Bainite steel plate with high elongation, high strength and low carbon and production method thereof

A low-carbon bainite and carbon bainite steel technology, applied in the direction of temperature control, furnace type, furnace, etc., can solve the problems of low elongation, forming influence, poor plasticity, etc., achieve high elongation, improve life, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

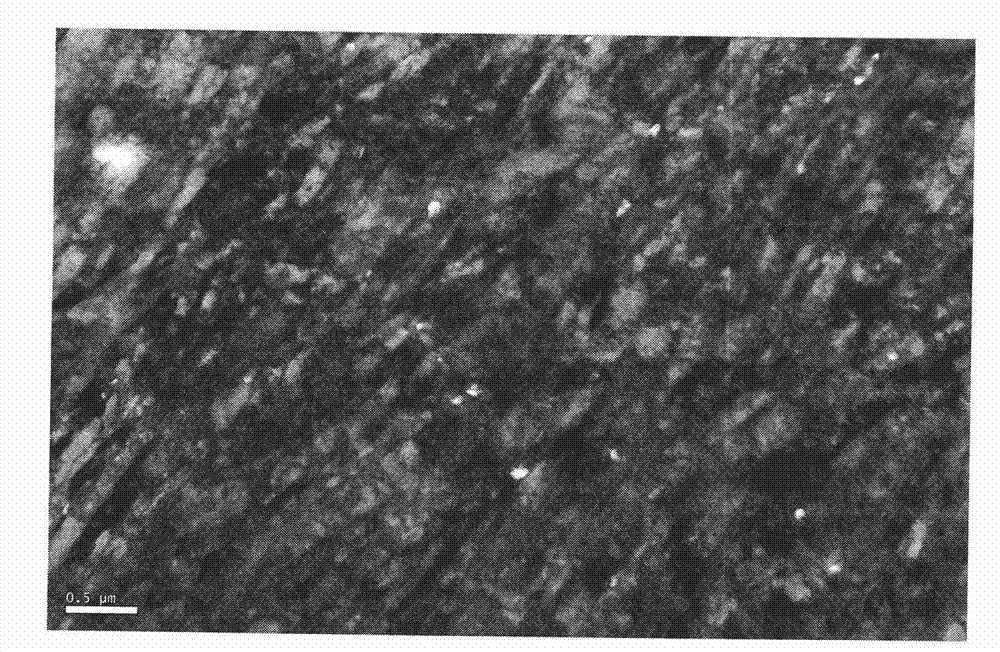

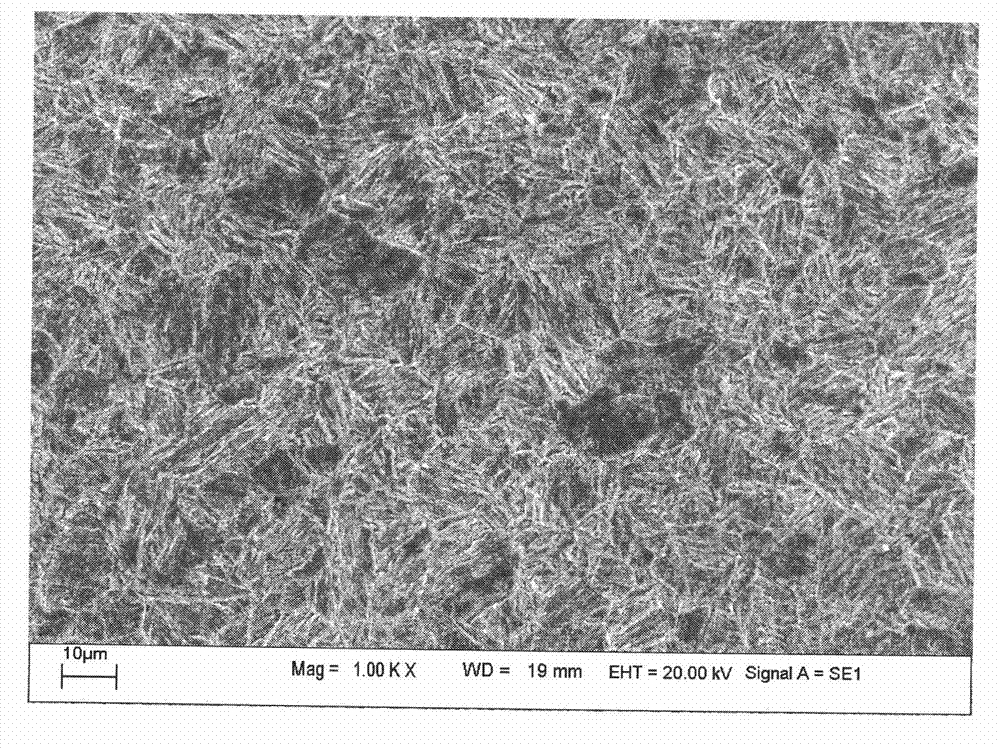

Embodiment 1

[0031] According to the mass percentage of chemical composition C: 0.075%, Si: 0.55%, Mn: 1.7%, P: 0.0069%, S: 0.005%, Cr: 0.4%, Mo: 0.37%, Cu: 0.8%, Nb: 0.06%, Ti: 0.02%, B: 0.0015%, Ni: 0.79%, V: 0.036%, molten steel is smelted in a vacuum electromagnetic induction furnace, and cast into a steel ingot, the thickness of the steel ingot is 70mm, the steel billet is heated to 1230 ° C, and kept for 2 hours, Rolling is carried out on a two-roll mill, the starting temperature is 1160°C, the final rolling is at 1050°C, the cumulative reduction rate is 62%, and then the second stage rolling is started when the temperature reaches 950°C, the final rolling temperature is 800°C, The thickness of the plate after rolling is 10mm. After the temperature reaches 780°C, it is quenched to 300°C, air-cooled to room temperature; then heated to 930°C and kept for 45 minutes, and then quenched to room temperature. After tempering at 650°C for 1 hour, water-cooled to room temperature, then temper...

Embodiment 2

[0033]According to the mass percentage of chemical composition C: 0.18%, Si: 1.55%, Mn: 1.13%, P: 0.0059%, S: 0.005%, Cr: 0.40%, Mo: 0.35%, Cu: 0.30%, Nb: 0.059%, Ti: 0.15%, B: 0.001%, Ni: 0.76%, V: 0.05%. Melt molten steel in a vacuum electromagnetic induction furnace and cast it into a steel ingot. The thickness of the steel ingot is 70mm. Two-stage rolling is carried out on the two-roll mill, the starting temperature is 1130°C, the final rolling temperature of the first stage is 1050°C, and the cumulative reduction rate is 62%, the second stage rolling starts when the temperature reaches 950°C, and the final rolling temperature The temperature is 810°C, the cumulative reduction rate is greater than 60%, and the thickness of the rolled plate is 10mm. Wait until the temperature reaches 760°C, then quench to 280°C, then air cool to room temperature; heat up to 960°C and keep for 45 minutes, then quench to room temperature. After heating to 630°C and tempering for 1 hour, wate...

Embodiment 3

[0035] According to the mass percentage of chemical composition C: 0.15%, Si: 1.0%, Mn: 1.3%, P: 0.004%, S: 0.003%, Cr: 0.36%, Mo: 0.4%, Cu: 0.30%, Nb: 0.04%, Ti: 0.20%, B: 0.0015%, Ni: 0.7%, V: 0.05%, molten steel is smelted in a vacuum electromagnetic induction furnace, and cast into a steel ingot, the thickness of the steel ingot is 70mm, and the steel billet is heated to 1200°C for 2 hours. Two-stage rolling is carried out on the two-roll mill, the starting temperature is 1160°C, the final rolling temperature of the first stage is 1040°C, and the cumulative reduction rate is 62%. The second stage rolling starts when the temperature reaches 950°C, and the final rolling temperature The temperature is 820°C, the cumulative reduction rate is greater than 60%, and the thickness of the rolled plate is 10mm. Wait until the temperature reaches 780°C, then quench to 280°C, air cool to room temperature; raise the temperature to 940°C and keep it for 45 minutes, then quench to room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com