Municipal solid waste pyrolysis gasification furnace and pyrolysis gasification method

A technology of pyrolysis and gasification of municipal solid waste, applied in the field of pyrolysis gasification furnace and pyrolysis gasification of municipal solid waste, can solve the problems of flue gas pollution, improper control of incineration conditions, etc., and achieve faster processing speed and material disturbance Strong, the effect of reducing the generation of dioxin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

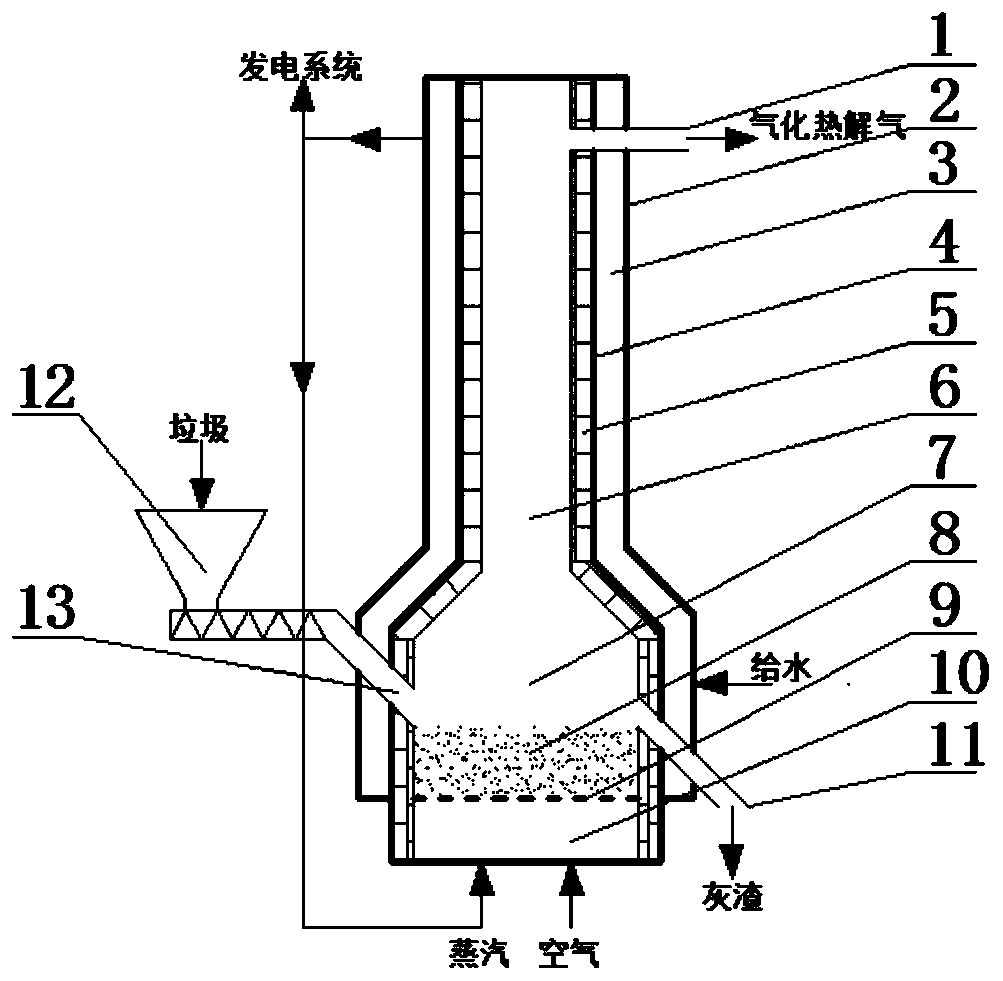

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, in the municipal solid waste pyrolysis gasification furnace, the crushed municipal solid waste enters the fluidized bed section 7 of the pyrolysis gasification furnace from the garbage inlet 13 after passing through the screw feeder 12, and in the fluidized bed section 7 is in contact with the high-temperature bed material 8, and pyrolysis reaction occurs after the garbage is heated to generate pyrolysis gas and semi-coke. Steam and air enter the air chamber 10 at the bottom of the pyrolysis gasifier, pass through the air distribution plate 9 and then enter the fluidized bed section 7, react with the semi-coke in the bed, release heat, heat the bed material 8, semi-coke and steam After reacting with air, gasification gases such as carbon monoxide and hydrogen and ash are generated, and the ash is discharged from the ash outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com