Fluidized bed heavy oil cracking and gasification graded conversion device and fluidized bed heavy oil cracking and gasification graded conversion method

A heavy oil cracking and conversion device technology, which is applied in the direction of multi-stage series refining and cracking process treatment, can solve the problems of difficult engineering design, waste of heavy oil resources, complex process, etc., and achieve high effective gas composition of syngas, The effect of high conversion rate of heavy oil and high liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

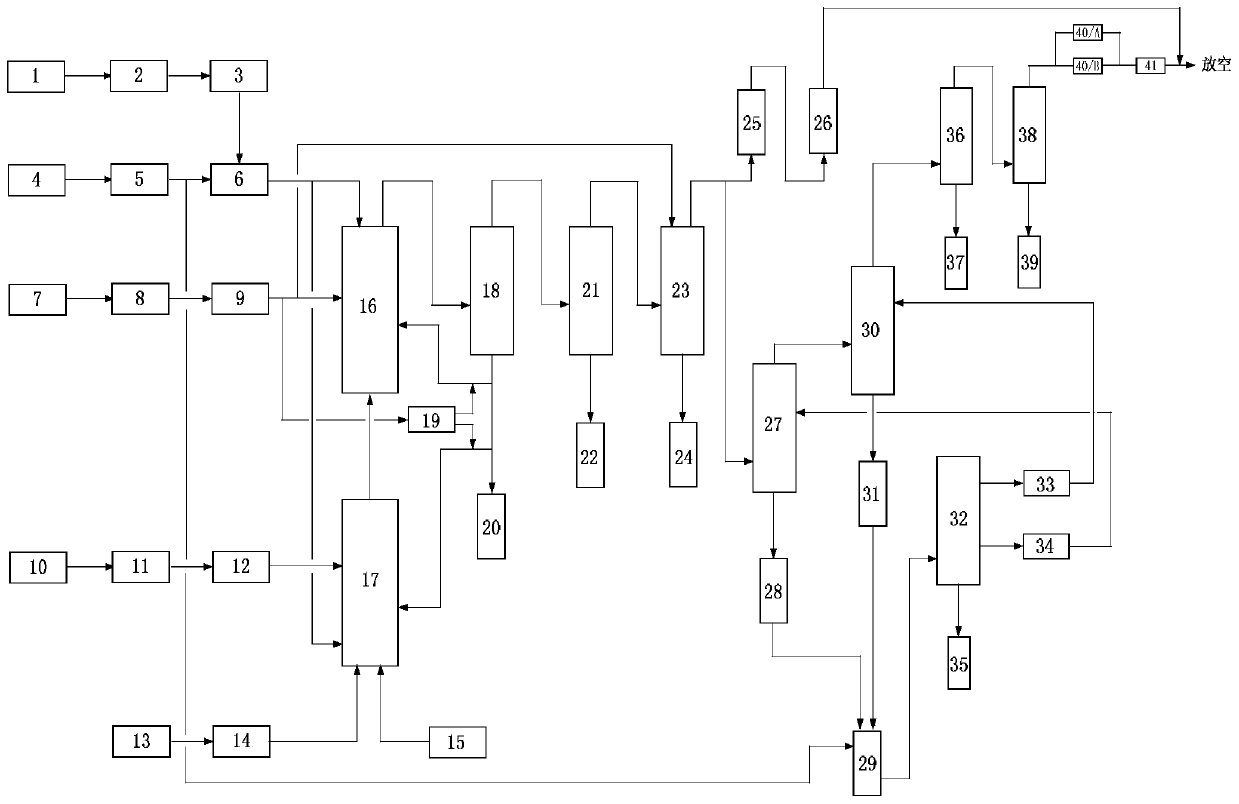

[0045] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail.

[0046] see figure 1 , The device of the present invention includes a feed unit, a carrier gas unit, a cracking-gasification unit, a cooling recovery unit, a gas-liquid separation unit and a light oil recovery unit:

[0047] The feed unit includes a steam system, a heavy oil system and a solid particle system;

[0048] The steam system includes a pressurized metering pump 1, an electric steam generator 2 and a steam superheater 3 connected in sequence with the steam source;

[0049] The heavy oil system includes a heavy oil pressurized feed pump 4, a heavy oil preheater 5, and a heavy oil sprayer 6 connected in sequence to the heavy oil source, and the saturated steam produced by the steam superheater 3 of the steam system is combined with the gas from the heavy oil sprayer 6. connected to the road entrance;

[0050] The solid particle system includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com