Process for increasing sulfur recovery rate in steel smelting

A technology of iron and steel smelting and sulfur element, which is applied in the technical field of improving the recovery rate of sulfur element in iron and steel smelting, which can solve the problems such as the reduction of sulfur element recovery rate, and achieve the effect of improving the utilization rate of sulfur and controlling the oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

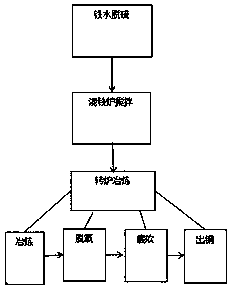

[0021] Example: such as figure 1 Shown: a process for improving the recovery rate of sulfur element in iron and steel smelting, comprising the following steps:

[0022] 1) Desulfurization of molten iron: desulfurize the molten iron, and then enter the mixed iron furnace after desulfurization;

[0023] 2) Stirring in the iron mixing furnace: the molten iron is evenly stirred in the iron mixing furnace, and then enters the converter for smelting;

[0024] 3) Converter smelting: The converter smelts, deoxidizes, and bottom blows the molten iron, and then taps the steel.

[0025] In this embodiment, in step 2), the stirring is sufficient, the molten iron and impurities should be visibly separated, and the temperature of the molten iron in the mixing furnace is 1300°C. The purpose of sufficient stirring is to promote the separation of molten iron and impurities. The molten iron is separated from slag in the iron mixing furnace. The average temperature in the iron furnace should ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com