A kind of preparation method of carbon-coated Li4Ti5O12 nanometer negative electrode material

A negative electrode material, carbon coating technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of equipment corrosion, chloride recycling, uneven mixing, cumbersome preparation process, etc., and achieve good high-rate charge and discharge performance , uniform mixing of materials, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

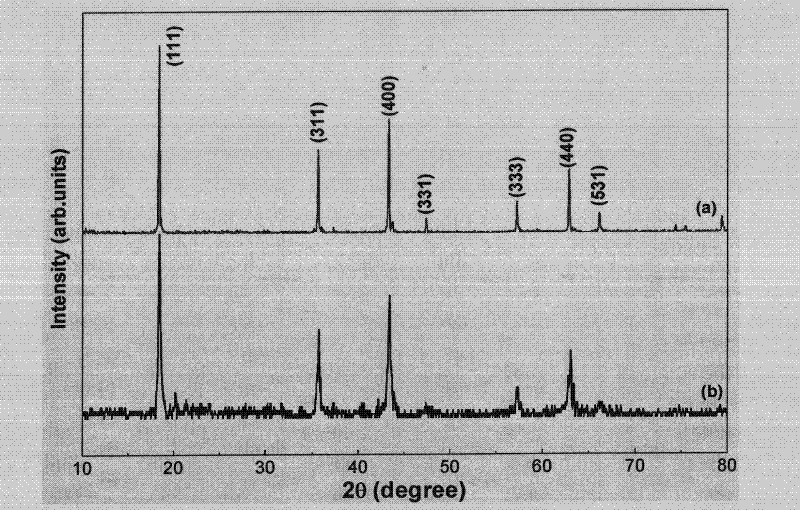

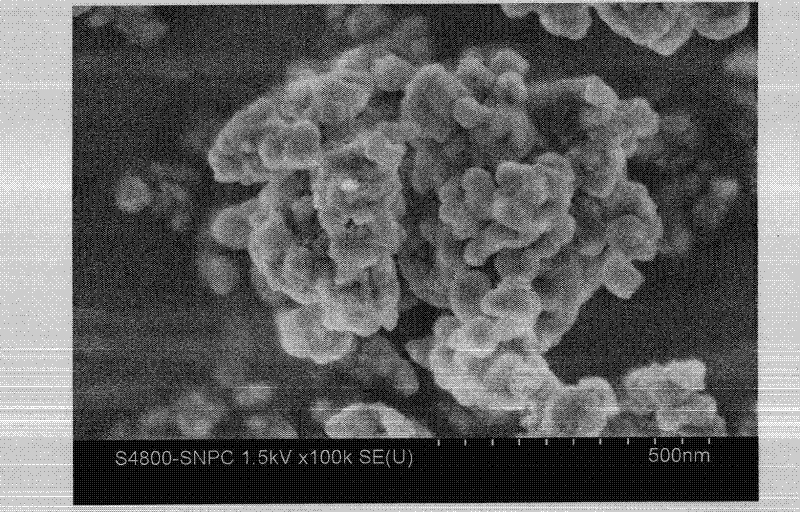

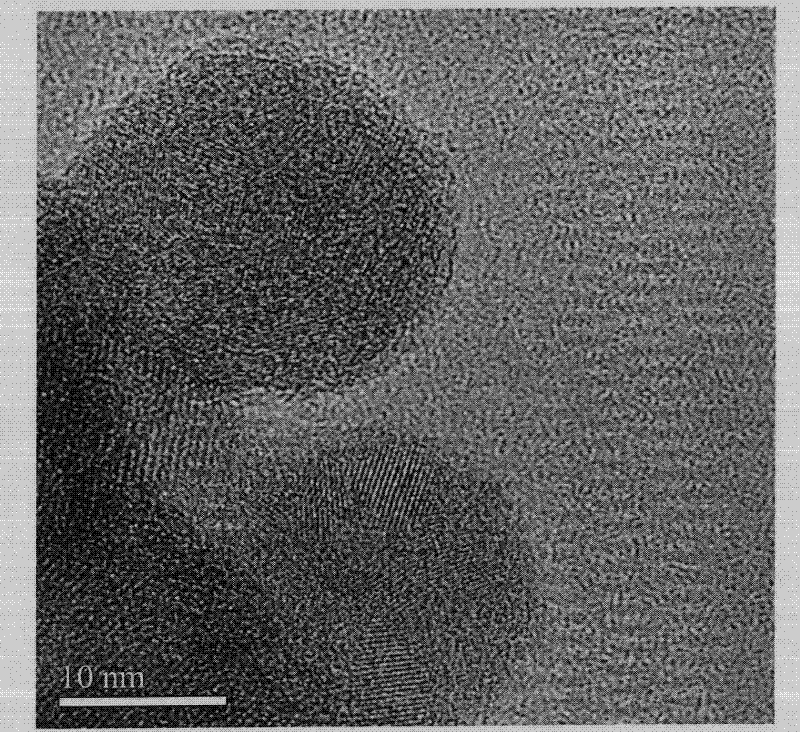

[0029]Weigh 1.47g lithium citrate, 0.78g lithium carbonate and 4g anatase TiO 2 , add 5ml of deionized water, put the three into a ball mill jar and mill for 2h, after drying, sinter at 800°C for 12h, and then naturally cool to room temperature to obtain carbon-coated Li 4 Ti 5 o 12 Nano anode material. It is measured that the carbon content in the carbon-coated lithium titanate material is 6.7%, the average particle size of the particles is 30nm, and the specific surface area is 50.7m 2 / g, the first discharge specific capacity is 121.1mAh / g at 20C, and it is 106.1mAh / g after 100 cycles.

Embodiment 2

[0031] Weigh 2.21g lithium citrate, 0.39g lithium carbonate and 4g anatase TiO 2 , add 5ml of deionized water, put the three into a ball mill jar and mill for 2h, after drying, sinter at 800°C for 12h, and then naturally cool to room temperature to obtain carbon-coated Li 4 Ti 5 o 12 Nano anode material. It is measured that the carbon content in the carbon-coated lithium titanate material is 8.0%, the average particle size of the particles is 25nm, and the specific surface area is 80.2m 2 / g, the first discharge specific capacity is 110.5mAh / g at 20C, and it is 82.6mAh / g after 100 cycles.

Embodiment 3

[0033] Weigh 1.34g butyllithium, 0.78g lithium carbonate and 4g anatase TiO 2 , add 5ml of deionized water, put the three into a ball mill jar and mill for 2h, after drying, sinter at 800°C for 12h, and then naturally cool to room temperature to obtain carbon-coated Li 4 Ti 5 o 12 Nano anode material. It is measured that the carbon content in the carbon-coated lithium titanate material is 4.0%, the average particle size of the particles is 60nm, and the specific surface area is 36.7m 2 / g, the first discharge specific capacity is 98.2mAh / g at 20C, and it is 43.5mAh / g after 100 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com