Method for casting isometric crystal turbine work blade blanks

An equiaxed crystal and blade technology, applied in the field of axial crystal turbine working blade blank casting, can solve the problems of irreversible, not allowed to repair welding, scrapped blades, etc., and achieve the effect of improving metallurgical quality and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

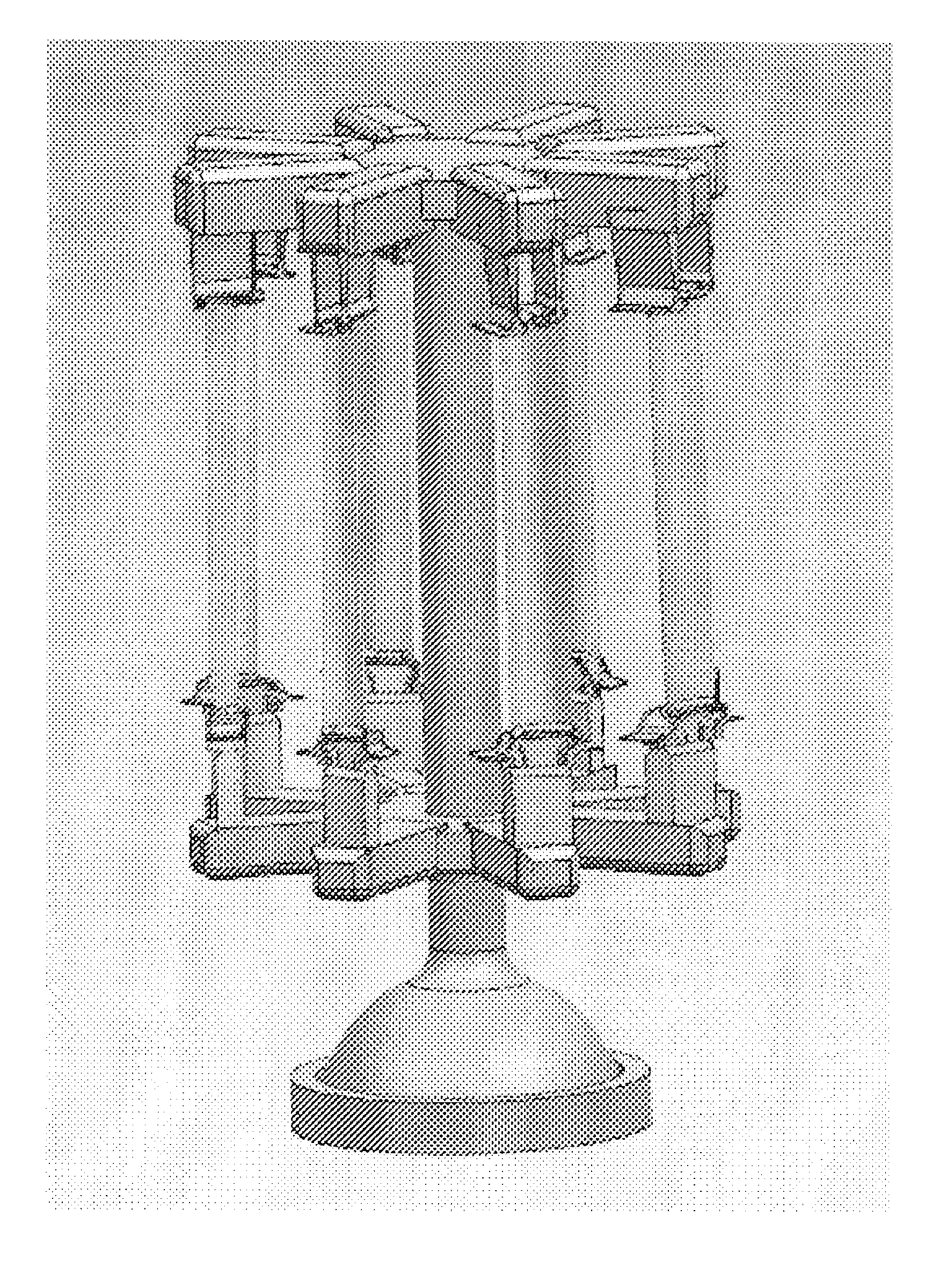

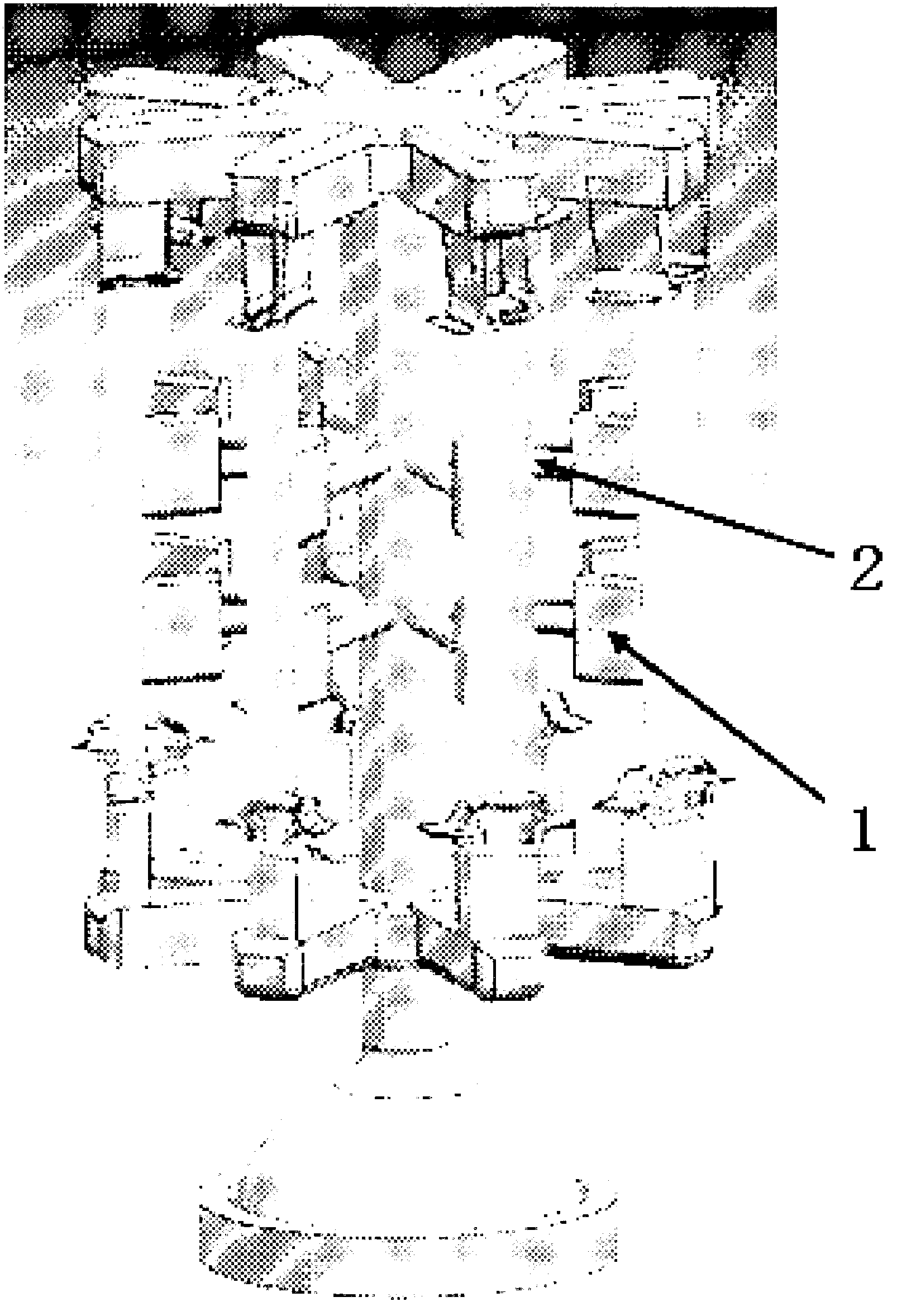

[0020] A blank casting method for equiaxed crystal turbine working blades: firstly, adopt bottom injection and top pouring pouring system; cast equiaxed crystal turbine working blades in groups, and each group of 4-20 working blades is distributed along the blade circumference; In the case of uniformity and uniform heat distribution (in order to ensure that the casting quality of each blade is consistent), in order to eliminate the loose defects inside the blade body, we paste the attached structure on the middle part of the blade back of each blade to be cast and connect it to the straight A feeding riser is formed on the runner, and finally a mixed pouring system of top injection, bottom injection and side injection is formed, so as to break the solidification sequence of the molten steel in the mold shell, so that the molten steel forms an effective feeding channel in the mold, and the The final solidification zone of the molten steel is lifted into the pouring riser and cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com