Production technology for casting wear-resistant thin plates by compounding double liquid metals

A dual-liquid dual-metal, composite casting technology, applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., to avoid microscopic crack sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

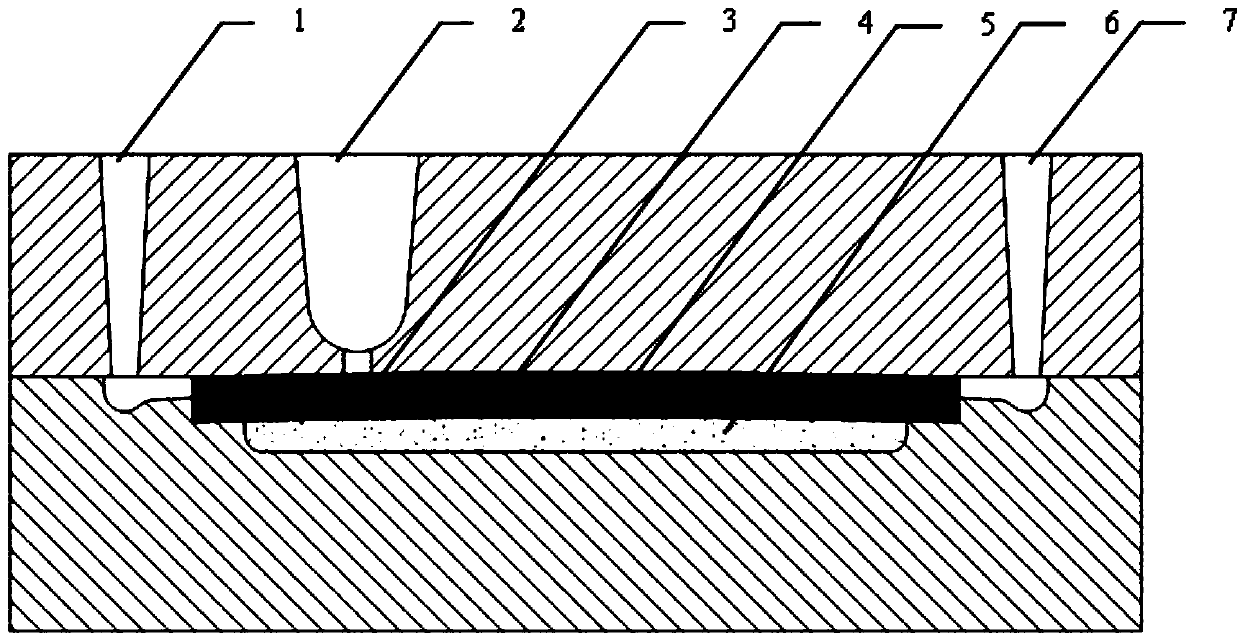

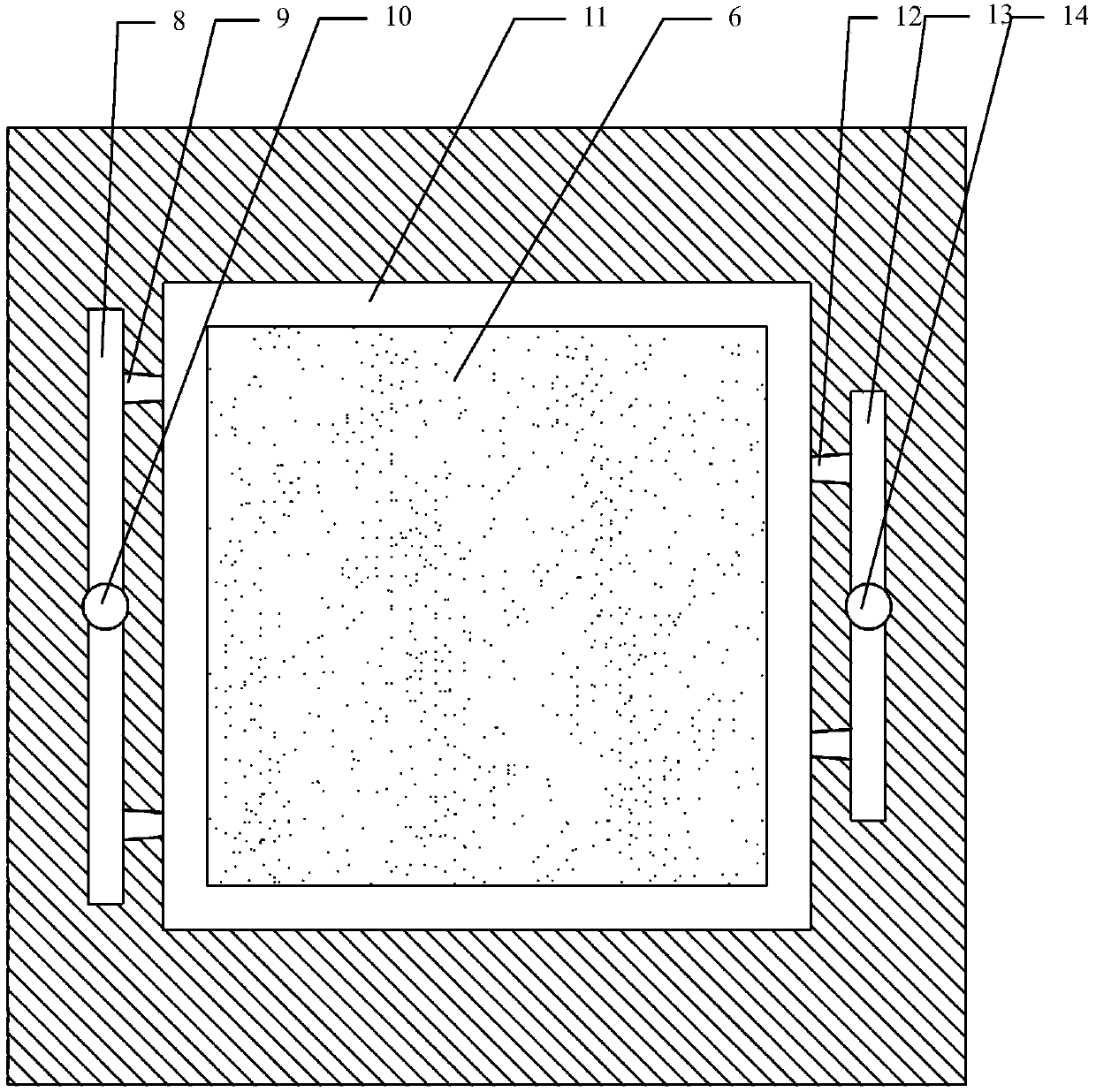

[0033] This embodiment provides a production process for a double-liquid bimetal composite casting wear-resistant thin plate, such as Figure 1-2 As shown, the specific steps are as follows:

[0034] KGPS-800 type 150kg and 250kg intermediate frequency melting furnaces, one set each, and the molding material is CO 2 Hardened sodium silicate sand, reserved anti-deformation amount of 3mm / m, combined with special chilling material (placed on the lower side of the middle area of the cavity) to change the traditional double pouring system design, and carry out the flat casting molding of the double pouring system, which is convenient for pouring Adjustment of the temperature field after the molten metal. The chilling material is formed by mixing zircon sand, steel shot and water glass in a mass ratio of 7:90:3.

[0035] Alloy composition design: low alloy steel, C: 0.32~0.45wt%, Cr: 0.60~0.80wt%, Mn: 0.60~0.70wt%, Mo: ≥0.2, Si: ≤0.4; high chromium cast iron, C: 2.8~ 3.1wt%, Cr...

Embodiment 2

[0039] KGPS-800 type 150kg and 250kg intermediate frequency melting furnaces, one set each, and the molding material is CO 2 For hardened water glass sand, the reserved anti-deformation amount is 2mm / m. The chilling material is made of zircon sand, steel shot and water glass mixed according to the mass ratio of 5:92:3, and placed on the lower side of the middle area of the cavity. Alloy composition design: low alloy steel, C: 0.36wt%, Cr: 1.0wt%, Mn: 1.3wt%, Si: 1.8wt%, RE: trace, S, P: ≤0.05wt%; high carbon high alloy steel , C: 2.05wt%, Cr: 12.5wt%, W: 1.3wt%; Mn: 0.8wt%, Si: 0.3wt%, S, P: ≤ 0.05wt%. The minimum height of the low-alloy molten steel poured into the base material can be controlled above 10mm, and the pouring temperature is 1450°C. According to the size and thickness of the wear-resistant layer, the time interval for pouring the high-carbon and high-alloy molten steel of the wear-resistant layer is 5 ~15s, the pouring temperature is 1550°C. The process is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com