Method for manufacturing large-diameter optical fiber mandril through PCVD process

An optical fiber core and large diameter technology, which is applied in the manufacture of optical fiber core rods, and in the field of manufacturing large diameter optical fiber core rods by PCVD process, can solve the problems of preform attenuation water peak, rise, etc., to reduce moisture content and reduce doping amount , the effect of high deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

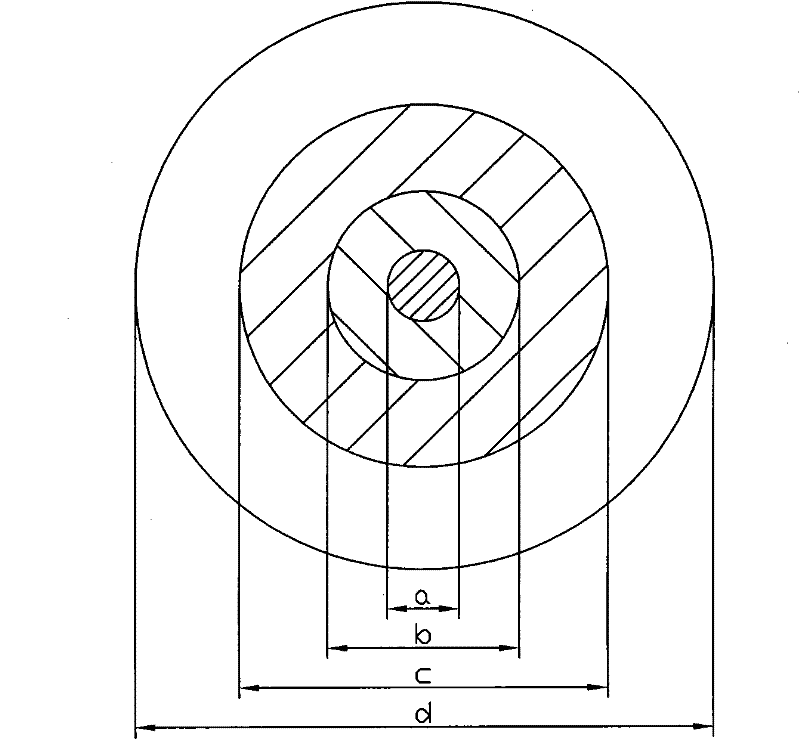

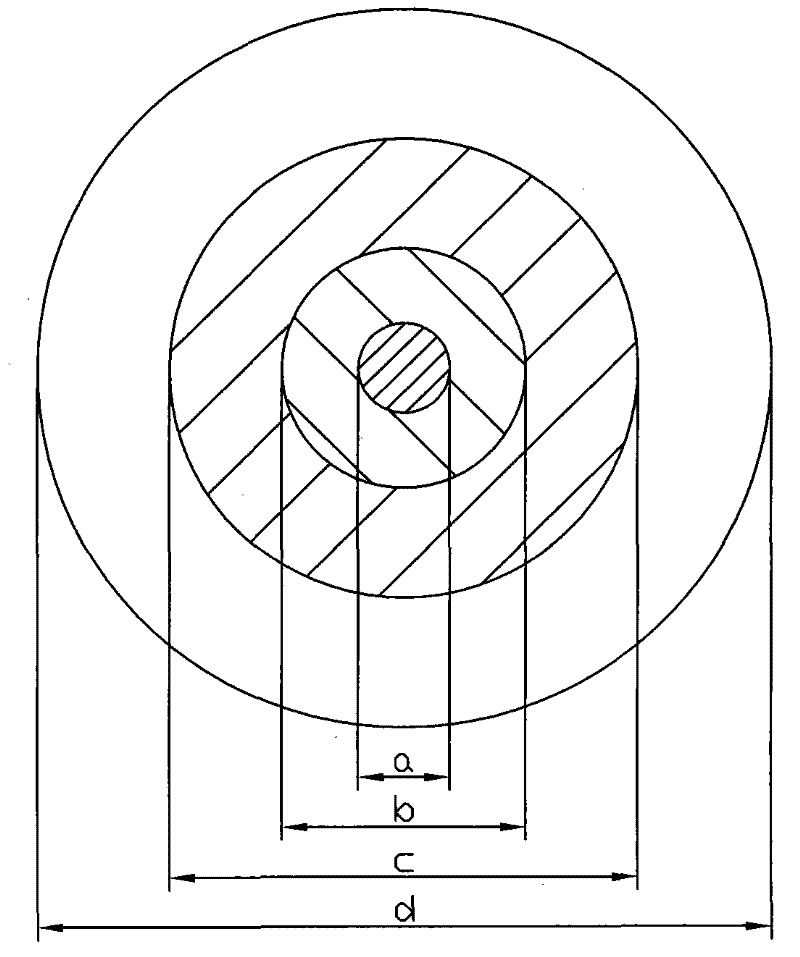

Image

Examples

Embodiment 1

[0035] Realize the manufacture of Φ58 large-diameter single-mode G.652.D fiber core rod with high deposition rate PCVD process, using a quartz liner with an outer diameter of 61 mm, an inner diameter of 35 mm, and a length of 1.70 meters. The liner uses Suprasil from Heraeus, Germany F500 high-purity low-hydroxyl synthetic quartz material is installed on the deposition lathe to start deposition after both ends are extended, corroded and cleaned. The cladding deposition rate is 3.8g / min, and the deposition efficiency is 91%. The following table illustrates the deposition process parameters.

[0036] Table 3-1 Main technical parameters of G.652.D large-diameter mandrel deposition process

[0037] parameter name

wrapping

core layer

SiCl4+GeCl4 vapor volume flow rate (sccm)

1900

1600

Deposition rate g / min

3.8

3.3

High-purity oxygen flow rate (sccm)

5700

4800

C2F6 gas volume flow rate (sccm)

90

...

Embodiment 2

[0045] Realize the manufacture of Φ49 large-diameter single-mode G.652.D fiber core rod with high deposition rate PCVD process, using a quartz liner with an outer diameter of 55 mm, an inner diameter of 35 mm, and a length of 1.55 meters. The liner uses Suprasil from Heraeus, Germany F500 high-purity low-hydroxyl synthetic quartz material is installed on the deposition lathe to start deposition after both ends are extended, corroded and cleaned. The cladding deposition rate is 4.5g / min, and the deposition efficiency is 89%. The following table illustrates the deposition process parameters.

[0046] Table 3-1 Main technical parameters of G.652.D large-diameter mandrel deposition process

[0047] parameter name

wrapping

core layer

SiCl4+GeCl4 vapor volume flow rate (sccm)

2300

2100

Deposition rate g / min

4.5

4.1

High-purity oxygen flow rate (sccm)

6900

6300

C2F6 gas volume flow rate (sccm)

190 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com