Treatment process of oil-containing sewage in low-permeability oil field

A treatment process and technology for oily sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, mining wastewater treatment, etc. Pollution and other problems, to achieve the effect of chemical cleaning cycle and service life extension, easy on-site management, and reducing the degree of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

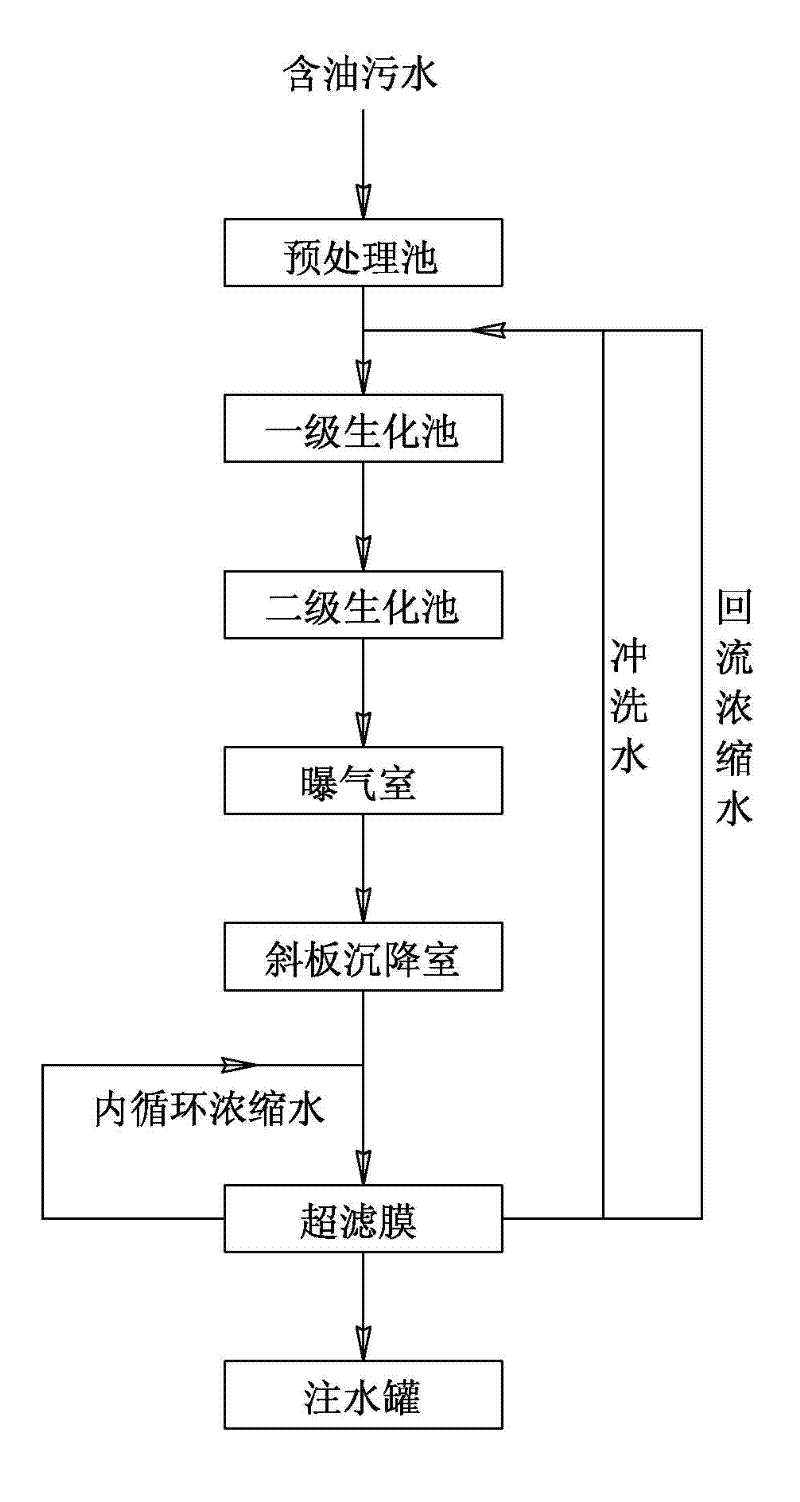

[0027] Such as figure 1 Shown is the flowchart of the present invention. Using a low-permeability oilfield oily sewage treatment process method of the present invention to carry out oily sewage treatment, the steps are as follows:

[0028] step 1)

[0029] Pretreatment: The oily sewage from the formation first enters the pretreatment tank, the oil content in the oily sewage is ≤300 mg / L, and the sulfide content is ≤50 mg / L. Air aeration devices are installed at the bottom of the pretreatment tank to The influent is aerated, the air-water ratio is 10:1, and the residence time is about 0.5h, so that the sulfides in the oily sewage are fully oxidized. The residence time can be appropriately extended, and the oily sewage with low sulfur content The residence time is short, and the oily sewage with high sulfur content stays for a long time; the purpose of pretreatment is to fully oxidize the reducing sulfide in the oily sewage, which can reduce the impact of sulfide and other red...

Embodiment 2

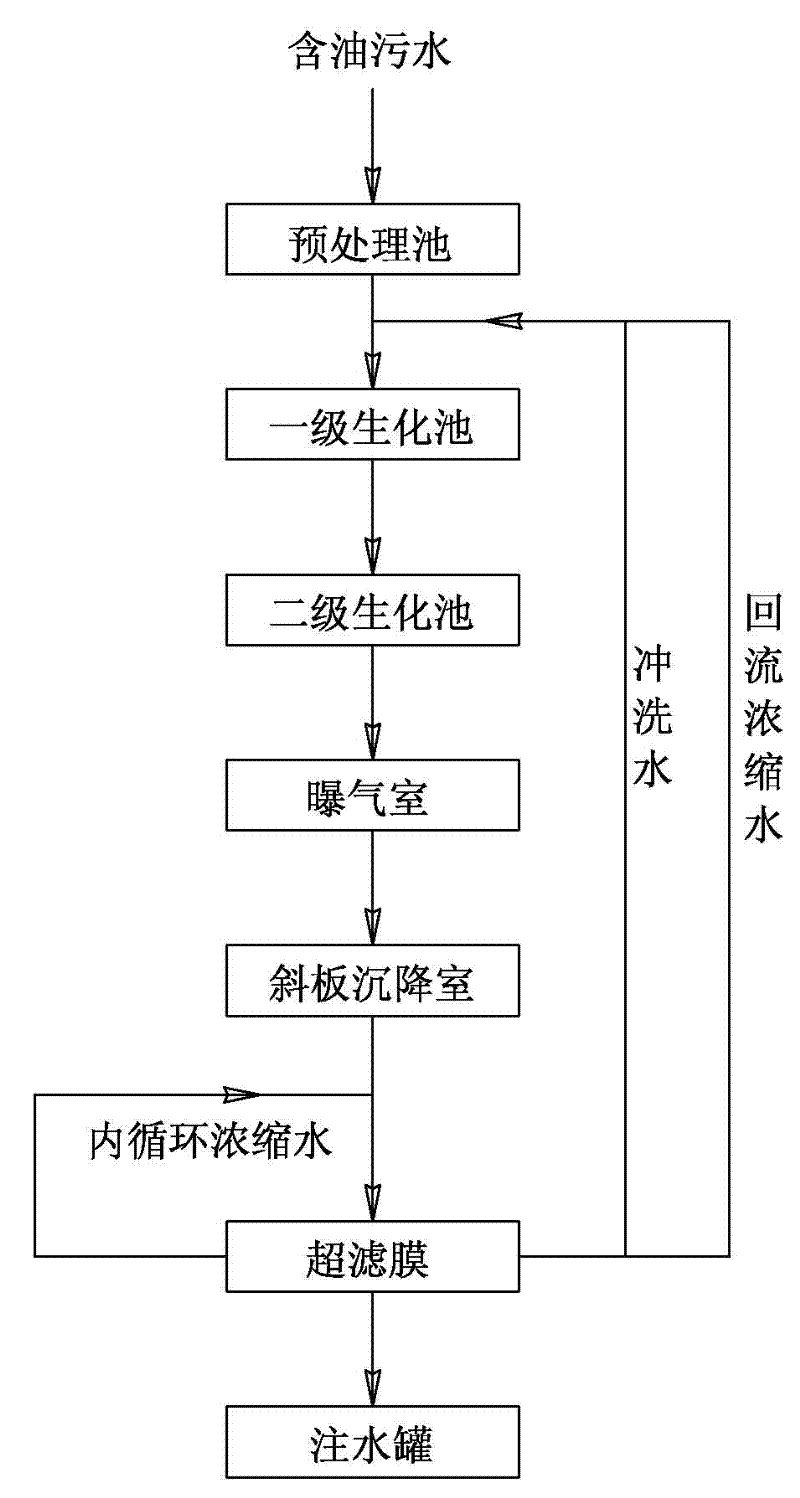

[0040] On-site application of a sewage treatment station in an oil field, with a daily sewage treatment volume of 500m 3 / d; Utilize the low-permeability oil field oily sewage treatment process method of the present invention, process according to the following steps:

[0041] step 1)

[0042] Pretreatment: The oily sewage from the formation first enters the pretreatment tank, and an air aeration device is installed at the bottom of the pretreatment tank to aerate the incoming water to fully oxidize the sulfide in the oily sewage; the pretreated The purpose is to oxidize the reducing sulfide in the oily sewage, which can reduce the inhibition of sulfide and other reducing substances on the metabolic activity of microorganisms in the degreasing bacteria agent, and ensure that the degradation effect of microorganisms on crude oil and other organic substances will not be reduced; At the same time, part of the slick oil is removed by flotation in the pretreatment tank;

[0043] ...

Embodiment 3

[0056] The invention discloses a low-permeability oilfield oily sewage treatment process, which treats the sewage contained in a certain sewage treatment station in the oilfield, and the daily sewage treatment volume is 240m 3 / d; the working temperature of the system is 20-35°C; the pH is 6-9, and the processing mainly includes the following steps:

[0057] step 1)

[0058] Pretreatment: The oily sewage from the formation first enters the pretreatment tank, and an air aeration device is installed at the bottom of the pretreatment tank to aerate the incoming water to fully oxidize the sulfide in the oily sewage; the pretreated The purpose is to oxidize the reducing sulfide in the oily sewage, which can reduce the inhibition of sulfide and other reducing substances on the metabolic activity of microorganisms in the degreasing bacteria agent, and ensure that the degradation effect of microorganisms on crude oil and other organic substances will not be reduced; At the same time,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com