Liquid-state alkane back flow method for preparing nanometer tungsten carbide

A liquid alkane and nanotechnology, applied in the direction of carbides, tungsten/molybdenum carbides, etc., can solve the problems of difficult carbon encapsulation, large shrinkage, high cost, etc., and achieve simple recovery and purification regeneration equipment, simple heat treatment equipment, and easy industrialization The effect of homework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

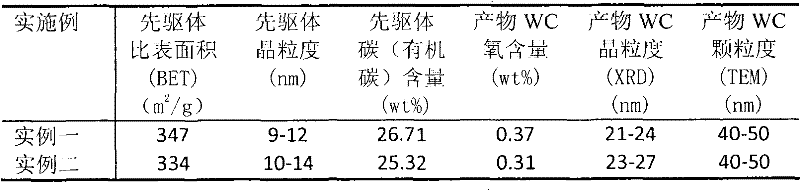

example 1

[0031] (1) raw materials: liquid alkane mixture (C 11 -C 16 )5000ml, absolute ethanol 5000ml, hydrated WO 3 About 50g.

[0032] (2) Reflux: 50g hydrated WO 3 Reflux with 500ml of absolute ethanol at 70°C for one hour, then filter; mix the obtained precipitate with fresh 500ml of absolute ethanol, and reflux at 70°C for one hour again, repeat the above reflux process 5 times; then filter the obtained The precipitate and 500ml liquid alkane mixture (C 11 -C 16 ) first reflux at 120°C for 48 hours, then filter the powder, repeatedly extract the ethanol in the alkane filtrate with distilled water, and then add an appropriate amount of anhydrous CaCl to the filtrate 2 Remove the remaining water to obtain a reusable alkane mixture, mix the regenerated liquid alkane mixture with the filtered powder and reflux at 150°C for 48 hours, use the same method as above to obtain a recycled alkane mixture, and then Reflux at 180°C and 210°C for 48 hours respectively, and finally filter o...

example 2

[0038] (1) raw materials: liquid alkane mixture (C 11 -C 16 )5000ml, absolute ethanol 5000ml, hydrated WO 3 About 80g.

[0039] (2) Reflux: 80g hydrated WO 3 Reflux with 500ml of absolute ethanol at 85°C for one hour, and then filter; the obtained precipitate is mixed with fresh 500ml of absolute ethanol, and reflux at 85°C for one hour again, and the above reflux process is repeated 5 times; then filter the obtained The precipitate and 500ml liquid alkane mixture (C 11 -C 16 ) first reflux at 120°C for 24 hours, then filter the powder, repeatedly extract the ethanol in the alkane filtrate with distilled water, and then add an appropriate amount of anhydrous CaCl to the filtrate 2 Remove the remaining water to obtain a reusable alkane mixture, mix the regenerated liquid alkane mixture with the filtered powder and reflux at 150°C for 48 hours, use the same method as above to obtain a recycled alkane mixture, and then Reflux at 180° C. and 210° C. for 48 hours respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| surface | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com