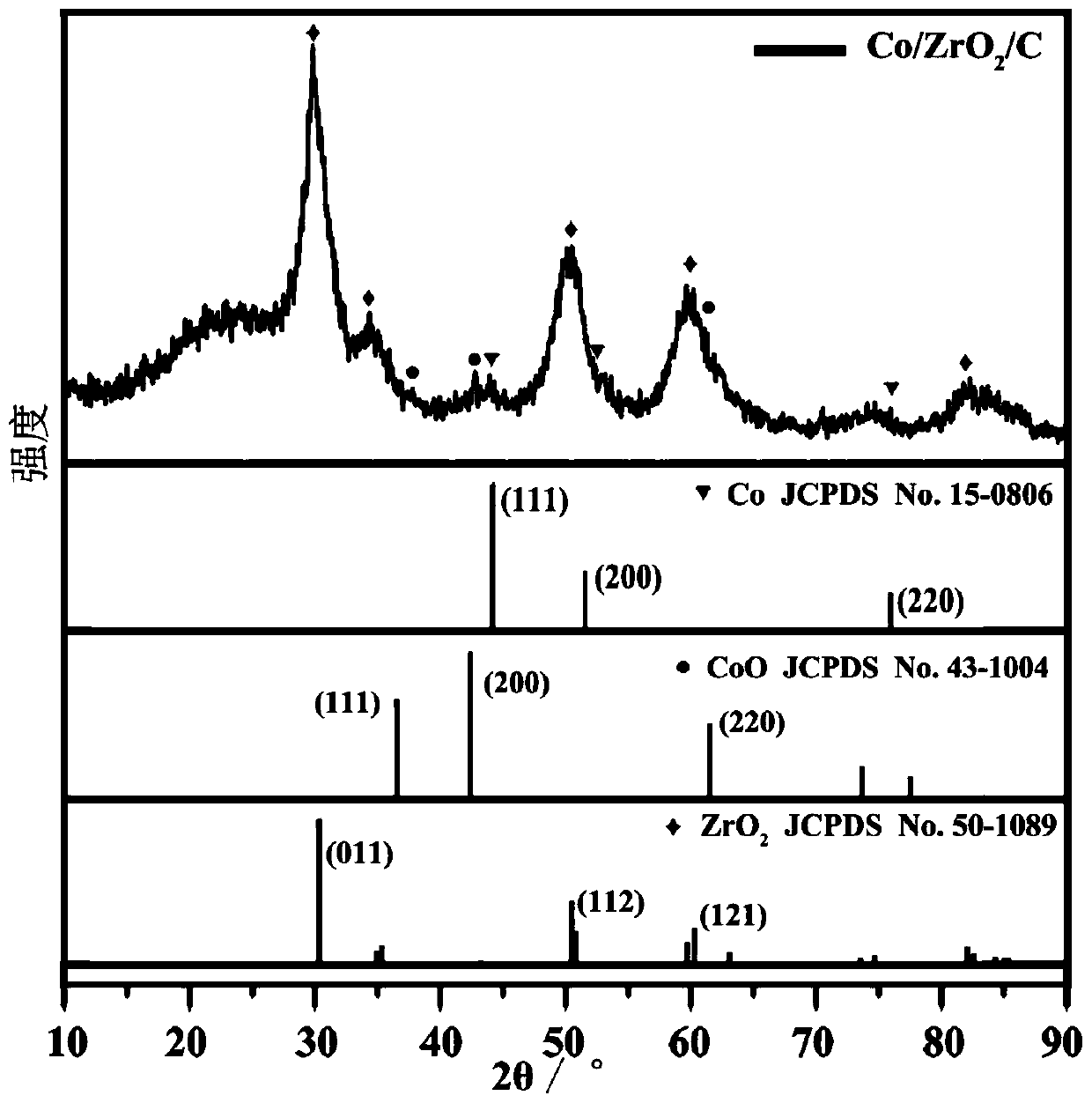

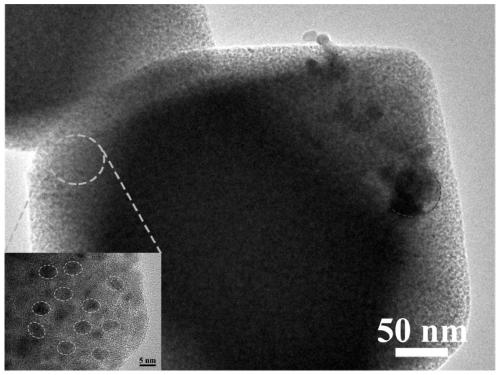

[0053] (2) Calcining the compound obtained in step (1) under a protective atmosphere, reducing the cobalt ions in the cobalt source to simple cobalt, and decomposing the MOF into ZrO 2 and carbon, that is, Co / ZrO 2 / C.

[0054] As a further technical solution, in step (1), the cobalt source includes any one of cobalt nitrate, cobalt chloride and cobalt sulfate.

[0055] As a further technical solution, in step (1), the zirconium source includes any one of zirconium tetrachloride and zirconium oxychlor...

Embodiment 1

[0067] A Co / ZrO 2 The preparation method of / C electromagnetic wave absorbing material comprises the steps:

[0068] (1) Add 5mL of acetic acid into 100mL of DMF, then dissolve 2.5mmol of zirconium tetrachloride and 2.5mmol of terephthalic acid in the above solution, and obtain a homogeneous transparent solution after vigorous stirring. After completion, the product is washed and dried to obtain a MOF precursor.

[0069] (2) Put the above precursor in 2mol / L cobalt nitrate solution, vacuum treatment (relative vacuum degree is -0.1MPa) for 30min, put it in the natural environment for 24h, then wash and dry to obtain the composite cobalt source MOF precursors.

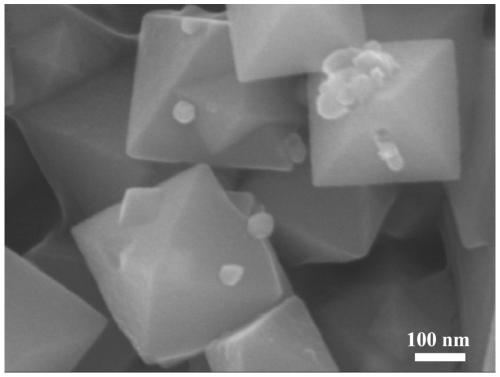

[0070] (3) Put the MOF precursor treated in step (2) in a closed tube furnace, and in a nitrogen atmosphere, keep it at 700°C for 2h for high-temperature calcination to obtain Co / ZrO 2 / C Electromagnetic wave absorbing material.

Embodiment 2

[0072] A Co / ZrO 2 The preparation method of / C electromagnetic wave absorbing material comprises the steps:

[0073] (1) Add 8mL of acetic acid to 100mL of DMF, then dissolve 3mmol of zirconium oxychloride and 2mmol of amino-terephthalic acid in the above solution, and obtain a homogeneous transparent solution after vigorous stirring, and keep it in a closed space at 300°C for 15h, and the reaction is complete Afterwards, the product is washed and dried to obtain a MOF precursor.

[0074] (2) Put the above precursor in 2.5mol / L cobalt chloride solution, vacuum treatment (relative vacuum degree is -0.1MPa) for 40min, then place it in the natural environment for 20h, then wash and dry to obtain composite cobalt The MOF precursor after the source.

[0075] (3) Put the MOF precursor treated in step (2) in a closed tube furnace, and in a nitrogen atmosphere, keep it at 650°C for 3h for high-temperature calcination to obtain Co / ZrO 2 / C Electromagnetic wave absorbing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorption bandwidth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com