Hot-rolled 430 ferrite antibacterial stainless steel and preparation method thereof

An antibacterial stainless steel and ferrite technology, applied in the field of metal materials, can solve the problems of high production cost and long process flow, and achieve the effect of reducing the deterioration of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The composition of table 3 embodiment 1 copper-containing antibacterial stainless steel:

[0026]

[0027] Hot rolling process:

[0028] Heat to 1250°C for 2 hours, start rolling at 1100°C, hot-roll to 4mm, and finish rolling at 900°C.

[0029] Antibacterial annealing process:

[0030] 800℃×0.5h

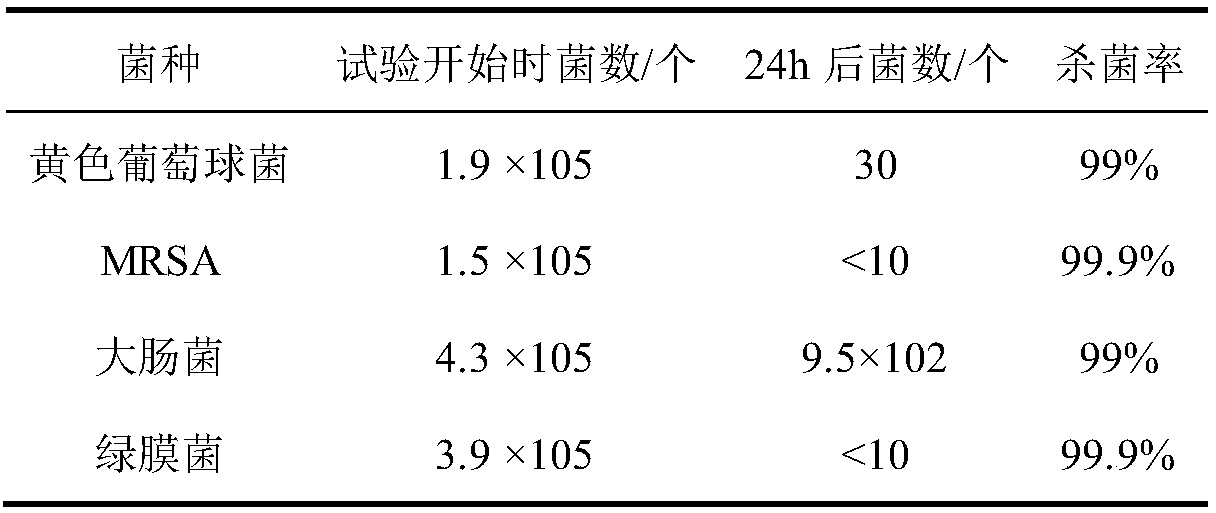

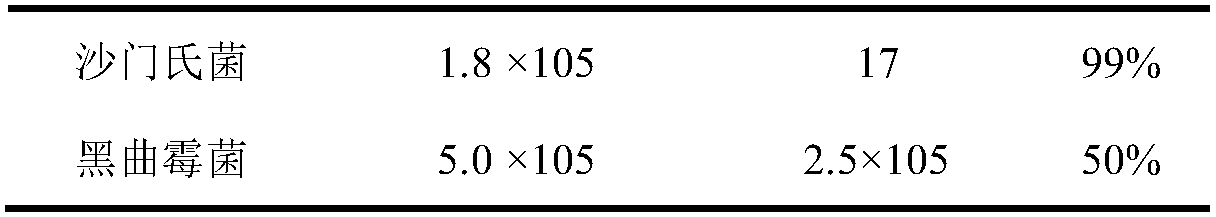

[0031] After testing by the antibacterial material testing center of the Institute of Physical and Chemical Technology, Chinese Academy of Sciences, the antibacterial rate of the hot-rolled 430 ferritic antibacterial stainless steel manufactured according to the invention reaches 99.9% against Escherichia coli and 99.9% against Staphylococcus aureus.

[0032] Table 4 is the difference of copper content, the different embodiment list of antibacterial annealing time

[0033] serial number

[0034] Wherein embodiment 2, 3 other compositions of antibacterial stainless steel and hot rolling process are identical with embodiment 1, just copper content and antibacteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com