Inner cladding depressed type multimode optical fibre prefabricated rod

A multi-mode fiber, preform technology, used in glass fiber products, optics, light guides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

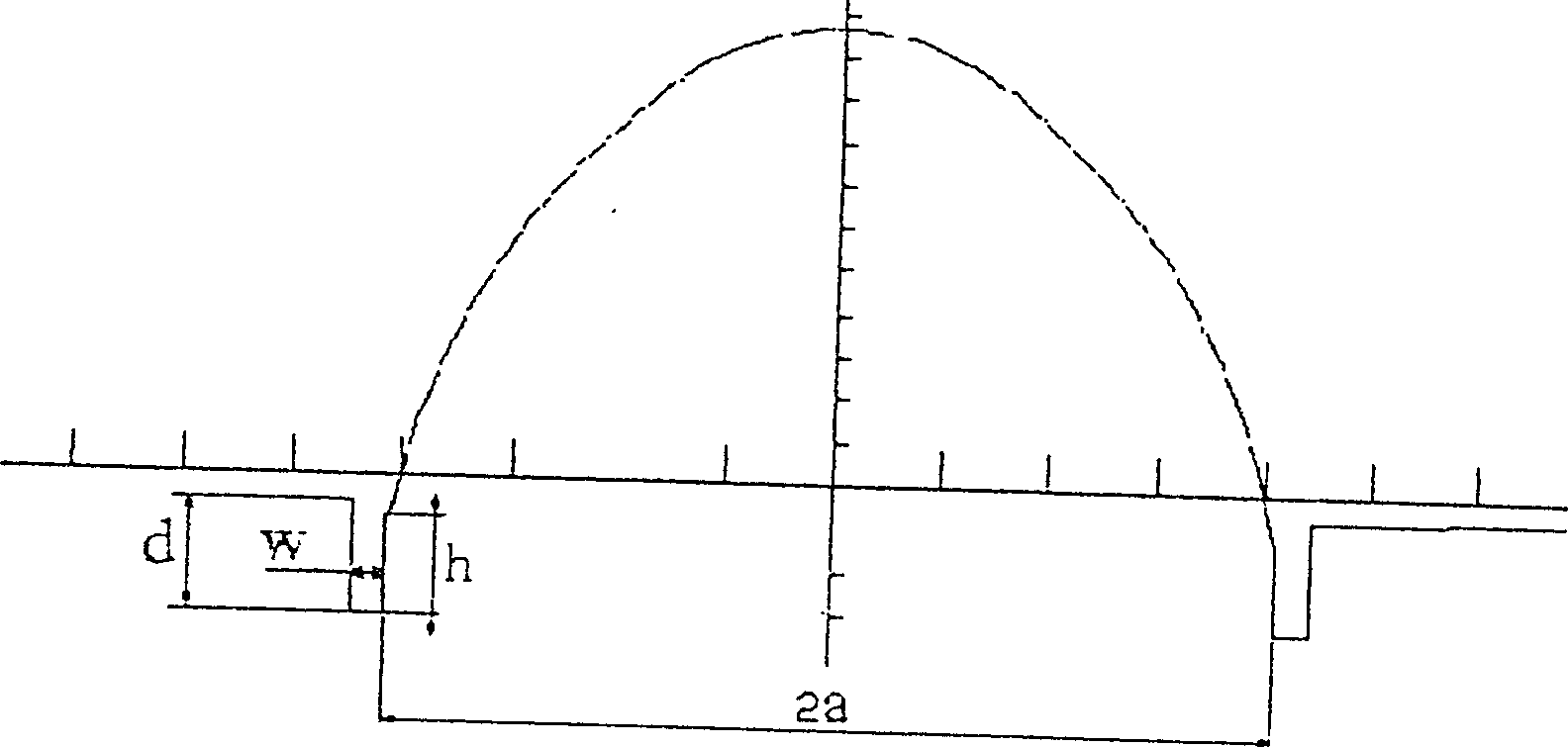

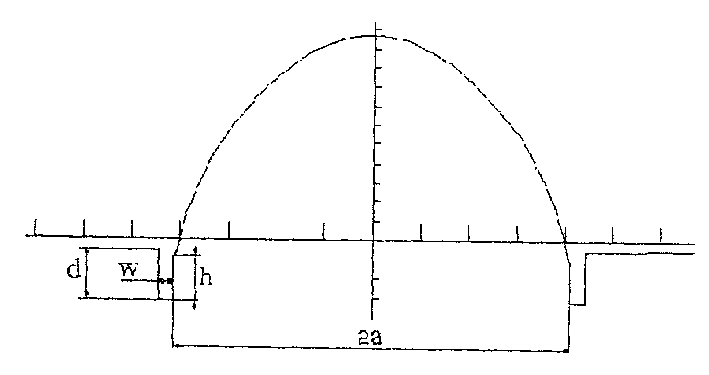

[0058] Embodiment 1 The waveguide structure of the present invention is:

[0059] The depression depth d is -0.60%;

[0060] The ratio of the width w of the depression to the diameter 2a of the core of the preform is 0.10%;

[0061] The starting point height h of the core is -0.60%;

Embodiment 2

[0062] Embodiment 2 The waveguide structure of the present invention is:

[0063] The depression depth d is -0.80%;

[0064] The ratio of the width w of the depression to the diameter 2a of the core of the preform is 2%;

[0065] The starting point height h of the core is -0.02%

Embodiment 3

[0066] Embodiment 3 The waveguide structure of the present invention is:

[0067] The depression depth d is -0.01%;

[0068] The ratio of the depression width w to the preform core diameter 2a is 5.00%;

[0069] The starting point height h of the core is 0.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com