Ultrahigh-plasticity aluminum alloy and preparing method thereof

An aluminum alloy and plasticity technology, applied in the field of ultra-high plasticity aluminum alloy and its preparation, can solve the problems of reducing the mechanical properties of the alloy, splitting the matrix, etc., and achieve the effects of improving production efficiency, meeting application requirements, and good tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

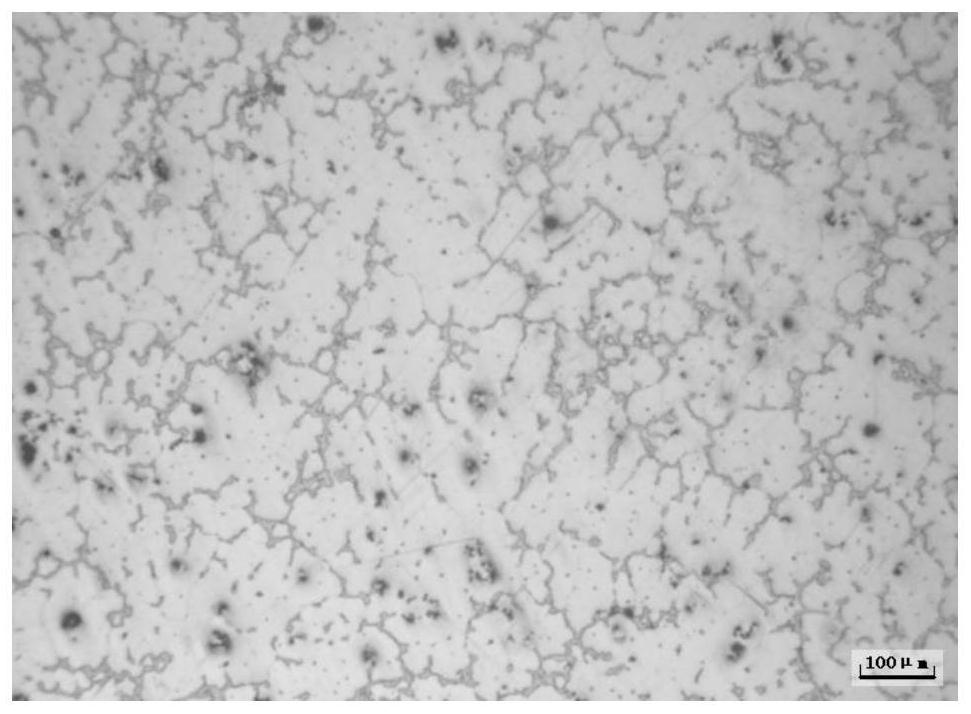

Embodiment 1

[0024] An ultra-high ductility aluminum alloy is composed of the following components by weight percentage: 0.8-1.2% of Mg, 0.4-0.8% of Si, 0.2-0.4% of Fe, 0.2-0.5% of Cu, and the rest is Al.

[0025] The ultra-high ductility aluminum alloy in this embodiment is made by following steps:

[0026] S1. Alloy smelting: According to 0.8-1.2% of Mg, 0.4-0.8% of Si, 0.2-0.4% of Fe, 0.2-0.5% of Cu, and the rest is Al, weigh appropriate amount of pure aluminum ingot, pure magnesium ingot, Al -Si master alloy, Al-Cu master alloy and Al-Fe master alloy are used as raw materials for batching, and the alloy ingredients are melted and cast into alloy ingots; in this embodiment, semi-continuous casting is used to prepare alloy ingots, and semi-continuous casting The alloy ingredients are preheated to 40-80°C first, then heated to 750-800°C for smelting, fully stirred after melting, left to stand, and then cooled to 700-750°C for casting.

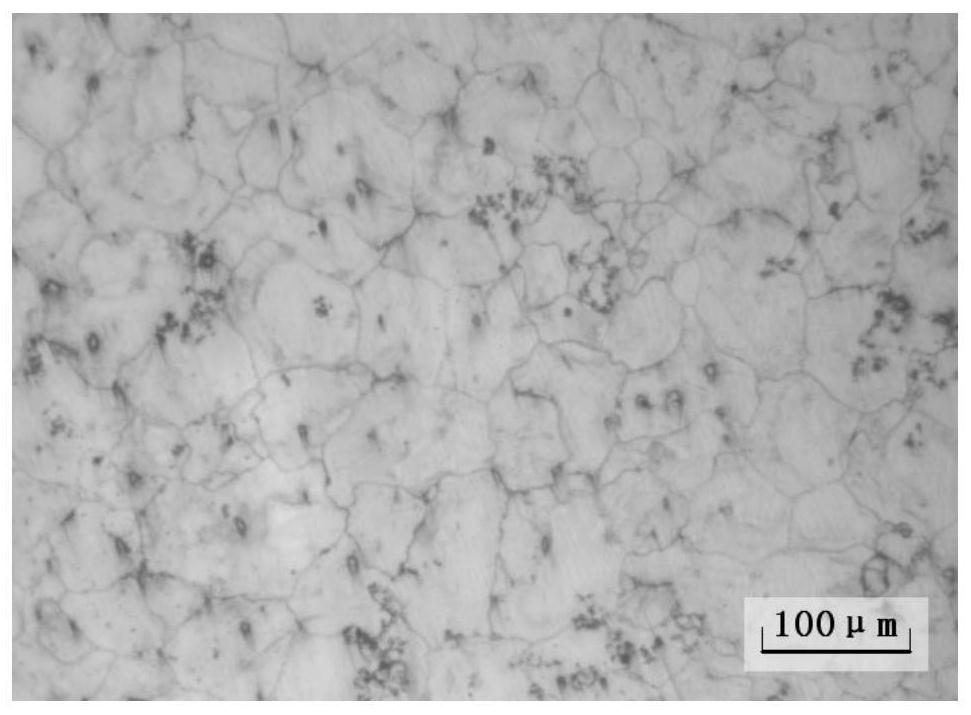

Embodiment 2

[0031] 1) Alloy smelting: using pure aluminum ingots, pure magnesium ingots, Al-Si master alloys, Al-Cu master alloys and Al-Fe master alloys as raw materials, according to Mg0.8%, Si0.5%, Cu0.5%, Fe is 0.3%, and the rest is the weight percentage of Al for batching. The alloy batching is preheated to 50°C, and then heated to 760°C for smelting, fully stirred after melting, left to stand, and cooled to 720°C for casting.

[0032] 2) Machining: the alloy ingot is turned into a cylindrical extrusion billet with a diameter of 80 mm and a length of 100 mm.

[0033] 3) Extrusion forming: Preheat the extrusion billet and mold at 400°C for 1 hour before extrusion, and then press the extrusion temperature at 500°C, the extrusion ratio at 45, and the extrusion speed at 15m / min. Just take shape.

[0034] The mechanical properties of the deformed aluminum alloy material prepared in this example are specifically shown as the tensile yield strength at room temperature is 359 MPa, the tensi...

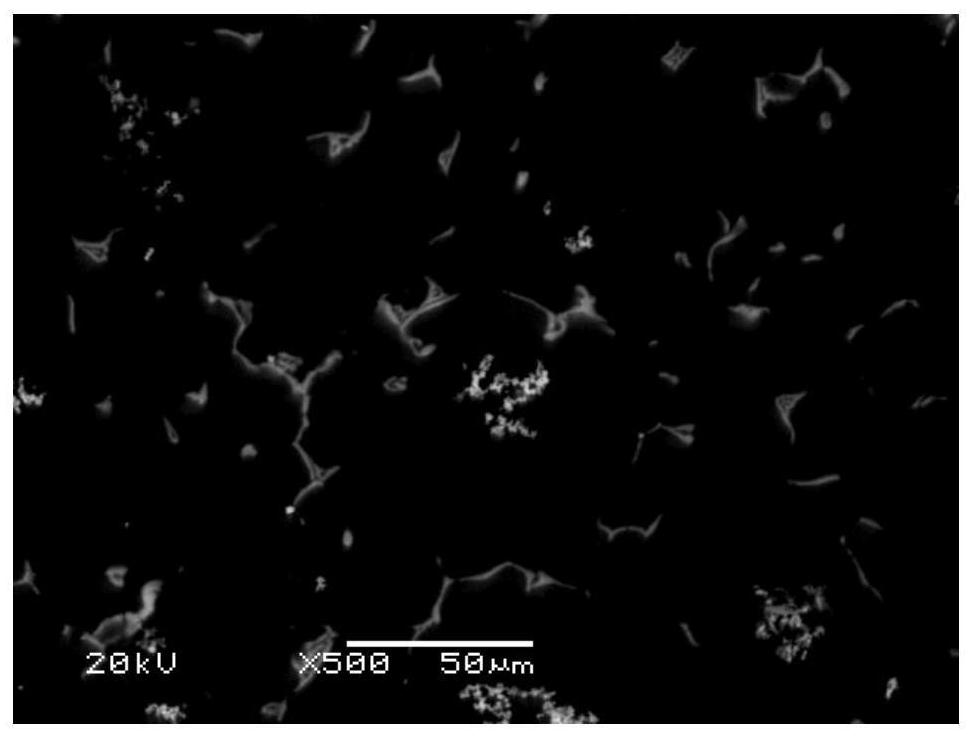

Embodiment 3

[0036] 1) Alloy smelting: using pure aluminum ingots, pure magnesium ingots, Al-Si master alloys, Al-Cu master alloys and Al-Fe master alloys as raw materials, according to Mg1.0%, Si0.6%, Cu0.2%, Fe is 0.4%, and the rest is the weight percentage of Al for batching. The alloy batching is preheated to 50°C, and then heated to 760°C for smelting, fully stirred after melting, left to stand, and cooled to 710°C for casting.

[0037] 2) Machining: the alloy ingot is turned into a cylindrical extrusion billet with a diameter of 80 mm and a length of 100 mm.

[0038] 3) Extrusion forming: Preheat the extrusion billet and mold at 400°C for 1 hour before extrusion, and then press the extrusion temperature at 510°C, extrusion ratio at 29, and extrusion speed at 15m / min. Just take shape.

[0039] The mechanical properties of the aluminum alloy deformed material prepared in this example are specifically shown as the tensile yield strength at room temperature is 342 MPa, the tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com