n-tio2/c and n-tio2 and preparation method thereof

A titanium oxide and nitrogen doping technology is applied in the preparation of titanium dioxide nanomaterials, the preparation of nitrogen-doped titanium oxide (N-TiO2), and the field of nitrogen-doped titanium oxide/carbon nanocomposites, which can solve the problem of different reaction conditions. Mild, relatively high requirements for experimental conditions, to achieve the effects of low cost, high safety factor, and high nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

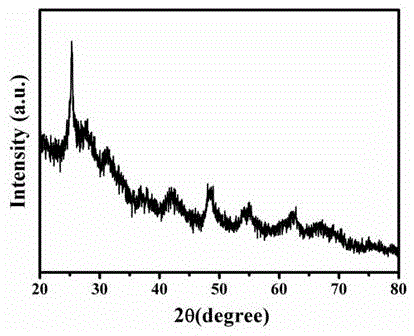

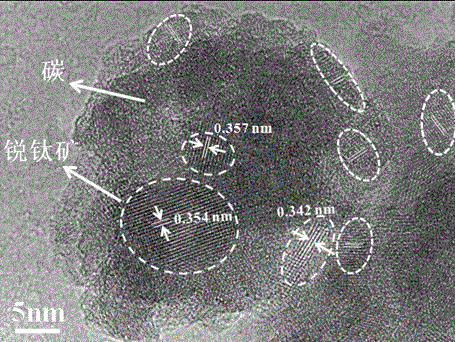

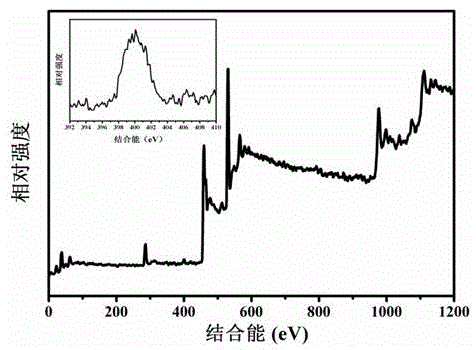

[0026] a kind of like Figure 1 to Figure 4 The shown nitrogen-doped titanium oxide / carbon nanocomposite is prepared by the following method:

[0027] 1) Add 10 mL of tetramethylammonium hydroxide solution into 30 mL of ethylene glycol and stir for 10 min, then add 1 mL of titanium isopropoxide, and stir for 0.5 h at room temperature to obtain a uniform solution.

[0028] 2) Transfer the homogeneous solution obtained in step 1) into a polytetrafluoroethylene with a volume of 80mL

[0029] In the inner lining of the hydrothermal kettle, after sealing it with a stainless steel jacket, it was hydrothermally reacted at 200 ° C for 8 hours, and it automatically

[0030] Then cool to room temperature.

[0031] 3) Use acetone, alcohol and deionized water to centrifuge and wash once respectively the obtained in step 2).

[0032] The reaction product was dried in air at 70°C for 10 hours.

[0033] 4) heat-treating the dried product obtained in step 3). The heat treatment temperatu...

Embodiment 2

[0041] A nitrogen-doped titanium oxide / carbon nanocomposite is prepared by the following method:

[0042] 1) Add 10 mL of tetramethylammonium hydroxide solution into 30 mL of ethylene glycol and stir for 10 min, then add 1 mL of titanium isopropoxide, and stir for 0.5 h at room temperature to obtain a uniform solution.

[0043] 2) Transfer the homogeneous solution obtained in step 1) into a polytetrafluoroethylene with a volume of 80mL

[0044] In the inner lining of the hydrothermal kettle, after sealing it with a stainless steel jacket, it was hydrothermally reacted at 200 ° C for 8 hours, and it automatically

[0045] Then cool to room temperature.

[0046] 3) Use acetone, alcohol and deionized water to centrifuge and wash once respectively the obtained in step 2).

[0047] The reaction product was dried in air at 70°C for 10 hours.

[0048] 4) heat-treating the dried product obtained in step 3). The heat treatment temperature is 350°C, the heat

[0049] The treatment ti...

Embodiment 3

[0052] a kind of like Figure 5 to Figure 8 The nitrogen-doped titanium oxide shown was prepared by the following method:

[0053] 1) Add 10 mL of tetramethylammonium hydroxide solution into 30 mL of ethylene glycol and stir for 10 min, then add 1 mL of titanium isopropoxide, and stir for 0.5 h at room temperature to obtain a uniform solution.

[0054] 2) Transfer the homogeneous solution obtained in step 1) into a polytetrafluoroethylene with a volume of 80mL

[0055] In the inner lining of the hydrothermal kettle, after sealing it with a stainless steel jacket, it was hydrothermally reacted at 200 ° C for 8 hours, and it automatically

[0056] Then cool to room temperature.

[0057] 3) Use acetone, alcohol and deionized water to centrifuge and wash once respectively the obtained in step 2).

[0058] The reaction product was dried in air at 70°C for 10 hours.

[0059] 4) heat-treating the dried product obtained in step 3). The heat treatment temperature is 450°C, the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com