Copper-based bonding wire with nickel-plated surface and preparation method thereof

A bonding wire, copper-based technology, applied in semiconductor/solid-state device manufacturing, circuits, electric solid-state devices, etc., can solve poor oxidation resistance, hardness and tensile properties, high hardness, unreliable welding, and poor device stability and other problems, to achieve the effect of improving oxidation resistance, easy control of shape, and stable welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

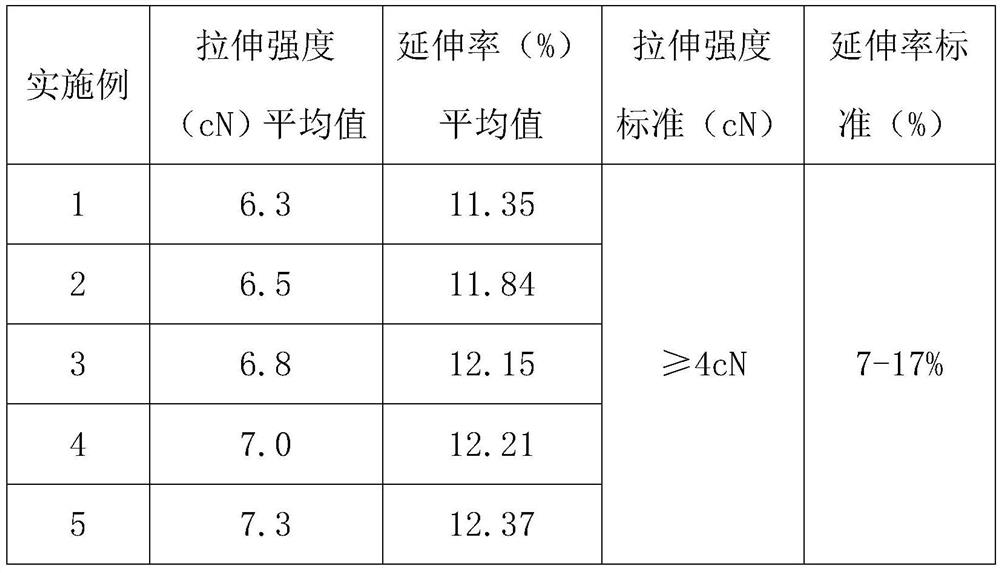

Embodiment 1

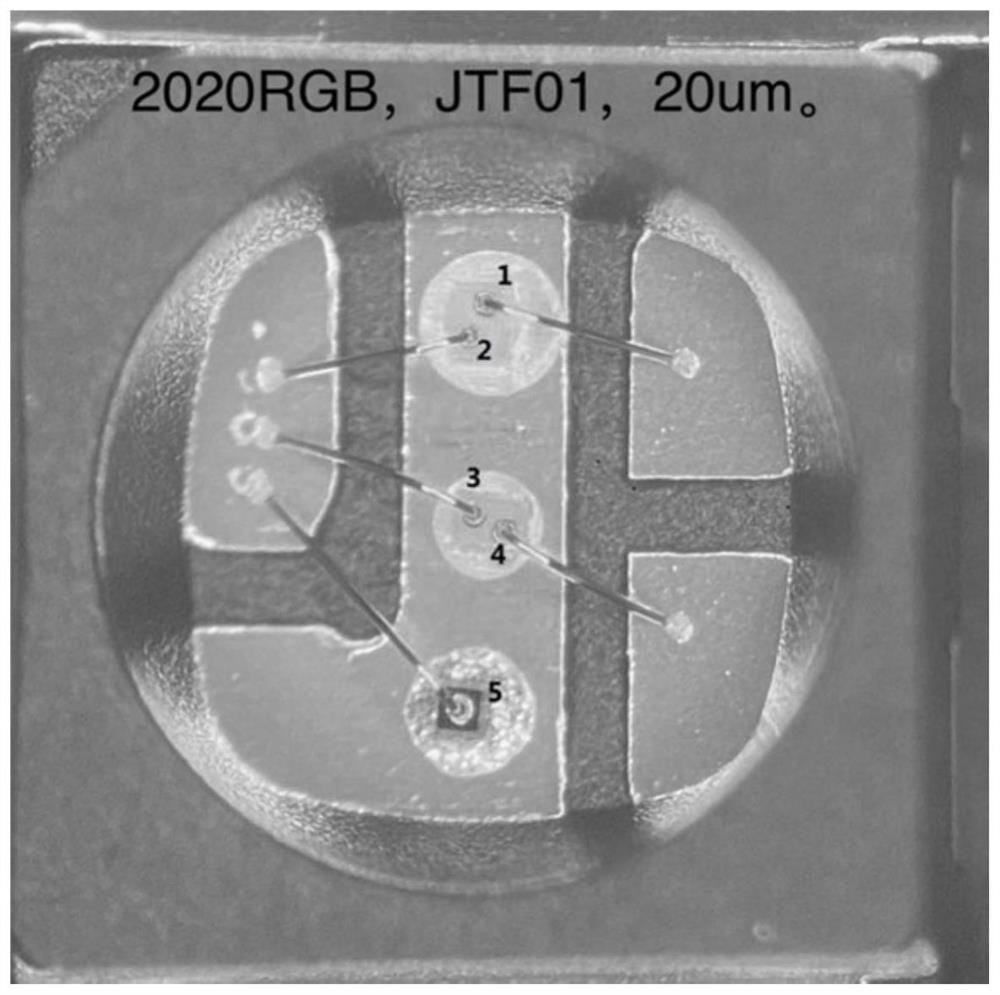

[0030] A method for preparing a nickel-plated copper-based bonding wire, comprising the steps of:

[0031] 1) Raw material preparation and pretreatment: all metal raw materials are cleaned and dried by ultrasonic technology with absolute ethanol;

[0032] The metal copper accounts for 99.99%, the trace addition of manganese accounts for 0.002%, tungsten accounts for 0.004%, boron accounts for 0.002%, and zirconium accounts for 0.002%;

[0033] 2) Substrate melting and casting: Mix the dried metal raw materials, and conduct vacuum melting under the atmosphere of high-purity argon gas, the vacuum degree is 0.001MPa, the melting temperature is 1050°C, and the melting time is 50 minutes, and then orientation is carried out Continuous casting to obtain a copper-based master alloy wire with a diameter of 50 μm;

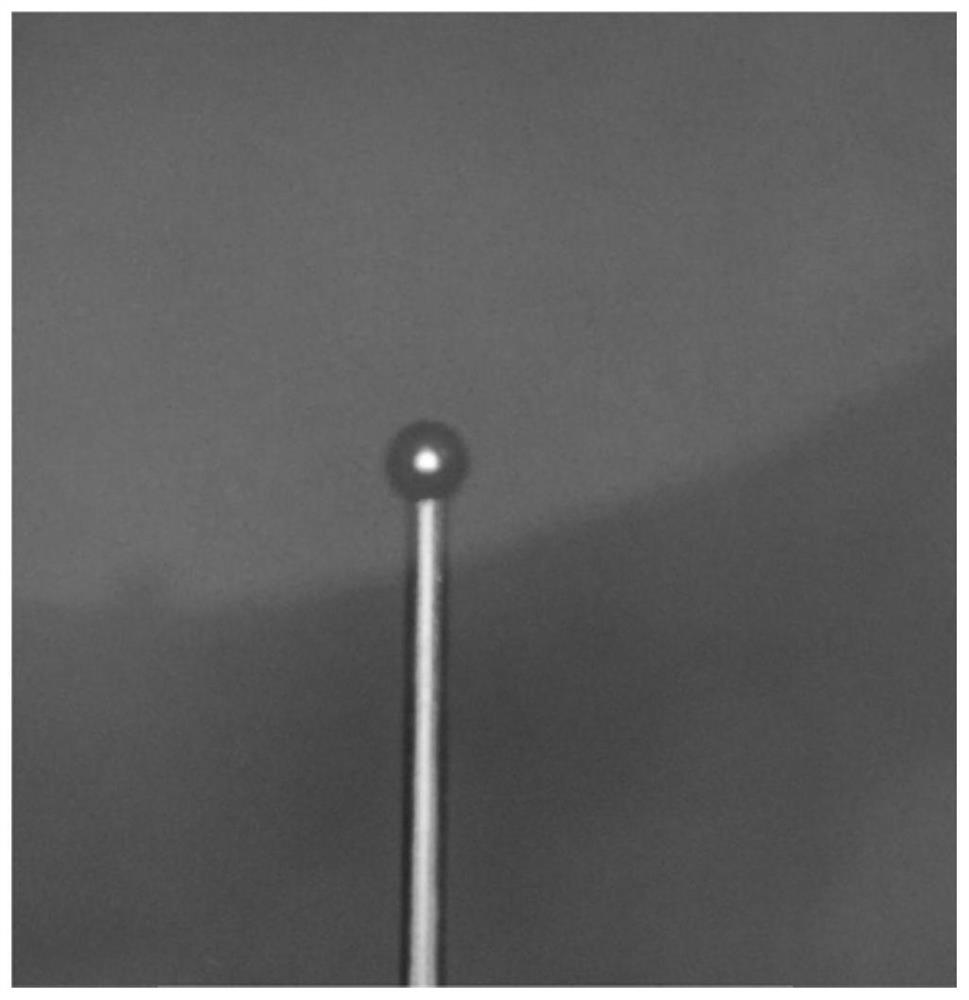

[0034] 3) Cold drawing: cooling the copper-based master alloy to 150°C, performing rough drawing to make the diameter 20 μm, and then performing fine drawing to make the d...

Embodiment 2

[0040] A method for preparing a nickel-plated copper-based bonding wire, comprising the steps of:

[0041] 1) Raw material preparation and pretreatment: all metal raw materials are cleaned and dried by ultrasonic technology with absolute ethanol;

[0042] The metal copper accounts for 99.993%, the trace addition of manganese accounts for 0.002%, tungsten accounts for 0.002%, boron accounts for 0.002%, and zirconium accounts for 0.001%;

[0043] 2) Substrate melting and casting: Mix the dried metal raw materials, and carry out vacuum melting under the atmosphere of high-purity argon gas, the vacuum degree is 0.005MPa, the melting temperature is 1150°C, and the melting time is 60 minutes, and then the orientation is carried out Continuous casting to obtain a copper-based master alloy wire with a diameter of 60 μm;

[0044] 3) Cold drawing: cooling the copper-based master alloy to 160°C, performing rough drawing to make the diameter 25 μm, and then performing fine drawing to mak...

Embodiment 3

[0050] A method for preparing a nickel-plated copper-based bonding wire, comprising the steps of:

[0051] 1) Raw material preparation and pretreatment: all metal raw materials are cleaned and dried by ultrasonic technology with absolute ethanol;

[0052] The metal copper accounts for 99.996%, the trace addition of manganese accounts for 0.001%, tungsten accounts for 0.001%, boron accounts for 0.001%, and zirconium accounts for 0.001%;

[0053] 2) Substrate melting and casting: Mix the dried metal raw materials, and carry out vacuum melting in the atmosphere of high-purity argon, the vacuum degree is 0.008MPa, the melting temperature is 1200°C, and the melting time is 70 minutes, and then the orientation is carried out Continuous casting to obtain a copper-based master alloy wire with a diameter of 60 μm;

[0054] 3) Cold drawing: cooling the copper-based master alloy to 170°C, performing rough drawing to make the diameter 25 μm, and then performing fine drawing to make the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com