Auxiliary gasification technique using synthesis gas to burnback and equipment thereof

A technology for syngas backburning and gasification equipment, applied in the field of gasification furnaces, can solve the problems of poor adaptability to fluctuations in fuel characteristics, achieve the effects of reducing output and composition fluctuations, improving quality, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

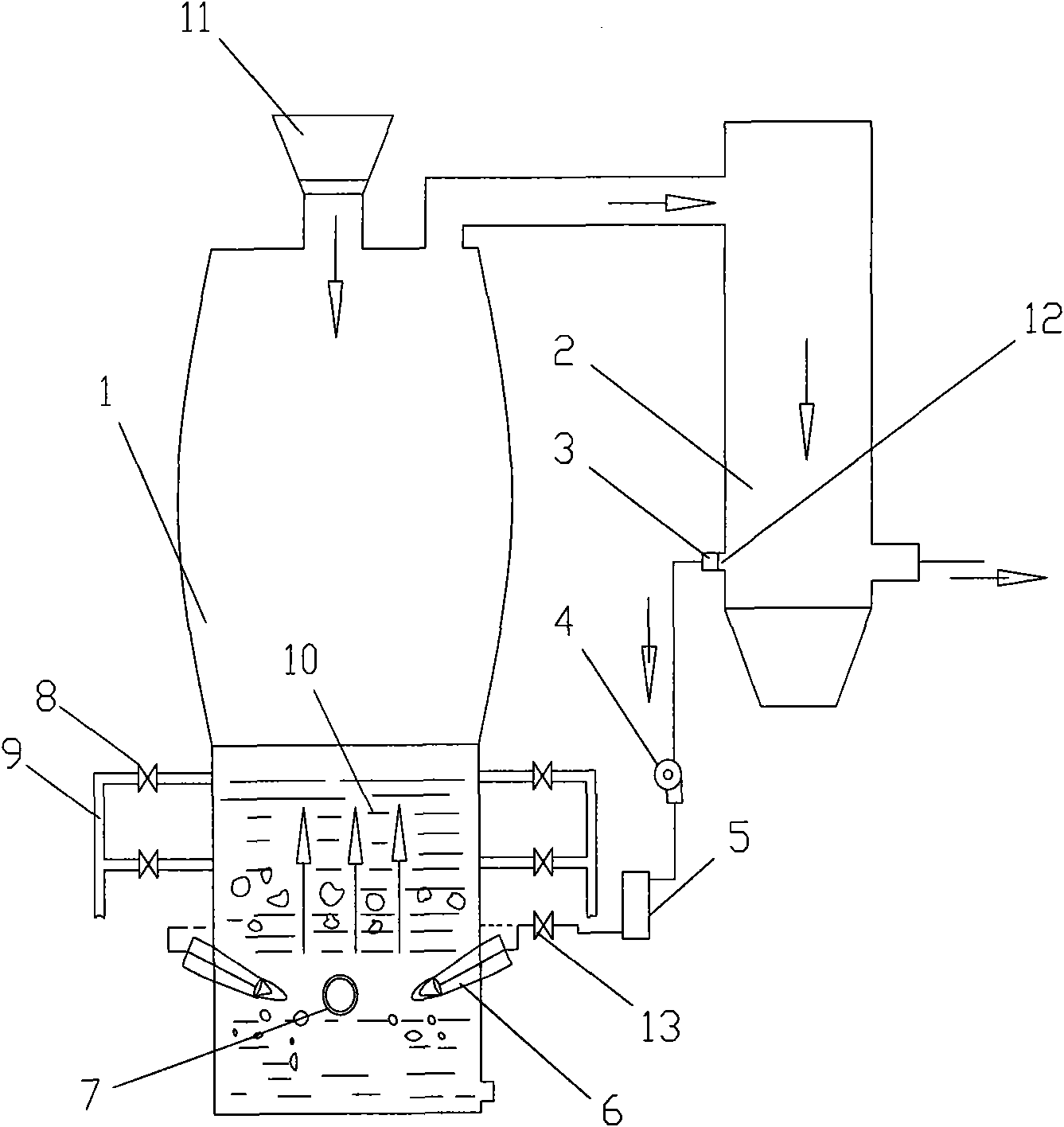

[0022] Below in conjunction with accompanying drawing and specific embodiment, equipment and process of the present invention are described in further detail:

[0023] The auxiliary gasification equipment using syngas backburning shown in the figure has a gasification furnace 1 and supporting follow-up processing equipment 2 . The top of the gasifier 1 is provided with a feeder 11 , the lower part of the gasifier 1 is laid with a raw material bed 10 , the combustion chamber is located below the raw material bed 10 , and the bottom of the gasifier 1 is provided with a slag outlet. The top synthesis gas outlet of the gasifier 1 is connected to the synthesis gas inlet of the subsequent processing equipment 2 . The subsequent processing equipment 2 is provided with a syngas extraction port 12, and the ash filter device 3 is installed at the syngas extraction port 12. The ash filter device 3 is connected to the input end of the circulation fan 4 through the synthesis gas delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com