Method for preparing carbon-coated lithium iron phosphate anode material of lithium ion battery

A carbon-coated lithium iron phosphate and lithium-ion battery technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of reducing the content of active materials and reducing the overall capacity, and achieves excellent cycle performance and excellent super-large rate performance , the effect of excellent size magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

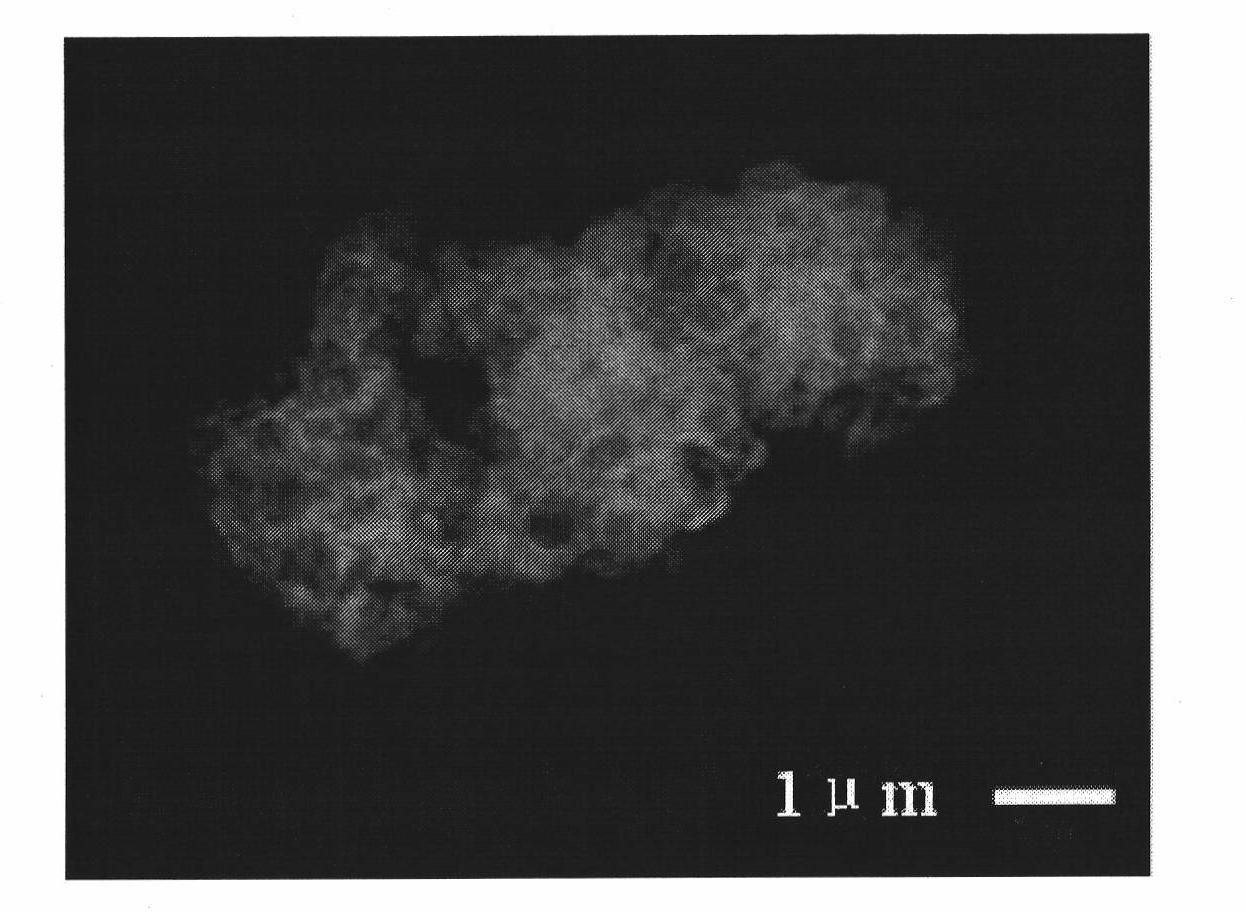

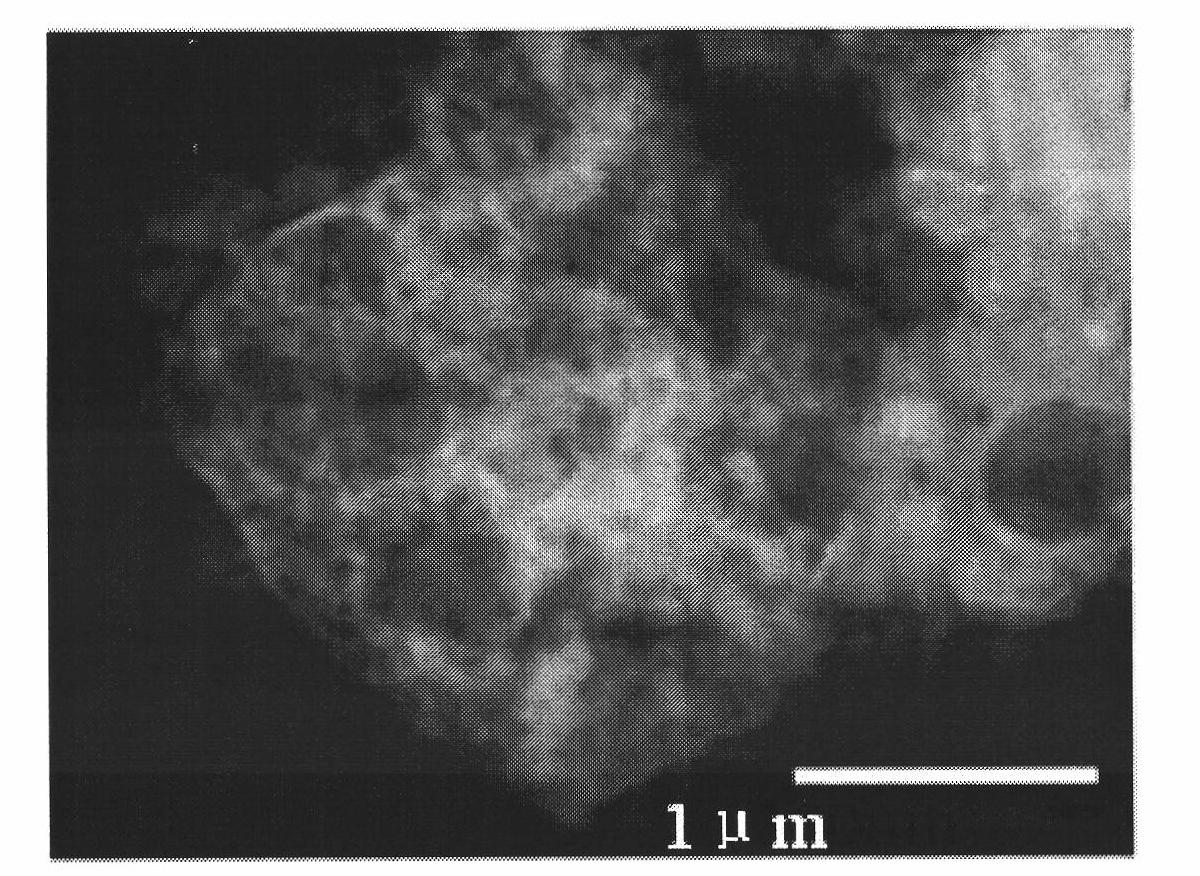

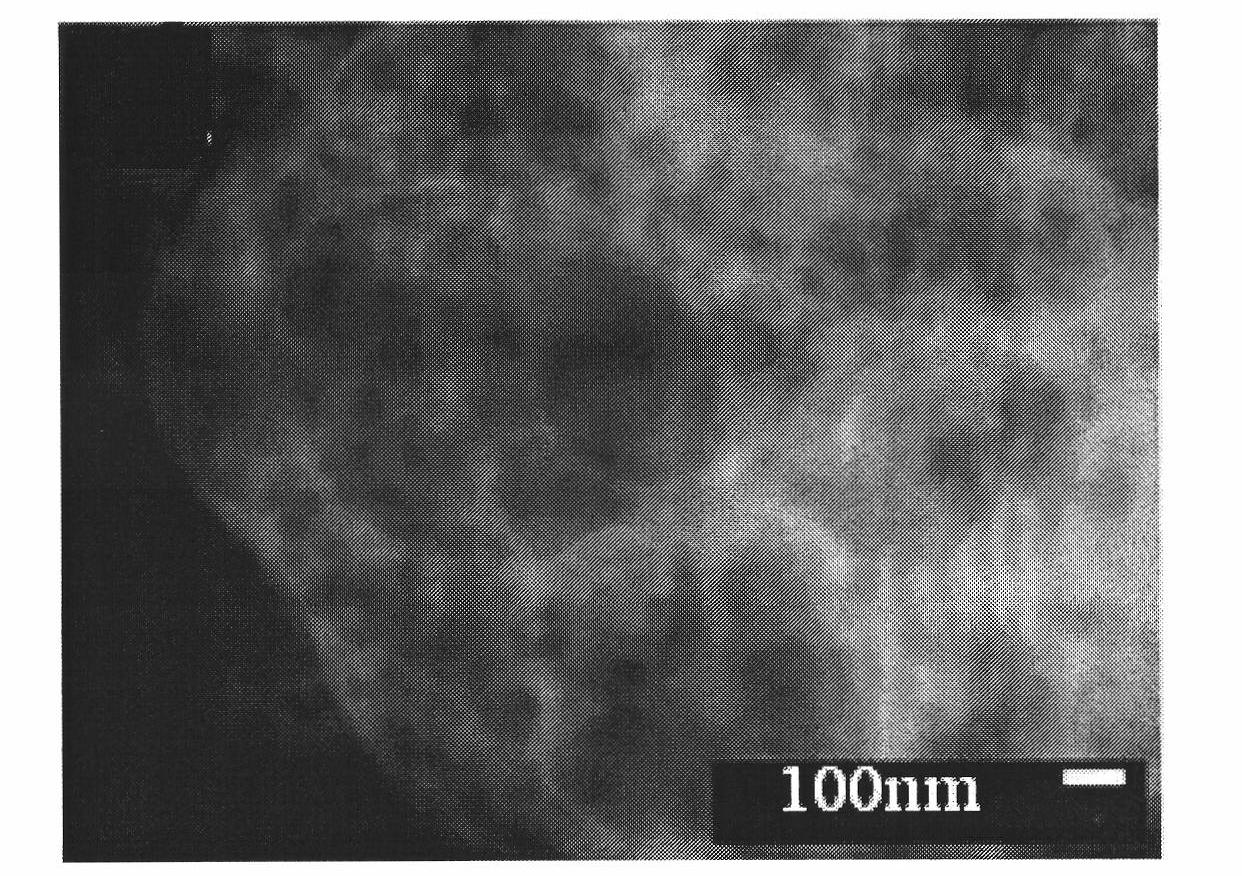

Embodiment 1

[0035] 1.039g LiH 2 PO 4 , 4.041gFe(NO 3 ) 3 9H 2 O, 6.3g of citric acid monohydrate, 1.6g of ethylene glycol, and 3.2g of ammonium nitrate were dissolved in water to form a sol, heated and evaporated to dryness to form a gel, and then the gel was ignited and burned to obtain an intermediate. Figure 1-Figure 3 It is the SEM picture of the intermediate body, it can be seen that the intermediate body is highly porous sponge, its particle size is about 10nm, and the diameter of the hole is about 500nm. After the intermediate was mixed with 0.4g glucose and 8g acetone ball milled for 8h, the 2 , and calcined at 700°C for 8 hours to obtain carbon-coated lithium iron phosphate. Figure 4 with Figure 5 The SEM and TEM images of the carbon-coated lithium iron phosphate obtained in this example respectively show that the particle size of the carbon-coated lithium iron phosphate synthesized by the sol-gel-combustion method under this condition is in the range of submicron and mi...

Embodiment 2

[0038] 0.689gLiNO 3 , 4.041gFe(NO 3 ) 3 9H 2 O, 1.15gNH 4 h 2 PO 4 , 4.2g citric acid monohydrate, 9.48g ethylene glycol, and 3.2g ammonium nitrate were dissolved in water to form a sol, heated and evaporated to dryness to form a gel. Then ignite and burn the gel to obtain the intermediate. After the intermediate was mixed with 0.16g sucrose and 3.16g ethanol ball milled for 10h, in H 2 10% N 2 / H 2 Calcined at 850°C for 1 h in a mixed gas to obtain carbon-coated lithium iron phosphate.

Embodiment 3

[0040]1.039g LiH 2 PO 4 , 1.268gFeCl 2 , 21g citric acid monohydrate, 8.0g ethylene glycol, and 12.64g ammonium nitrate were dissolved in water to form a sol, heated and evaporated to dryness to form a gel. Then ignite and burn the gel to obtain the intermediate. After the intermediate was mixed with 0.8g glucose and 31.6g acetone ball milled for 6h, it was mixed in H 2 5% Ar / H 2 Calcined at 550°C for 24 hours in a mixed gas to obtain carbon-coated lithium iron phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com