Surface treatment method of nickel metal strip for lithium-ion battery negative electrode ear

A lithium-ion battery and surface treatment technology, applied in battery pack parts, metal material coating process, circuits, etc., can solve the problems of complex battery manufacturing process, increased process, poor solderability, etc., and achieve excellent electrolyte resistance performance. , Good soldering performance, the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

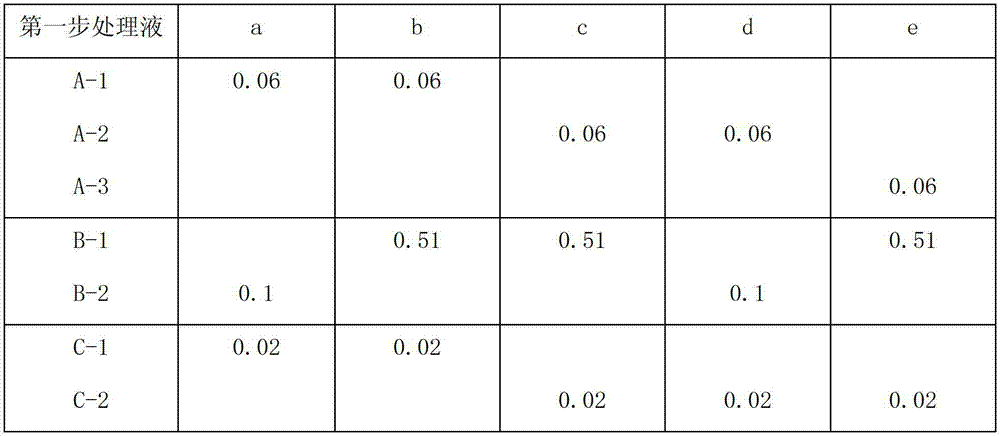

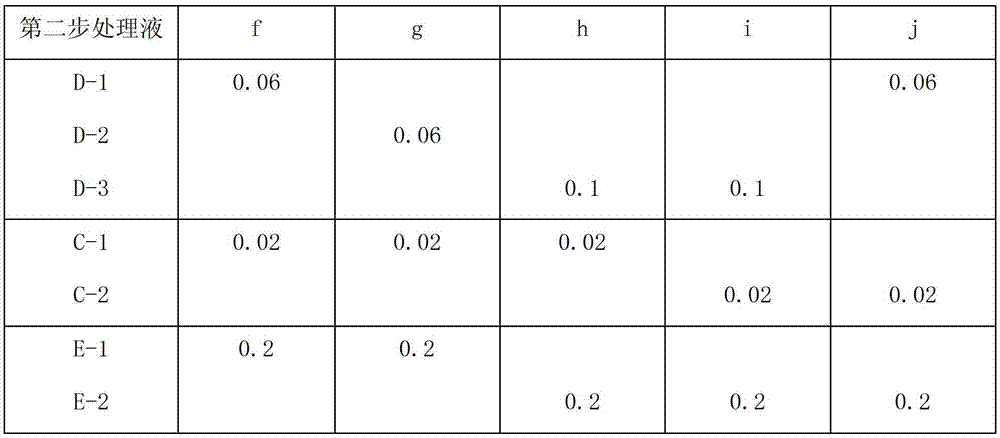

Embodiment 1

[0061] The preparation of treatment liquid: water or deionized water is solvent, and the first step treatment liquid is a, and the second step treatment liquid is f;

[0062] Approach:

[0063] (1) Remove the grease on the surface of the nickel strip and clean it with tap water;

[0064] (2) Immerse the nickel strip treated in (1) in the first step treatment solution at 40°C for 6 minutes, and clean it with tap water;

[0065] (3) Immerse the nickel strip treated in (2) in the second-step treatment solution at 40°C for 8 minutes, and clean it with tap water;

[0066] (4) The nickel strip treated in (3) is heated and dried at 80°C.

Embodiment 2

[0068] The preparation of treatment liquid: the first step treatment liquid is b, and the second step treatment liquid is g;

[0069] Approach:

[0070] (1) Remove the grease on the surface of the nickel strip and clean it with tap water;

[0071] (2) Immerse the nickel strip treated in (1) in the first step treatment solution at 40°C for 6 minutes, and clean it with tap water;

[0072] (3) Immerse the nickel strip treated in (2) in the second-step treatment solution at 40°C for 8 minutes, and clean it with tap water;

[0073] (4) The nickel strip treated in (3) is heated and dried at 80°C.

Embodiment 3

[0075] The preparation of treatment liquid: the first step treatment liquid is c, and the second step treatment liquid is h;

[0076] Approach:

[0077] (1) Remove the grease from the nickel strip on the surface and clean it with tap water;

[0078] (2) Immerse the nickel strip treated in (1) in the first step treatment solution at 40°C for 6 minutes, and clean it with tap water;

[0079] (3) Immerse the nickel strip treated in (2) in the second-step treatment solution at 40°C for 8 minutes, and clean it with tap water;

[0080] (4) The nickel strip treated in (3) is heated and dried at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com