Multi-chamber fluidized bed reactor

A multi-chamber fluidized bed and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problem of large material level drop, reduced space utilization of fluidized bed reactors, and limited particle material delivery flux and other problems, to achieve the effect of suppressing cross-wind, improving charcoal burning efficiency, and avoiding material back-mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

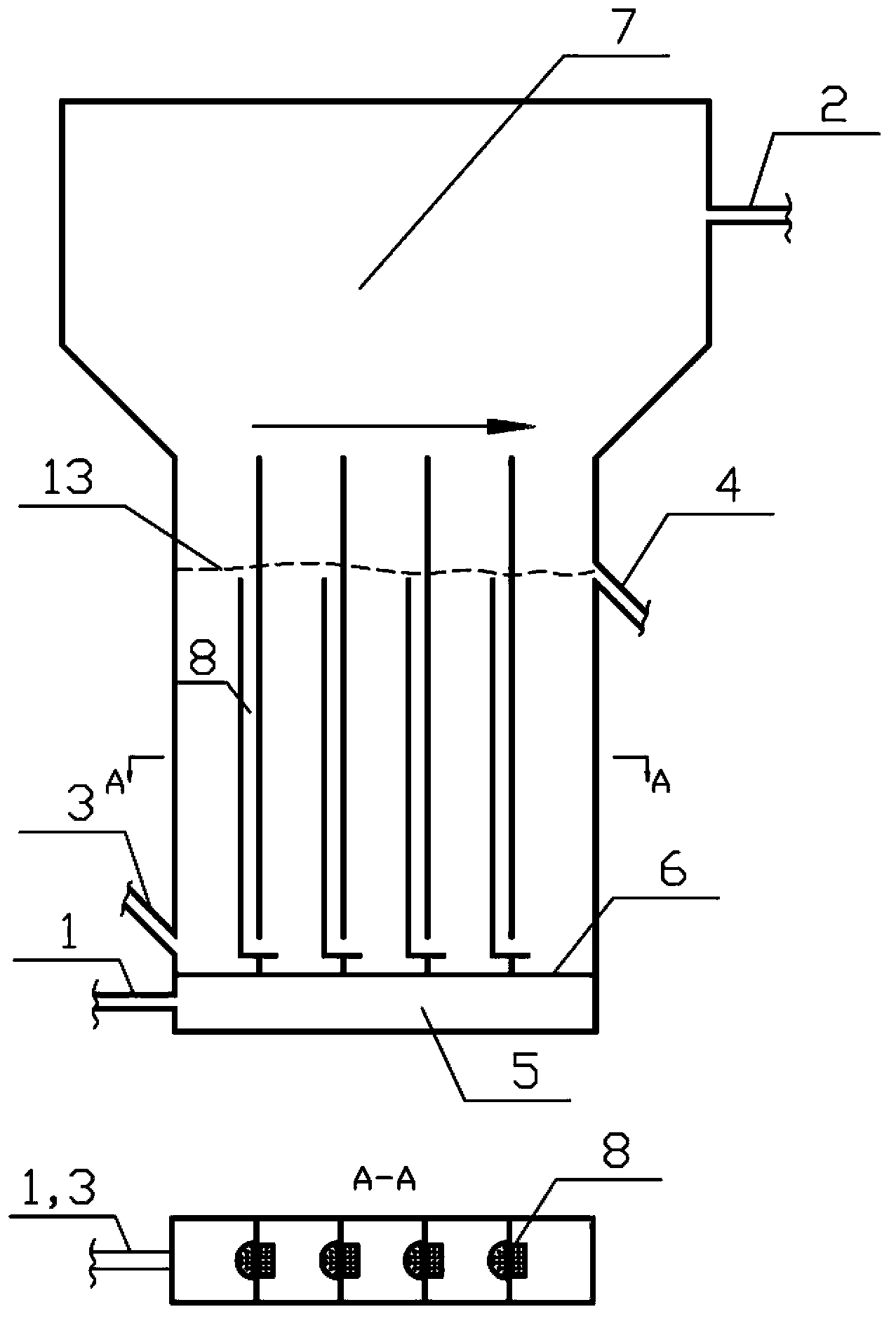

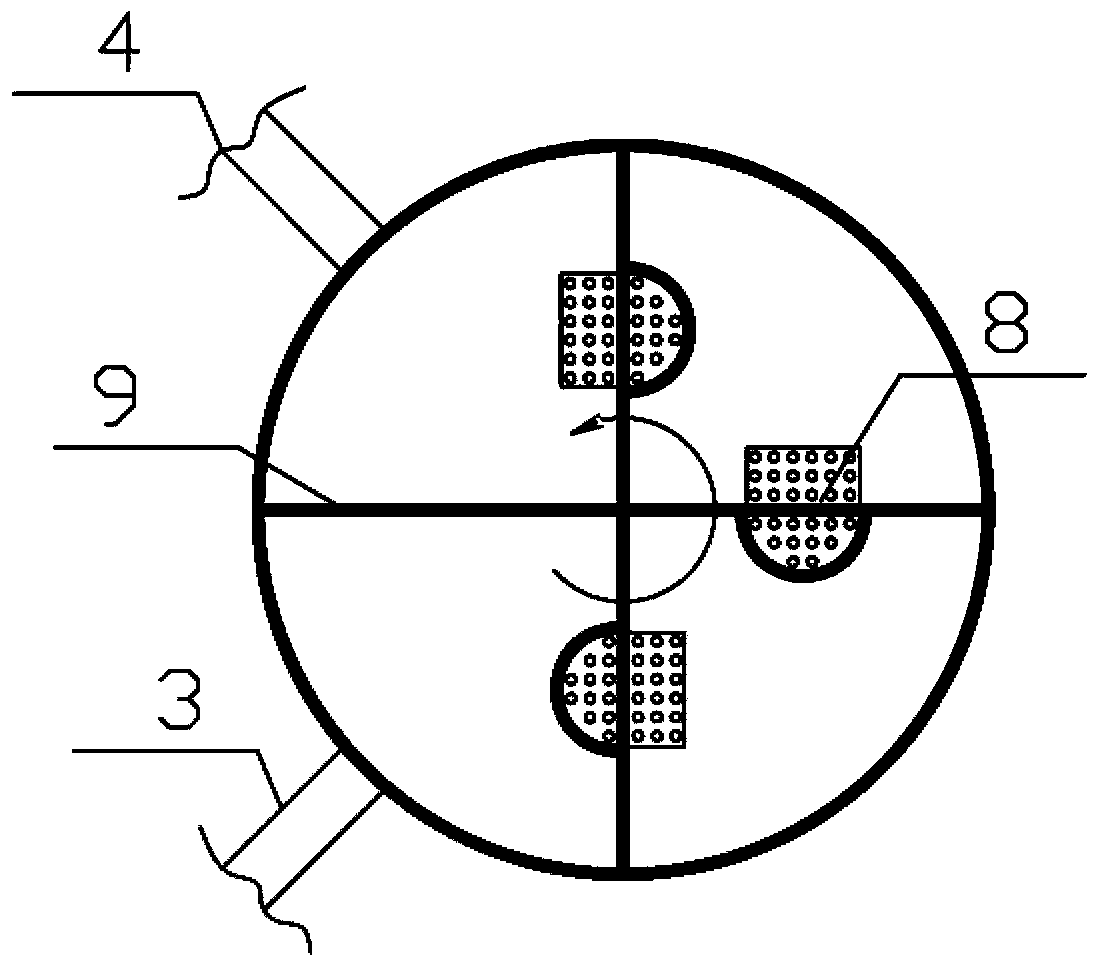

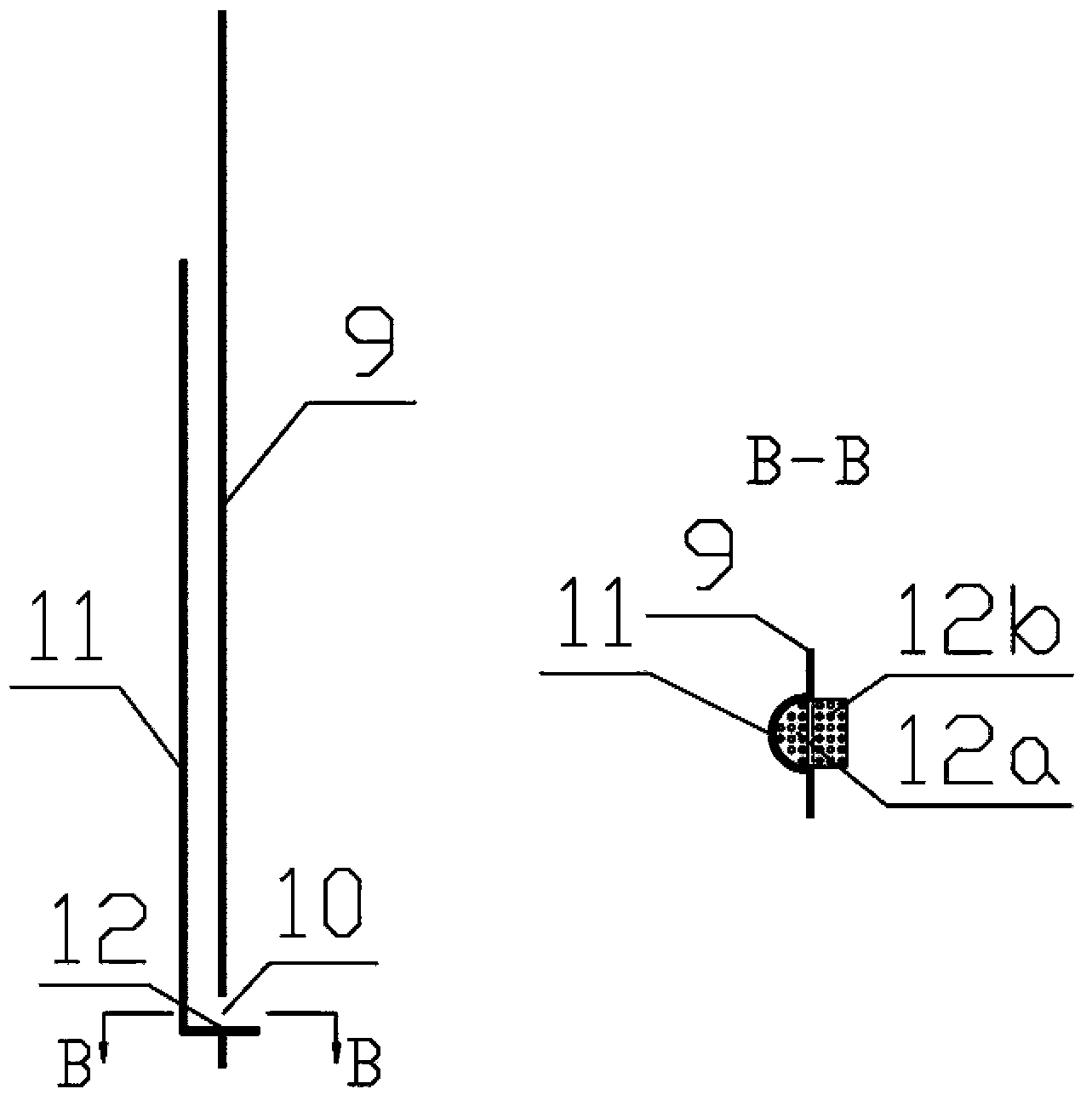

[0033] A rectangular multi-chamber fluidized bed reactor, consisting of an air inlet, an air outlet, a material inlet, a material outlet, an air chamber, an air distribution plate, a fluidization chamber and 4 built-in material flow controllers, 4 pieces The partitions are arranged in parallel, dividing the fluidized bed reactor into 5 secondary chambers from left to right, the air inlet is connected to the air chamber, the air outlet is connected to the upper part of the fluidization chamber, and the feed port is connected to the first secondary flow In the fluidization chamber, the discharge port is connected to the fifth-stage fluidization chamber, and the materials flow sequentially from left to right. The material flow controller consists of partitions, orifices, material downflow tubes and bottom baffles. The orifice on the partition is square, and the area of the orifice is 1 / 20 of the area of the partition. The downward flow pipe of the material is a semicircular ...

Embodiment 2

[0035] A rectangular multi-chamber fluidized bed reactor consisting of an air inlet, an air outlet, a material inlet, a material outlet, an air chamber, an air distribution plate, a fluidization chamber and three built-in partitions, the three partitions Arranged in parallel, the fluidized bed reactor is divided into 4 secondary chambers from left to right, the air inlet is connected to the air chamber, the air outlet is connected to the upper part of the fluidization chamber, and the feed port is connected to the first secondary fluidization chamber , the discharge port is connected to the fourth secondary fluidization chamber, and the materials flow sequentially from left to right. The material flow controller consists of partitions, orifices, material downflow tubes and bottom baffles. The orifice on the partition is square, and the area of the orifice is 1 / 10 of the area of the partition. The downward flow pipe of the material is a square pipe, the cross-sectional are...

Embodiment 3

[0037] A rectangular multi-chamber fluidized bed reactor consisting of an air inlet, an air outlet, a material inlet, a material outlet, an air chamber, an air distribution plate, a fluidization chamber and two built-in partitions, the two partitions Arranged in parallel, the fluidized bed reactor is divided into three secondary chambers from left to right, the air inlet is connected to the air chamber, the air outlet is connected to the upper part of the fluidization chamber, and the feed port is connected to the first secondary fluidization chamber , the discharge port is connected to the third secondary fluidization chamber, and the materials flow sequentially from left to right. The material flow controller consists of partitions, orifices, material downflow tubes and bottom baffles. The orifice on the partition is semicircular, and the area of the orifice is 1 / 10 of the area of the partition. The downward flow pipe of the material is a semicircular pipe, and the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com