Crude separation system and crude separation method for cumene method epoxidation products

A technology of propylene benzene method and epoxidation, which is applied in the direction of organic chemistry, etc., can solve the problem of difficult separation of the outlet of the epoxidation reactor, and achieve the effect of reducing the number of equipment, reducing the floor area, and reducing the weight of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

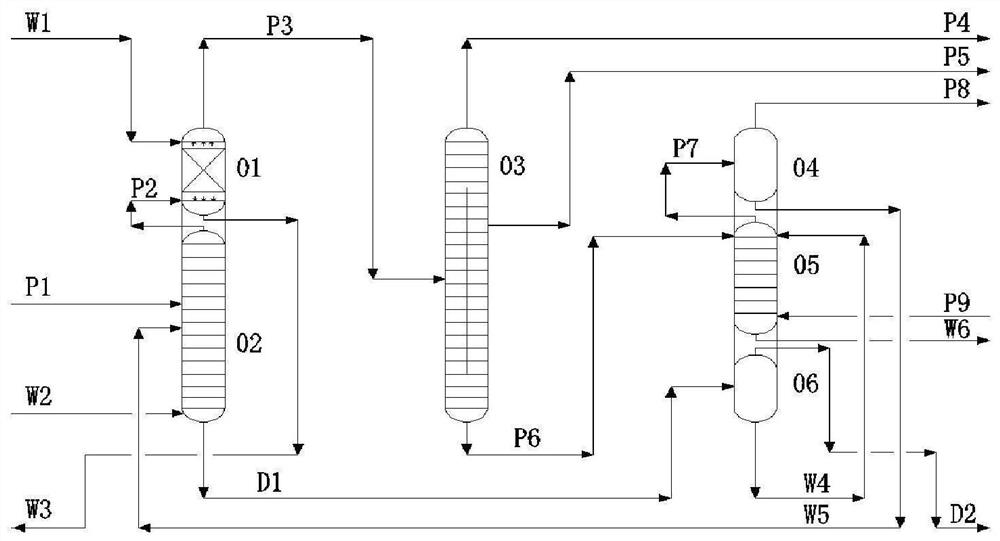

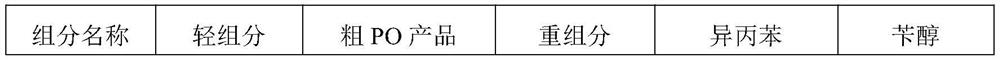

[0027]Be 50,000 tons / year CHPPO industrial production plant as example with the nominal capacity, set up a production line, adopt the crude separation system and separation method of cumene method epoxy product of the present invention, in crude PO rectification separation technological process, through Set up the process equipment of alkali washing tower 01, crude PO tower 02, dividing wall tower 03, flash tower 04, extraction tower 05, oil-water separation tower 06, among which, alkali washing tower 01 and crude PO tower 02 are combined up and down to form a stack tower; the flash tower 04, the extraction tower 05 and the oil-water separation tower 06 are merged into superimposed towers according to the upper, middle and lower parts; the middle part of the partition wall tower 03 is provided with a partition wall to prevent contact between the materials entering the tower and the materials exiting the tower, and the materials to be avoided are back-mixed; The PO tower injects...

Embodiment 2

[0039] The same as in Example 1, the nominal capacity is changed to 300,000 tons / year CHPPO commercial industrial production equipment, a production line is set up, and the equipment selection is modified as follows: Pall rings are used for the filler of alkali washing tower 01, and the specification of the Pall rings is 38mm, and the gas phase distribution The distributor adopts conical riser pipe distributor, and the liquid phase distributor adopts shower sprayer; the 02 tray of the coarse PO tower adopts the sieve tray, and the sieve hole specification is 8mm; Tray, sieve hole specification is 12mm; Extraction tower 05 adopts sieve tray tower; The composition of the reaction product P1 of this embodiment is shown in Table 2:

[0040] Table 2 Epoxidation reactor outlet reaction product composition list

[0041] component name light component Crude PO product heavy component Cumene Benzyl alcohol wt% 2.08 26.99 4.56 31.23 35.14

[0042] The ...

Embodiment 3

[0045] Same as Example 1, the nominal capacity is modified to 900,000 tons / year CHPPO large-scale commercial industrial production equipment, three production lines are set up, and the nominal capacity of each production line is 300,000 tons / year, and the equipment selection is modified as follows: alkali washing tower 01 The filler adopts a stepped ring, and the size of the stepped ring is 25mm. The gas phase distributor adopts a corrugated distributor, and the liquid phase distributor adopts a disc distributor; the 02 tray of the coarse PO tower adopts a guided valve tray, and the length of the slit in the tray is Partition wall is set in the middle part of partition tower 03 tower, and tray adopts guide valve tray, and the slot length in the tray is 36mm; Extraction tower 05 adopts concentric rotating disk tower; The composition of present embodiment reaction product P1 is as table 3:

[0046] Table 3 Epoxidation reactor outlet reaction product composition list

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com