Novel aluminum alloy door and window sectional material and preparation method thereof

A new type of technology for aluminum alloy doors and windows, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of shortening the service life of aluminum alloy profiles, poor vibration and noise reduction, and lack of vibration and noise reduction. , to achieve the effects of improving comprehensive performance, reducing coarse undissolved crystalline phase, and excellent fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

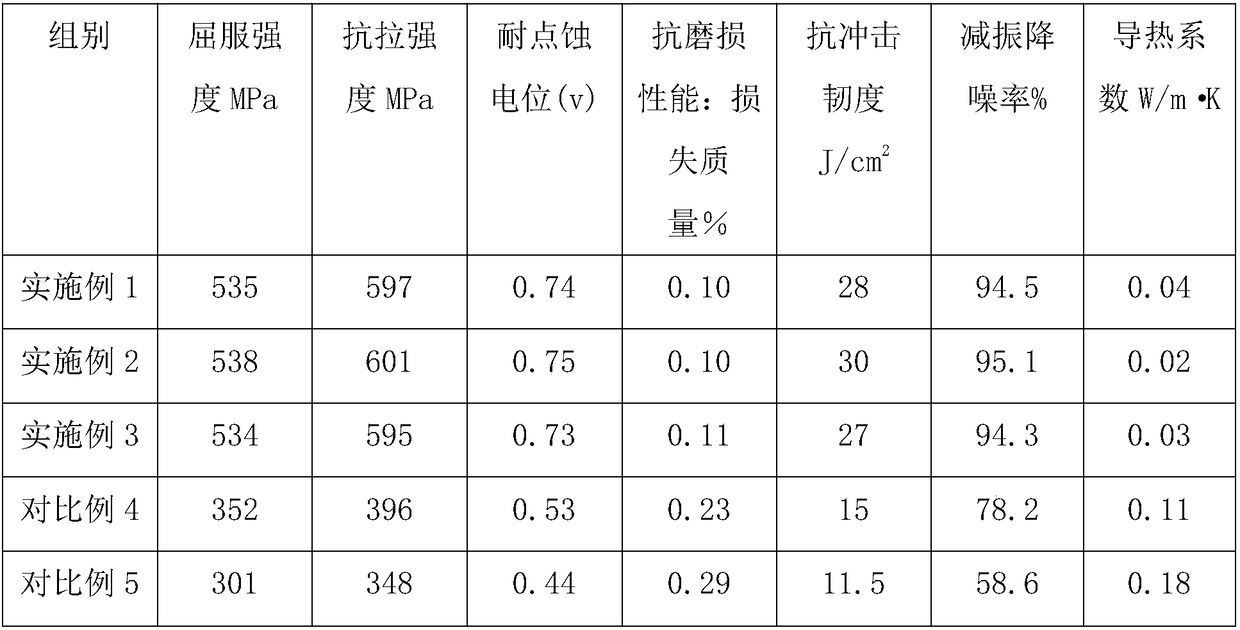

Examples

Embodiment 1

[0034] A new aluminum alloy door and window profile, including the following chemical composition by weight percentage: Fe: 0.21%, Mn: 0.62%, Ti: 0.11%, Cu: 0.03%, Mg: 0.54%, Co: 0.85%, Sb: 0.46%, Te: 0.01%, Mo: 0.72%, Zr: 0.07%, Nb: 0.16%, Sc: 0.05%, Ce: 0.006%, N: 0.005%, and the balance is Al.

[0035] The preparation method of this novel aluminum alloy door and window profile is carried out according to the following steps:

[0036] (1) First put the scrap aluminum in the smelting furnace, heat the furnace to 720°C, and after it is completely melted, keep the molten aluminum for 35 minutes; then heat it at a heating rate of 10°C / s, and use nitrogen to push other alloys and powders The raw materials are added to the melting furnace for melting, and after the melting is completed, keep warm for 1.5 hours;

[0037] (2) Cool down the molten aluminum alloy obtained in step (1) to 680°C at a rate of 4°C / min, spray the refining agent after holding it for 15 minutes, then raise t...

Embodiment 2

[0053] A new aluminum alloy door and window profile, including the following chemical composition by weight percentage: Fe: 0.24%, Mn: 0.66%, Ti: 0.13%, Cu: 0.045%, Mg: 0.56%, Co: 0.95%, Sb: 0.49%, Te: 0.02%, Mo: 0.75%, Zr: 0.09%, Nb: 0.20%, Sc: 0.10%, Ce: 0.008%, N: 0.003%, and the balance is Al.

[0054] The preparation method of this novel aluminum alloy door and window profile is carried out according to the following steps:

[0055] (1) First put the scrap aluminum in the smelting furnace, heat the furnace to 730°C, and after it is completely melted, keep the molten aluminum for 40 minutes; then heat it at a heating rate of 10°C / s, and use nitrogen to push other alloys and powders The raw materials are added to the melting furnace for melting, and after the melting is completed, keep warm for 2 hours;

[0056] (2) Cool down the aluminum alloy melt obtained in step (1) to 685°C at a rate of 6°C / min, spray the refining agent after holding it for 18 minutes, then raise the ...

Embodiment 3

[0072] A new aluminum alloy door and window profile, including the following chemical composition by weight percentage: Fe: 0.27%, Mn: 0.70%, Ti: 0.15%, Cu: 0.06%, Mg: 0.58%, Co: 1.05%, Sb: 0.52%, Te: 0.03%, Mo: 0.78%, Zr: 0.11%, Nb: 0.24%, Sc: 0.15%, Ce: 0.01%, N: 0.005%, and the balance is Al.

[0073] The preparation method of this novel aluminum alloy door and window profile is carried out according to the following steps:

[0074] (1) Put the scrap aluminum in the smelting furnace first, heat the furnace to 740°C, and after it is completely melted, keep the molten aluminum for 45 minutes; then heat it at a heating rate of 15°C / s, and use nitrogen to push other alloys and powders The raw materials are added to the melting furnace for melting, and after the melting is completed, keep warm for 2 hours;

[0075] (2) Cool down the aluminum alloy melt obtained in step (1) to 690°C at a rate of 8°C / min, spray the refining agent after holding it for 20 minutes, then raise the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com