Quick heating and gasifying test device and application thereof

A test device, fast technology, applied in the investigation stage/state change, etc., can solve the problems of low operating temperature, long test time, expensive price, etc., and achieve the effect of high gasification temperature, high cost performance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

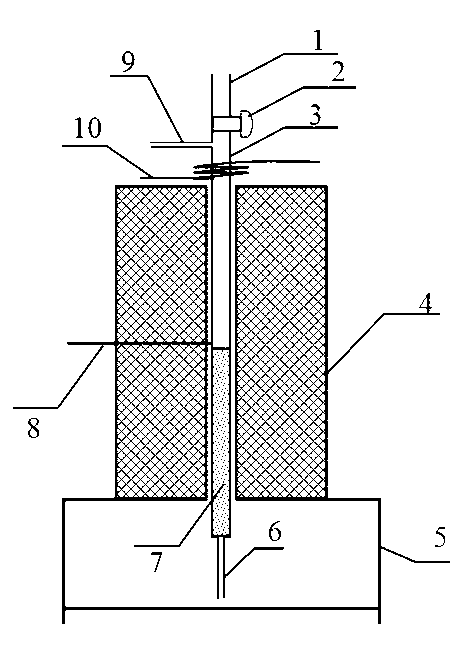

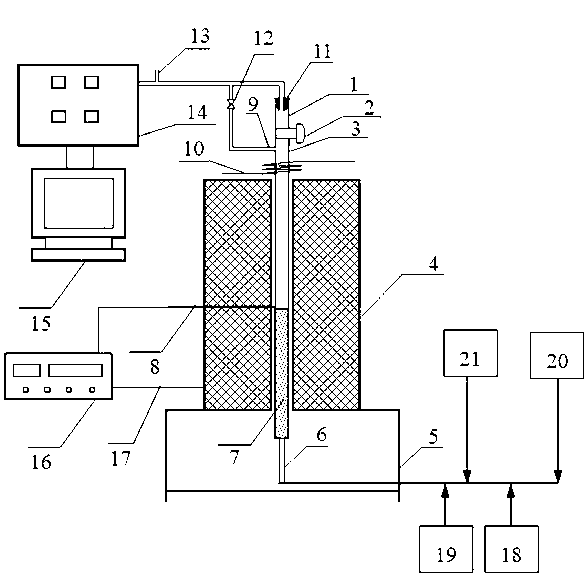

[0030] The middle part of the reaction tube 3 of the rapid temperature rise gasification test device is located in the tubular electric heating furnace 4, and the bottom end of the reaction tube 3 is an air inlet 6, and the lower part of the reaction tube 3 is equipped with a quartz sand packing layer 7. There is a cooling water device 10 outside the reaction tube 3 above the furnace 4, and the reaction tube 3 above the cooling water device 10 is equipped with a Q611F feeding valve 2 produced by Shanghai Qigao Valve Manufacturing Co., Ltd., and the gas outlet is above the feeding valve 2 1. The reaction tube 3 between the cooling water device 10 and the feeding valve 2 has a side gas outlet 9, and a thermocouple 8 is installed in the middle of the reaction tube 3 above the quartz sand packing layer 7, and a tubular electric heating furnace 4 Located on bracket 5.

[0031] (1), connect the temperature controller 16 with the thermocouple 8 and the tubular heating furnace 4, and ...

Embodiment 2

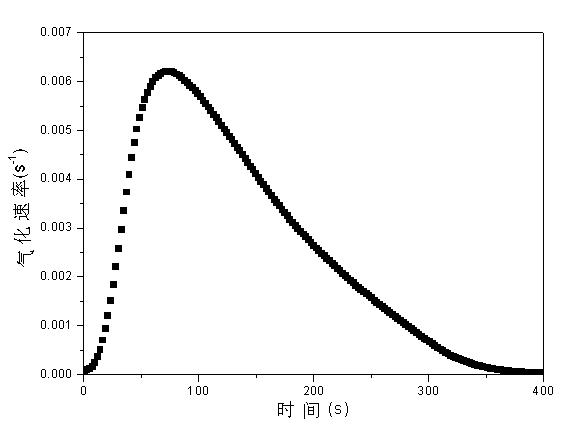

[0039] The packing layer 7 is aluminum silicate fiber, and the feeding valve 2 is the Q11F type produced by Changzhou SMS Automatic Control Valve Co., Ltd. The sample is petroleum coke, the dosage is 500 mg, the reaction atmosphere is a mixture of water vapor and argon, and the gasification temperature is 1600° C. Others are the same as in Example 1. The gasification rate of petroleum coke in a mixed atmosphere of water vapor and argon is shown in Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com