Purifying treatment device and purifying treatment method for flue gas multicomponent pollutant generated by incinerating refuse

A technology for waste incineration and purification treatment, which is applied to combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of low removal rate, lag in outlet discharge regulation, and large limitations, and achieves improved bed density, enhanced Mass and heat transfer, easy to capture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

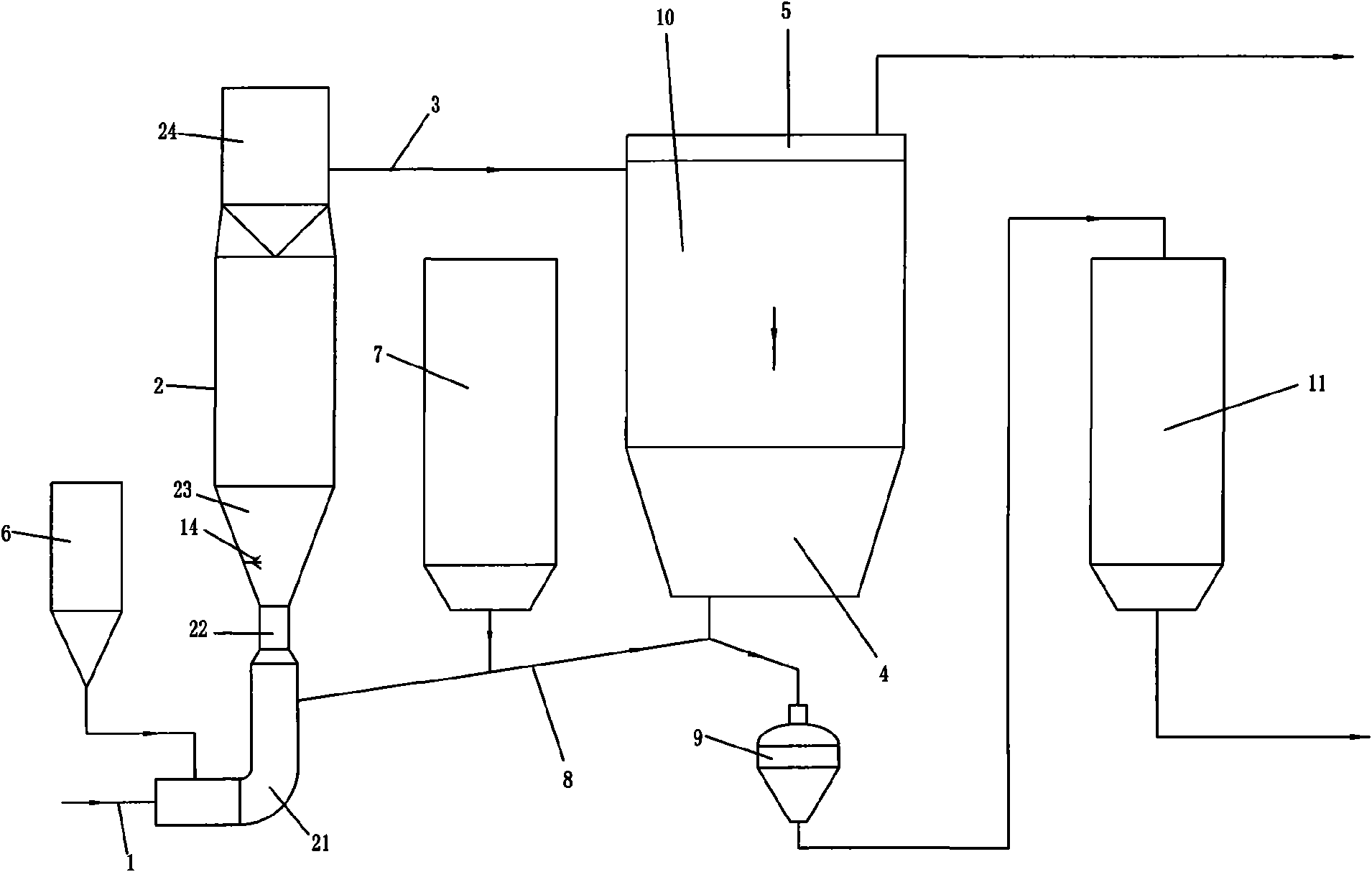

[0028] Flue gas parameters of waste incinerator: waste incinerator processing capacity: 100t / d, dust concentration: 13.36mg / Nm 3 , SO 2 Concentration 1450mg / Nm 3 , SO 3 Concentration 80mg / Nm 3 , dry standard flue gas volume: 15860Nm 3 / h, temperature: 140-180°C.

[0029]The flue gas (140-180°C) at the outlet of the waste incinerator enters the feed section 21 at the bottom of the circulating fluidized bed deacidification tower 2 from the inlet flue 1, and enters the circulating fluidized bed deacidification tower 2 from bottom to top, and waste incineration Furnace flue gas is first subjected to dioxin with the activated carbon fed into the circulating fluidized bed deacidification tower 2 from the activated carbon bin 6 and the circulating ash with fresh absorbent fed into the circulating fluidized bed deacidification tower 2 from the material circulation air chute 8. The adsorption of British and the removal of HCl and HF, the Ca / S molar ratio is controlled at 1.1 to 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com