Chromium-free environment-friendly insulating coating for oriented silicon steel

A technology of oriented silicon steel and insulating coatings, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., can solve problems such as environmental pollution of hexavalent chromium compounds, achieve the effects of excellent performance, avoid environmental pollution, and reduce iron loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

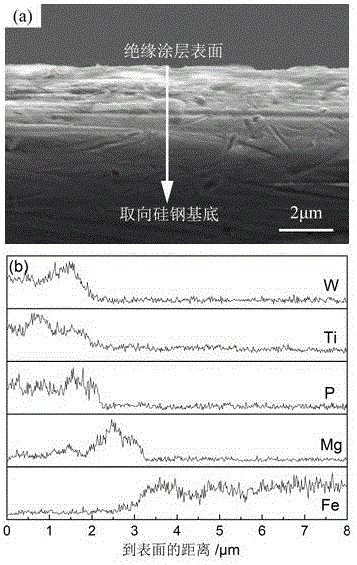

[0027] A chromium-free environmental protection insulating coating for oriented silicon steel, which is composed of 1.2% sodium tungstate, 1.8% ammonium tungstate, 2% titanium oxysulfate, 36% aluminum dihydrogen phosphate aqueous solution (aluminum dihydrogen phosphate content 40wt%), 9% magnesium dihydrogen phosphate aqueous solution (magnesium dihydrogen phosphate content is 30wt%), 30% silica sol (SiO 2 The content is 20wt%), 20% deionized water are mixed and stirred evenly, and the required environmentally friendly insulating coating for oriented silicon steel is prepared.

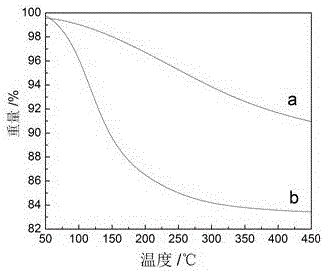

[0028] The prepared insulating coating is coated on both sides of the oriented silicon steel surface by a roller coater. 2 Under a protective atmosphere, the insulating coating is formed by baking at 450°C for 55s and sintering at 800°C for 60s. The grain-oriented silicon steel sample with insulating coating was placed at 820°C, N 2 Keep it warm for 2 hours under a protective atmosphere, and perform ...

Embodiment 2

[0036] A chromium-free environmentally friendly insulating coating for oriented silicon steel, composed of 1.3% ammonium tungstate, 1.2% titanium oxysulfate, 27% aqueous solution of aluminum dihydrogen phosphate (the content of aluminum dihydrogen phosphate is 45wt%), 22.5 % magnesium dihydrogen phosphate aqueous solution (magnesium dihydrogen phosphate content is 35wt%), 38% silica sol (SiO 2 The content is 26wt%), 10% deionized water are mixed and stirred evenly, and the required environmentally friendly insulating coating for oriented silicon steel is prepared.

[0037] The prepared insulating coating is double-coated on the surface of oriented silicon steel by a roller coater, and is baked at 400°C for 30s and sintered at 780°C for 75s in an Ar protective atmosphere to form an insulating coating. The grain-oriented silicon steel sample with insulating coating was placed at 820°C, N 2 Keep it warm for 2 hours under a protective atmosphere, and perform stress relief anneali...

Embodiment 3

[0045] A chromium-free environmentally friendly insulating coating for oriented silicon steel, which is composed of 1% lithium tungstate, 1% sodium tungstate, 5% titanium oxysulfate, 33% aqueous solution of aluminum dihydrogen phosphate (aluminum dihydrogen phosphate content is 50wt%), 8% zinc dihydrogen phosphate aqueous solution (zinc dihydrogen phosphate content is 60wt%), 28% silica sol (SiO 2 The content is 30wt%), 24% deionized water is mixed according to the formula ratio and stirred evenly to prepare the required environmentally friendly insulating coating for oriented silicon steel.

[0046] The prepared insulating coating is coated on both sides of the oriented silicon steel surface by a roller coater. 2 Under a protective atmosphere, the insulating coating is formed by baking at 420°C for 70s and sintering at 820°C for 35s. The grain-oriented silicon steel sample with insulating coating was placed at 820°C, N 2 Keep it warm for 2 hours under a protective atmospher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com