Half-W-shaped flame burning supercritical power station boiler

A power plant boiler, flame combustion technology, applied in the direction of combustion method, combustion type, combustion equipment, etc., can solve the problem of poor stable combustion performance under low load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

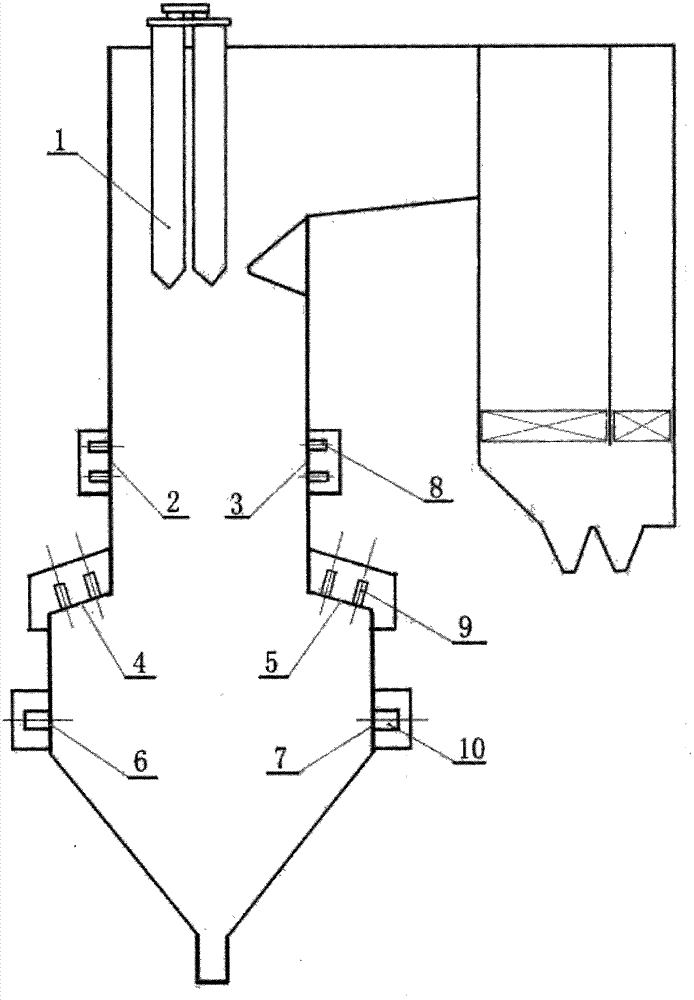

[0032] Combine now figure 1 Taking a 1000MW level, once-reheated Π-type supercritical utility boiler with a design value of main steam temperature / reheated steam temperature of 605°C / 613°C as an example, the optimal way of realizing the invention is illustrated.

[0033] The semi-"W" flame combustion supercritical power plant boiler of the present invention includes a lower furnace with a front arch and a rear arch; two rows of weak swirl burners are respectively arranged on the front arch of the lower furnace and the rear arch of the lower furnace; each row consists of 8 burners Composed of weak swirl burners, uniformly distributed along the furnace width; each row of weak swirl burners is connected with a double-inlet and double-outlet steel ball mill; one row is arranged at the lower part of the front wall of the lower furnace and the rear wall of the lower furnace Double air-regulating swirl burners; each column is composed of 8 double-air swirling burners, which are evenl...

Embodiment 2

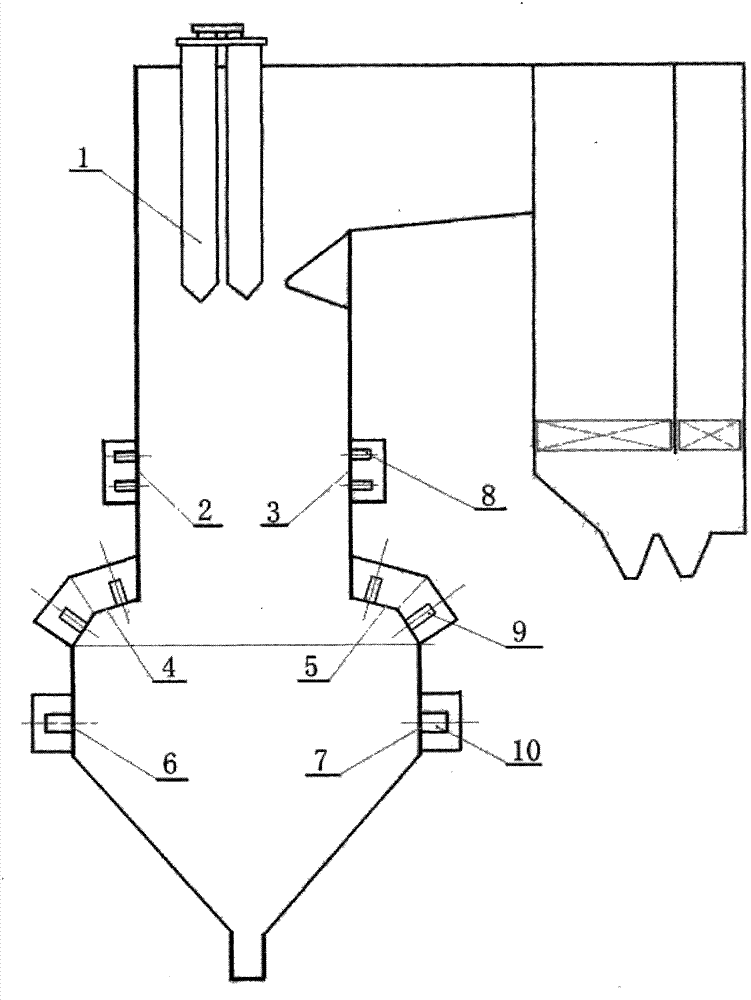

[0035] Combine now figure 2 Taking a 1000MW level, once-reheated Π-type supercritical utility boiler with a design value of main steam temperature / reheated steam temperature of 605°C / 613°C as an example, the optimal way of realizing the invention is illustrated.

[0036] The semi-"W" flame combustion supercritical power plant boiler of the present invention includes a lower furnace with a front arch and a rear arch; two rows of weak swirl burners are respectively arranged on the front arch of the lower furnace and the rear arch of the lower furnace; each row consists of 8 burners Composed of weak swirl burners, uniformly distributed along the furnace width; each row of weak swirl burners is connected with a double-inlet and double-outlet steel ball mill; one row is arranged at the lower part of the front wall of the lower furnace and the rear wall of the lower furnace Double air-regulating swirl burners; each column is composed of 8 double-air swirling burners, which are even...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com