Method and device for heating down-draft biomass gasifier by exhaust gas of engine

A gasifier and biomass technology, which is applied to exhaust devices, engine components, combustion engines, etc., can solve the problems of insufficient temperature and difficult to achieve tar cracking, and achieve the effect of solving purification problems, easy implementation and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

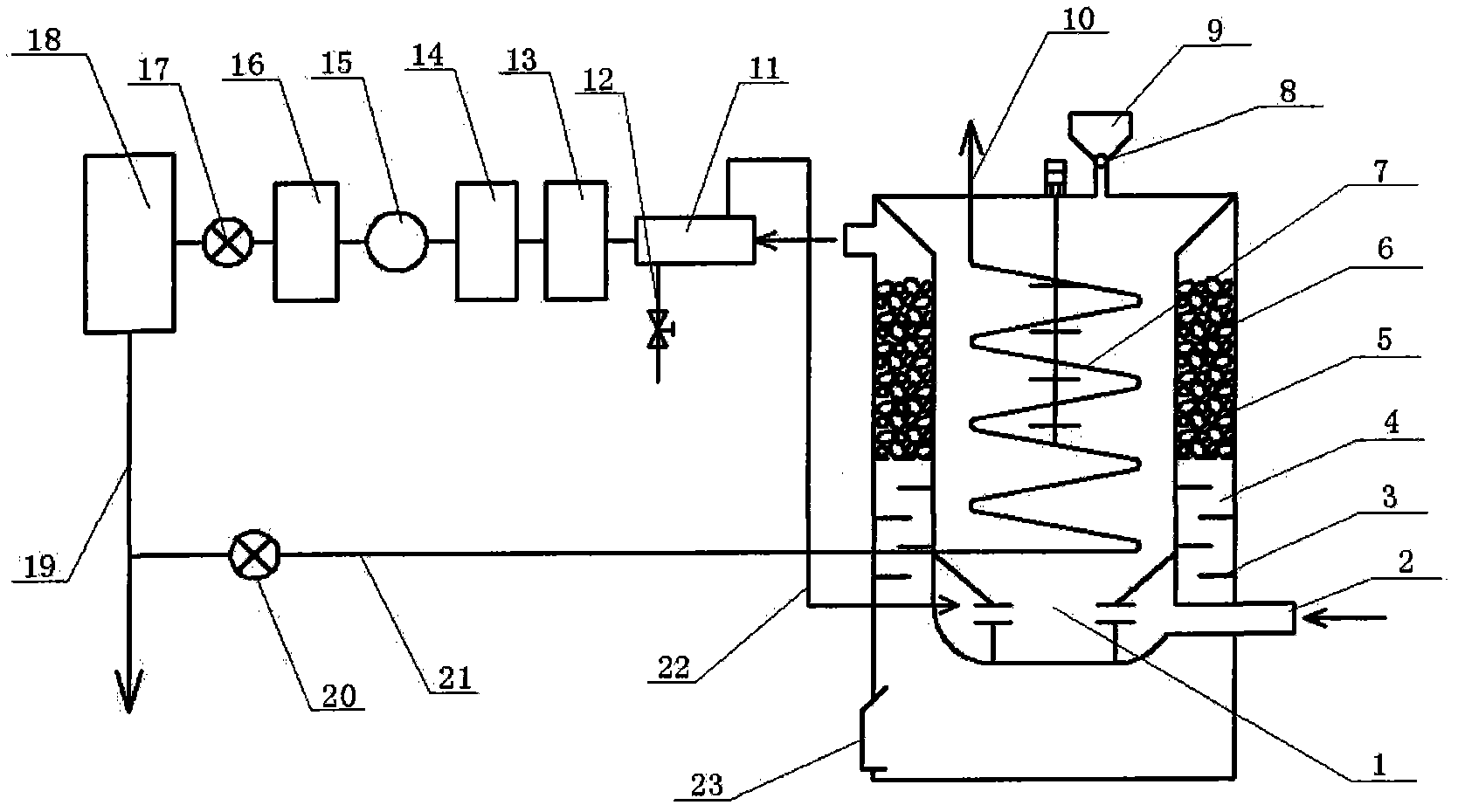

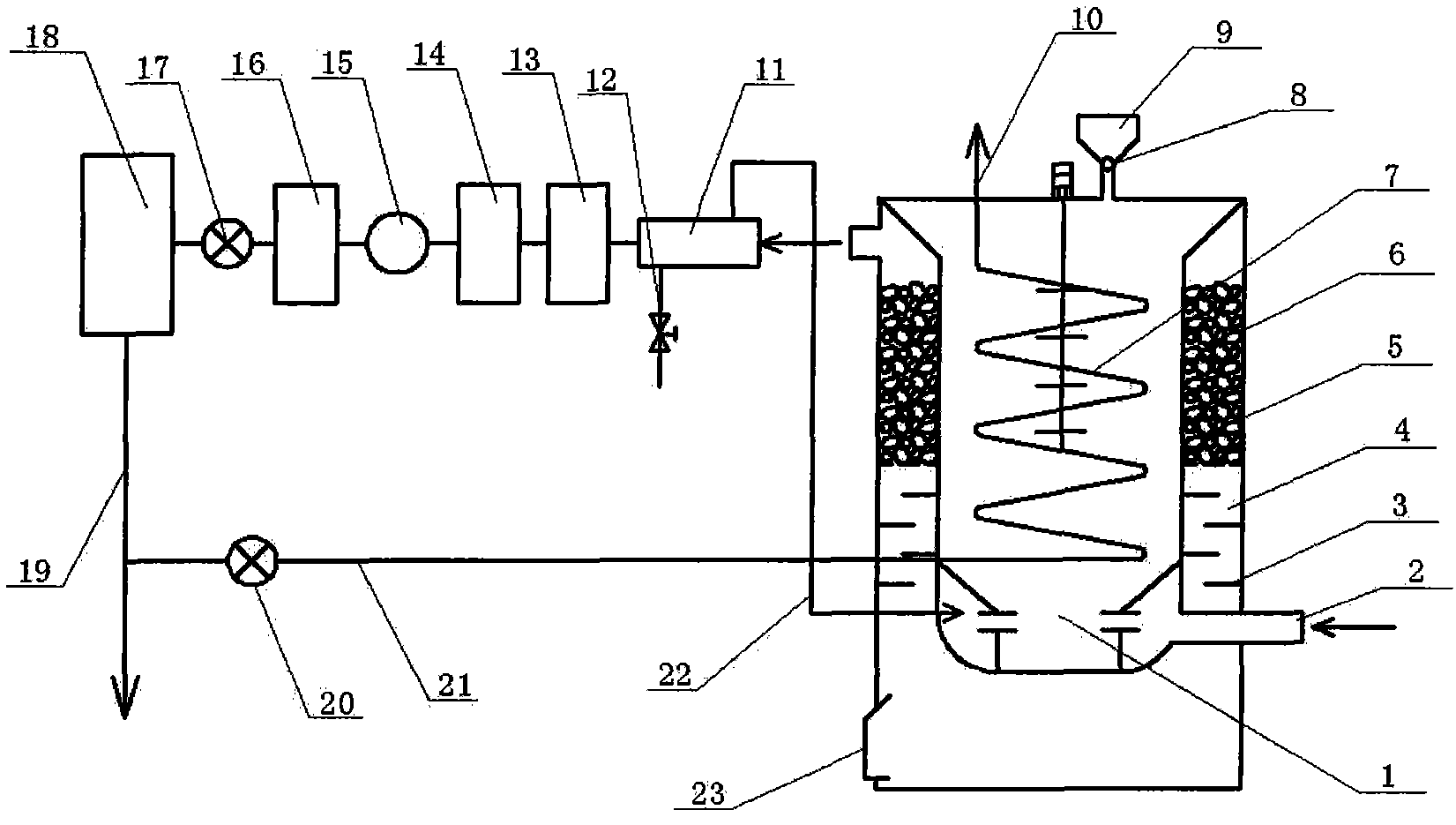

[0023] As shown in the drawings, the biomass gasification equipment in the embodiment of the present invention adopts a fixed-bed downdraft biomass gasification furnace 1, and the biomass raw material is fed from the hopper 9, and the material falls into the furnace through the feeding mechanism 8, and passes through layers The slide moves gradually towards the bottom of the furnace. Air, which is one of the gasification agents, enters from the air inlet pipe 2 . The biomass is first dried in the furnace, and after reaching a certain temperature, it undergoes pyrolysis and precipitates volatile matter, and then undergoes oxidation and reduction reactions with the gasification agent; the ash produced by the biomass after fully reacting falls into the ash chamber at the lower part of the gasification furnace , the ash chamber is provided with ash outlet 23. The fuel gas generated by the reaction in the gasification furnace flows upwards from the lower part of the furnace body t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com