Method and device for vacuum hot dip aluminum or aluminum alloy plating for metal workpiece

A metal workpiece, hot-dip aluminum plating technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problems affecting surface quality and corrosion resistance, can not stop production at any time, high process requirements, achieve Avoid surface oxidation problems, increase interface bonding force, and improve the effect of coating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below by way of examples.

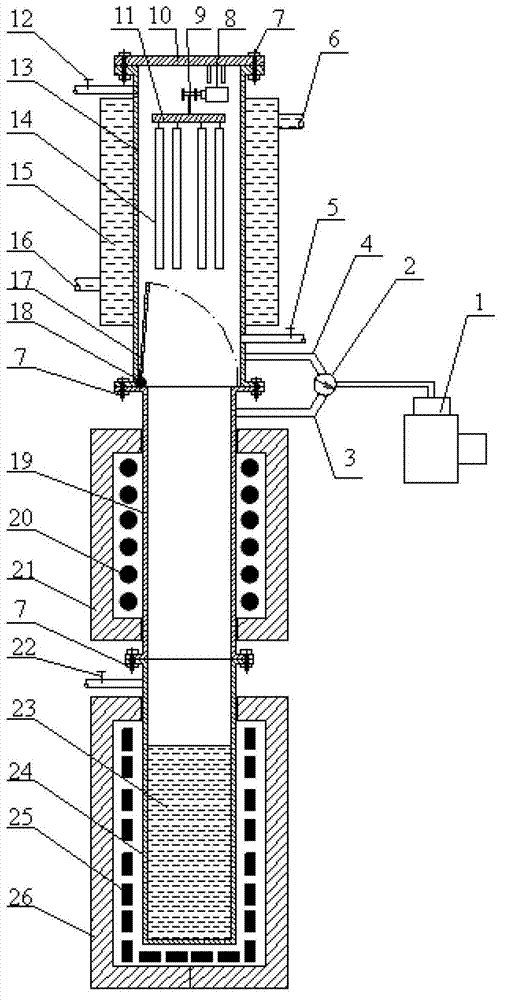

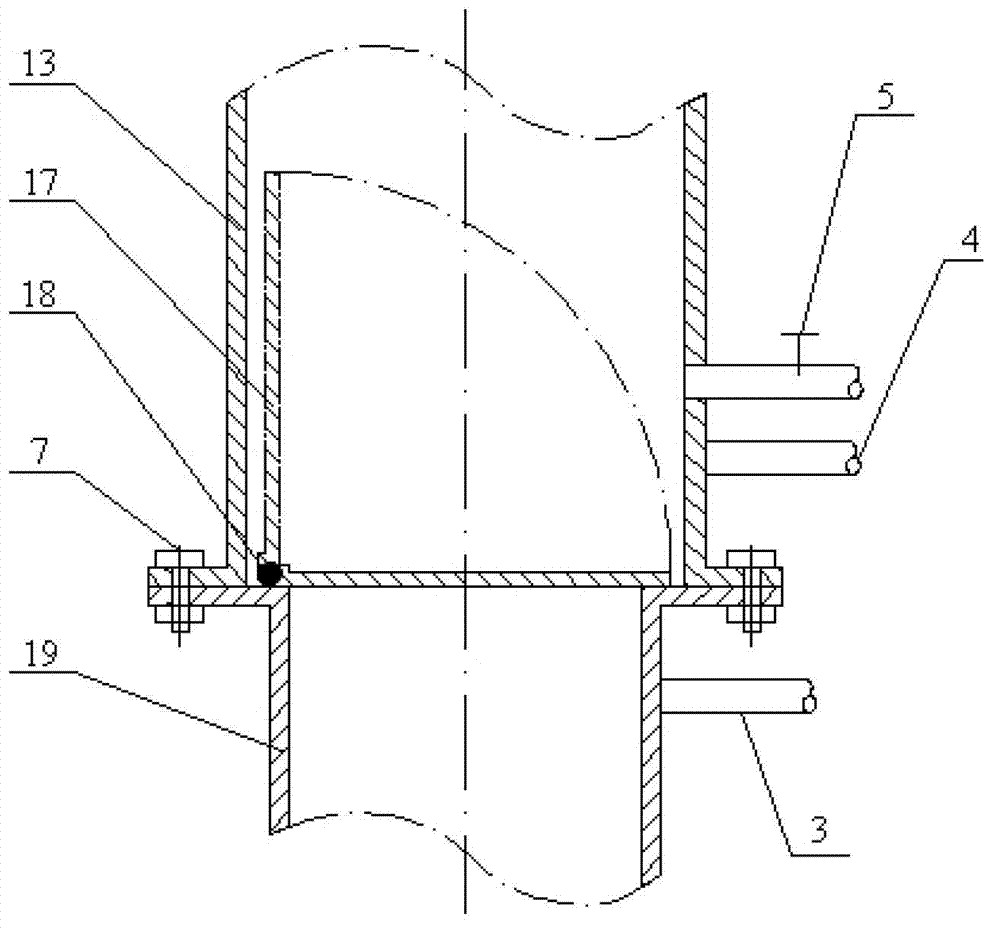

[0037] Such as figure 1 As shown, a vacuum hot-dip aluminum and aluminum alloy device for metal workpieces consists of a vacuum pump 1, a reversing valve 2, a reduction furnace exhaust pipe 3, a cooling furnace exhaust pipe 4, an air intake valve 5, a cooling water outlet 6, Connecting bolt 7, winch motor 8, steel wire rope 9, feeding mechanism 10, material pan 11, upper exhaust valve 12, cooling furnace 13, cooling wall 15, cooling water inlet 16, sealing valve cover 17, driving shaft 18, reduction Furnace 19, heating element 20, reduction furnace insulation layer 21, lower exhaust valve 22, molten aluminum liquid 23, aluminum melting furnace 24, heater 25 and aluminum melting furnace insulation layer 26.

[0038] Using the device, the hot-rolled plain carbon steel seamless steel pipe (hereinafter referred to as the steel pipe) is used as a metal workpiece to be reduced and then vacuum hot-dip al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com