Turbomachine structural casing

A technology for structural frame and turbine, which is applied in gas turbine installations, mechanical equipment, engine manufacturing, etc., can solve problems such as complicated maintenance and operation of turbines, and achieve the effects of reducing size, improving metallurgical quality, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

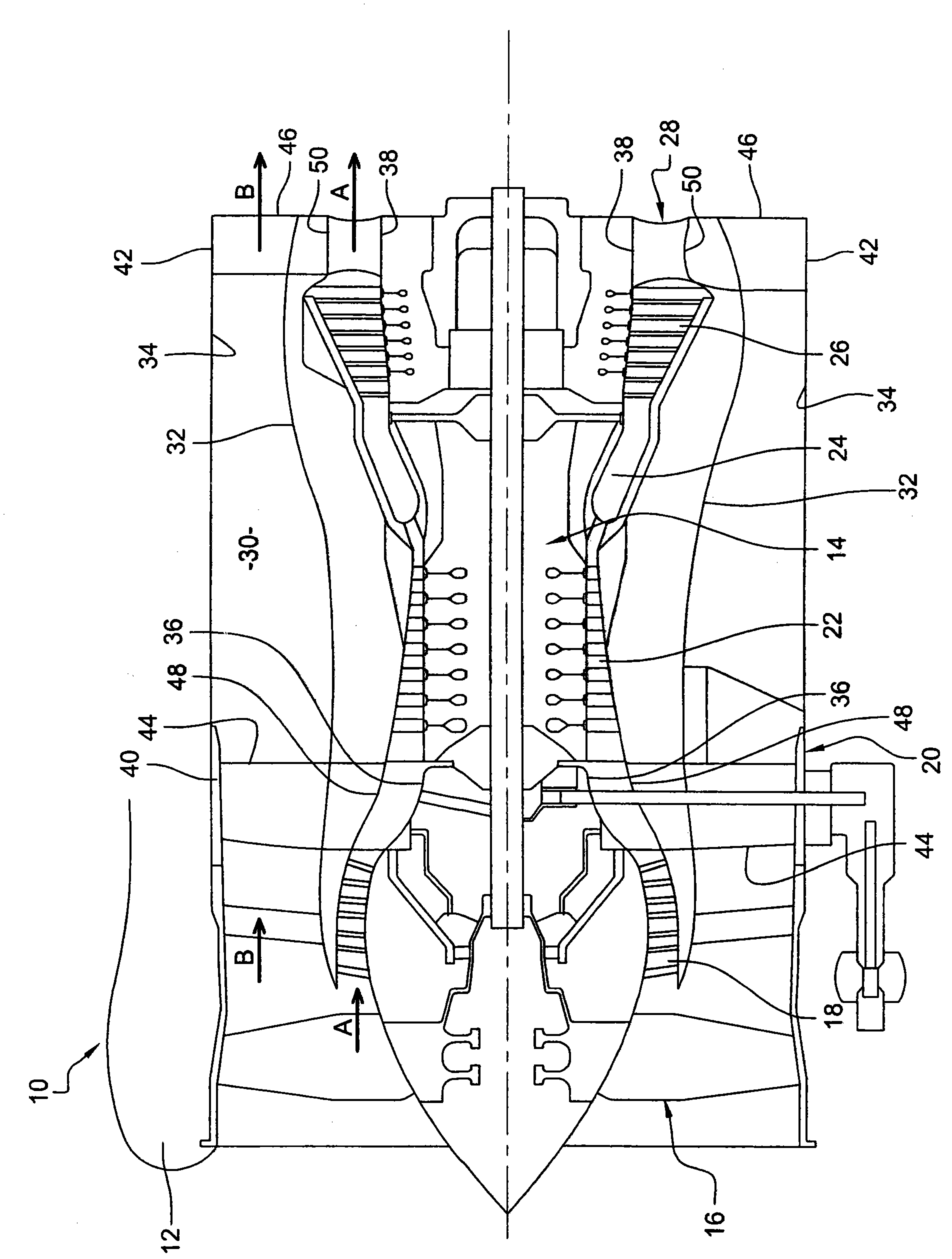

[0027] figure 1 Shown is a bypass turbine 10 comprising: a cylindrical cowl 12 surrounding a turbojet 14; and a fan wheel 16 mounted upstream of the turbojet 14, said turbojet from upstream to downstream mainly comprising: low pressure compression engine 18 , intermediate frame 20 , high pressure compressor 22 , combustor 24 , turbine 26 and discharge frame 28 .

[0028] In operation, the fan wheel 16 driven by the turbine 26 draws in an airflow which is divided into: the main airflow (arrow A) passing through the turbojet engine 14; A secondary airflow (arrow B) flowing aft of and around the engine 14 .

[0029] The fan duct 30 is formed from two coaxial generally cylindrical walls (an inner wall 32 and an outer wall 34 , respectively).

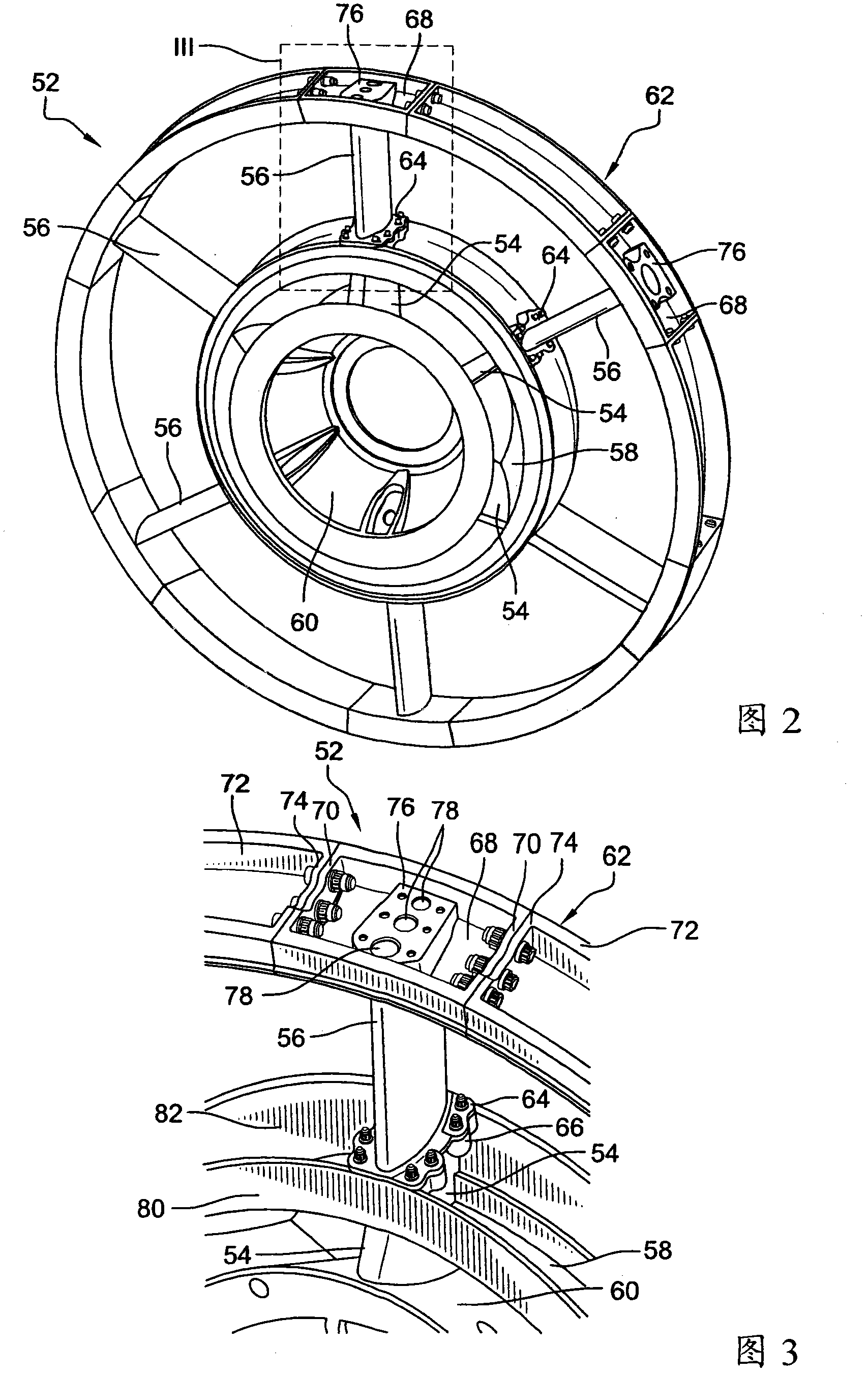

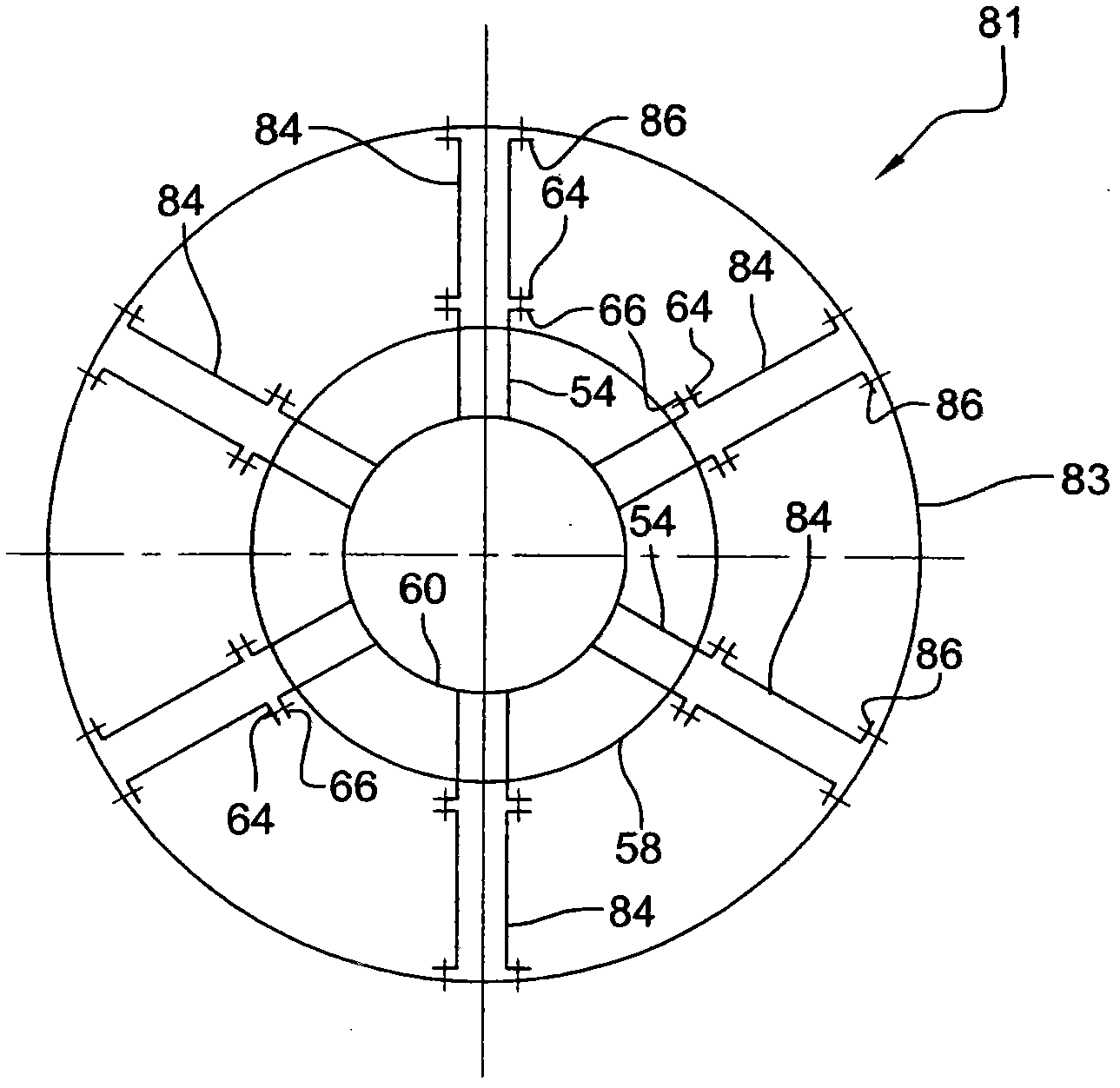

[0030] Intermediate frame 20 and discharge frame 28 are structural frames used to stiffen the turbine to limit deformation during operation. Both the intermediate frame 20 and the discharge frame 28 include pairs of coaxial rings, inner r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com