A kind of manufacturing method and manufacturing equipment of low-loss optical fiber

A manufacturing method and a technology for manufacturing equipment, which are applied in the field of optical fiber manufacturing, can solve problems such as damage, ineffectiveness, and reduced functions of components and surrounding component groups, and achieve the effects of reducing Rayleigh scattering, simple scheme, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

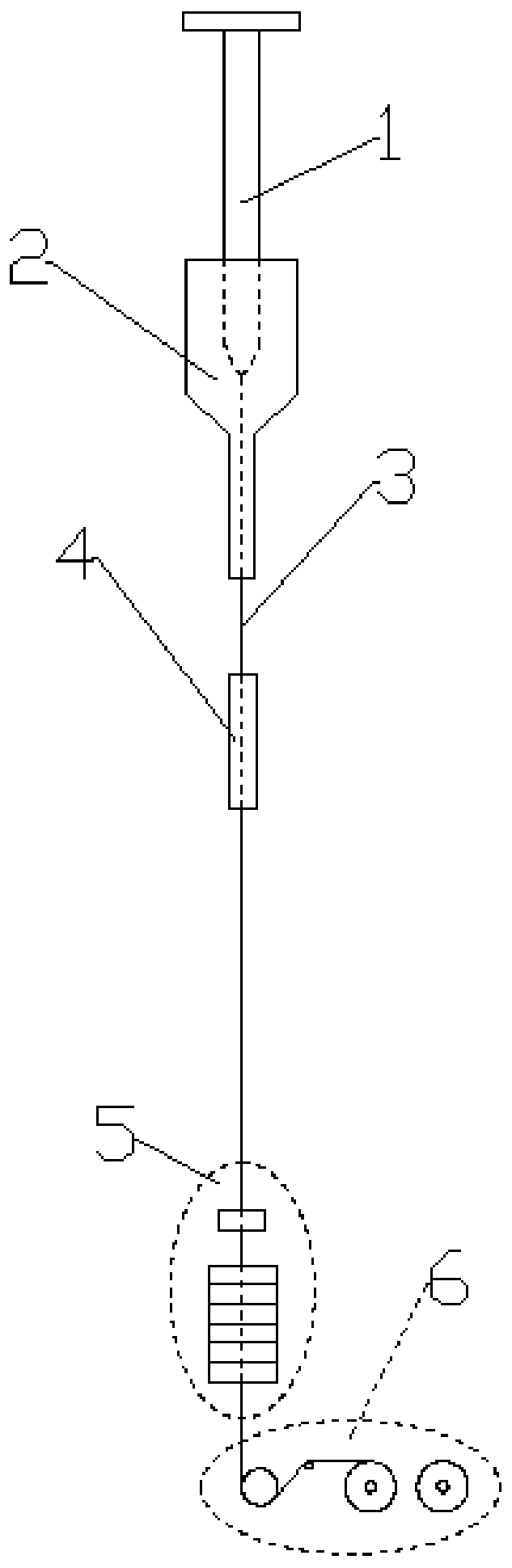

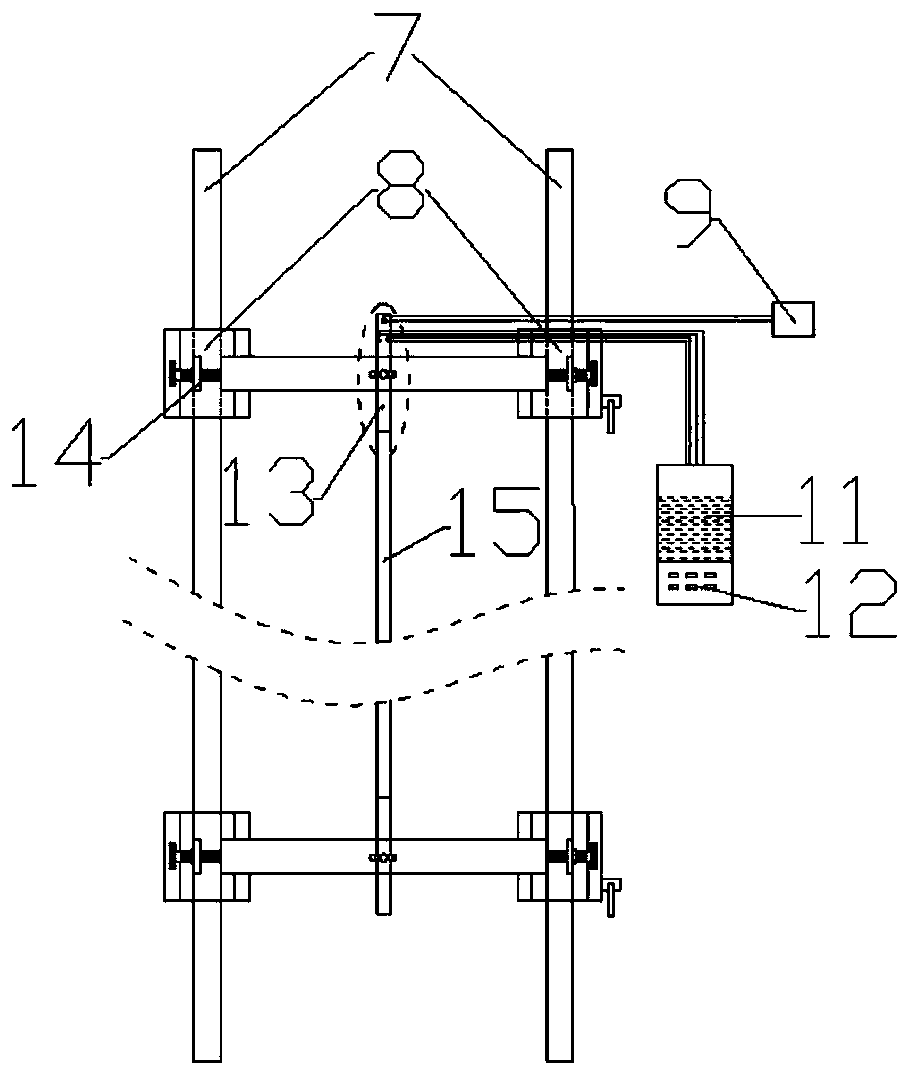

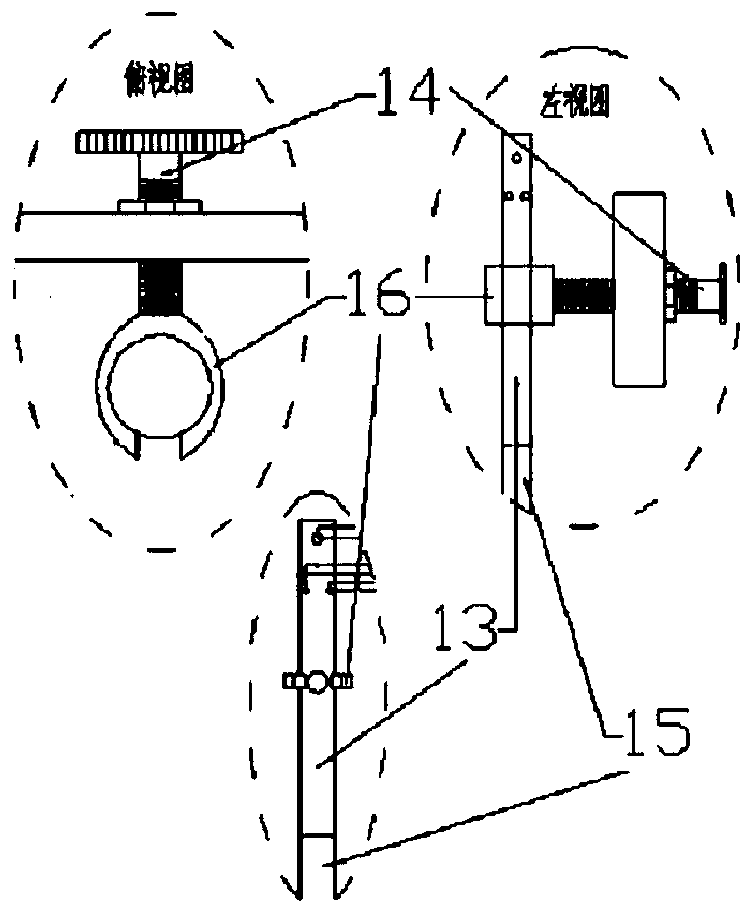

[0042] Manufacturing method of low-loss optical fiber X1

[0043] 40cm below the wire drawing furnace 2, facing the position of the outlet of the wire drawing furnace, the plexiglass tube 15 connected at both ends is vertically set, the length of the plexiglass tube 15 is 50cm, and the diameter is 4cm. The glass tube wall is oppositely provided with air-tight air holes, each air-tight air hole is sealed with a gas pipe, and the end of each air pipe communicates with a nitrogen source that provides nitrogen, and the nitrogen source controls the flow into the air pipe through the gas flow control device 9, so that The amount of nitrogen entering the plexiglass tube 15 meets the requirements of the air seal; four water vapor holes are arranged at intervals on the plexiglass tube wall below the air seal pore 10 cm away from the air seal pore, and each water steam hole is sealed and connected with a water vapor hole. Steam pipes, the ends of each water vapor pipe are in communicati...

Embodiment 2

[0046] Manufacturing method of low-loss optical fiber X2

[0047] 60cm below the wire drawing furnace 2 is facing the position of the outlet of the wire drawing furnace, vertically set the plexiglass tube 15 connected at both ends, the length of the plexiglass tube 15 is 60cm, the diameter is 6cm, and the organic glass tube 15 at the distance from the upper nozzle 20cm The glass tube wall is oppositely provided with gas-sealed air holes, each air-sealed air hole is sealed with a gas pipe, and the end of each gas pipe communicates with a nitrogen source that provides nitrogen, and the nitrogen source controls the flow into the gas pipe through the gas flow control device 9; Four water vapor pipe holes are arranged at intervals on the plexiglass tube wall 15cm away from the air seal air hole below the air seal air hole, each water steam hole is sealed and connected with a water vapor pipe, and the end of each water vapor pipe is connected to the water tank 11 communicates, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com