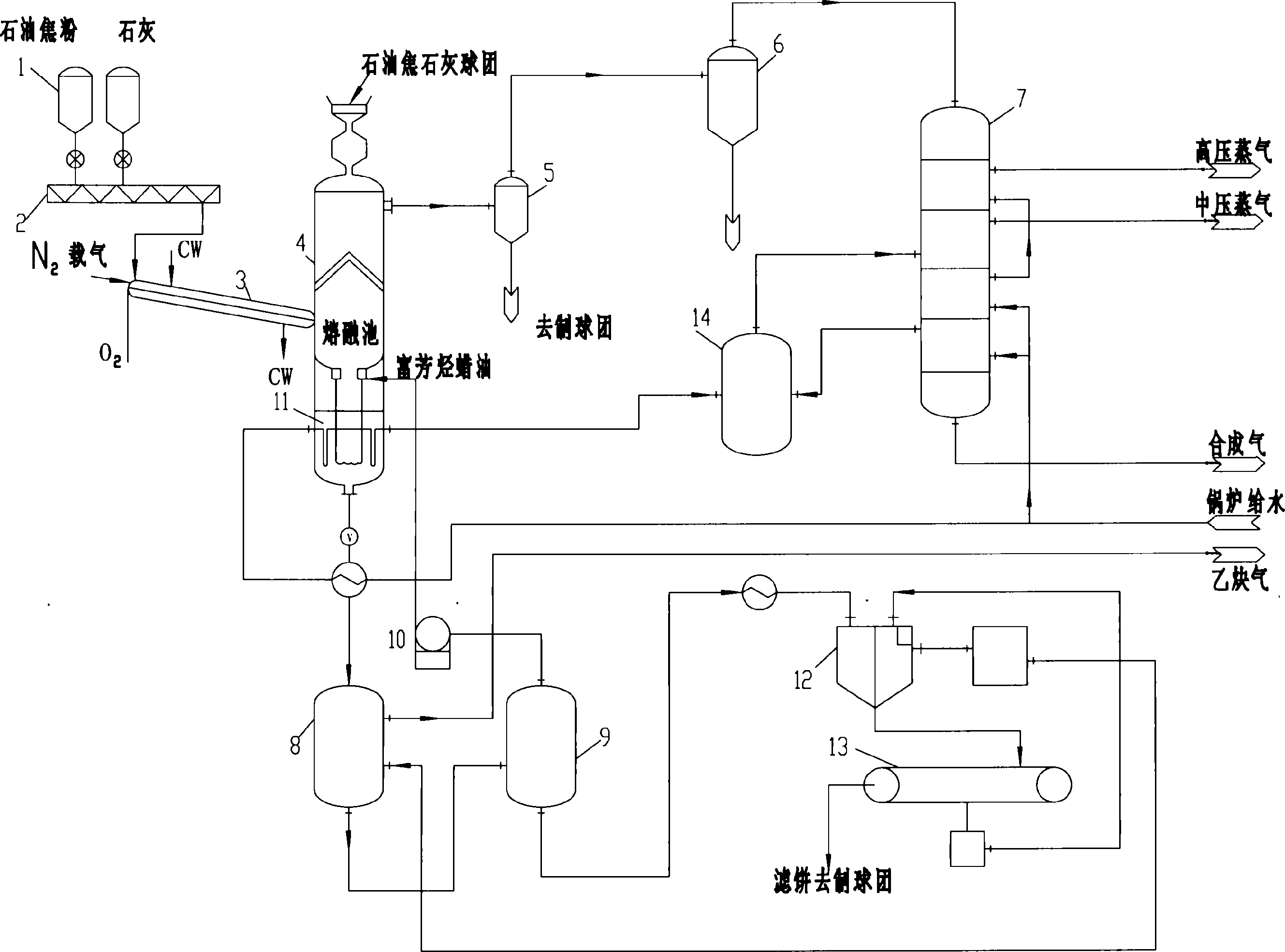

Process of co-producing acetylene and synthetic gas with petroleum coke and low ash coal

A synthesis gas and petroleum coke technology, applied in the field of chemical engineering, can solve the problems of high patent royalty, difficult petroleum coke ash, complex gasifier structure, etc., and achieve the effect of saving power and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0046] Using 37.5 tons of (water-free and ash-free) petroleum coke per hour as raw material, this gasification method can produce 7.2 tons of acetylene per hour, (CO+H 2 ) Gas 91360NM 3 / hour, for processing into methanol, 40.90 tons / hour of methanol can be obtained.

[0047] 37.5 tons (without water and ash) of petroleum coke are divided into two parts and added to the gasifier, of which 23.37 tons of petroleum coke is mixed with 5.17 tons of lime, mixed and dried with 33.870NM 3 Oxygen is sent into the reaction chamber of the gasification furnace through the spray gun, and the partial oxidation reaction is carried out at a temperature of 2200 ° C to 2500 ° C and a pressure of 10 to 30 atmospheres, and the generated molten calcium carbide drops to the rear reaction area of the gasification furnace. Another part of 14.13 tons of petroleum coke is mixed with 14.30 tons of lime to make pellets into the furnace from the top of the gasification furnace. The pellets react with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com