Quick isothermal forging method and device for preparing less-deformable alloy cake blank

An isothermal forging and difficult-to-deform technology, applied in the field of warm forging, can solve the problems of easy oxidation, increase process complexity and cost, and very high requirements for mold materials, and achieve the effect of reducing the cost of forging process and reducing the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiment details: prepare the FGH96 alloy of φ 200mm and the FGH98 alloy cake blank

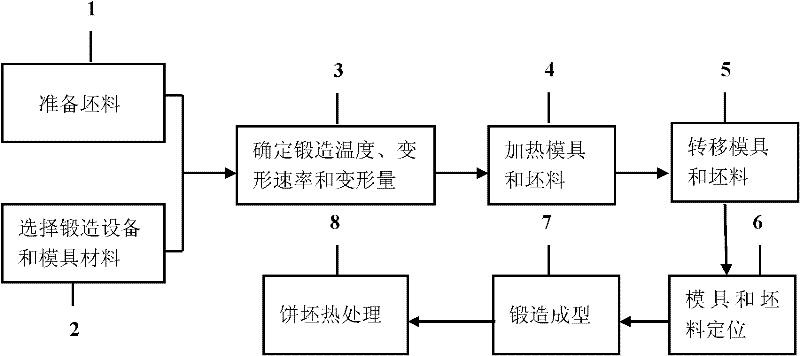

[0036] figure 1 It is the specific implementation method of the present invention. The first step is the preparation of the forging blank, which is a deformed nickel-based superalloy strengthened by the γ′ phase or its related phase. This preferred embodiment adopts FGH96 or FGH98 superalloy, the main chemical composition of FGH96 alloy is: C: 0.03wt%, Co: 13wt%, Cr: 16wt%, Mo: 4wt%, W: 4wt%, Ti: 3.7wt% , Al: 2.2wt%, Nb: 0.77wt%, B: 0.015wt%, Zr: 0.05wt%, Fe: ≤0.5wt%, Ni: I. The main chemical composition of FGH98 alloy is: C: 0.03wt%, Co: 18wt%, Cr: 13wt%, Mo: 3.8wt%, W: 2wt%, Ti: 3.5wt%, Al: 3.5wt%, Nb: 1.5 wt%, Ta: 2.7wt%, B: 0.03wt%, Zr: 0.05wt%, Fe: ≤ 0.5wt%, Ni: remainder.

[0037] Nickel-based superalloy forging ingots can be high-purity, low-segregation directional solidification ingots obtained by any operable process measures, but it is best to continuously di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com