Fixed-bed grading and gasifying continuous gas producing furnace

A fixed-bed, gas-making furnace technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve problems such as difficult control of furnace temperature, blowing air emission, energy waste, etc., and improve energy utilization rate , increase gasification intensity, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

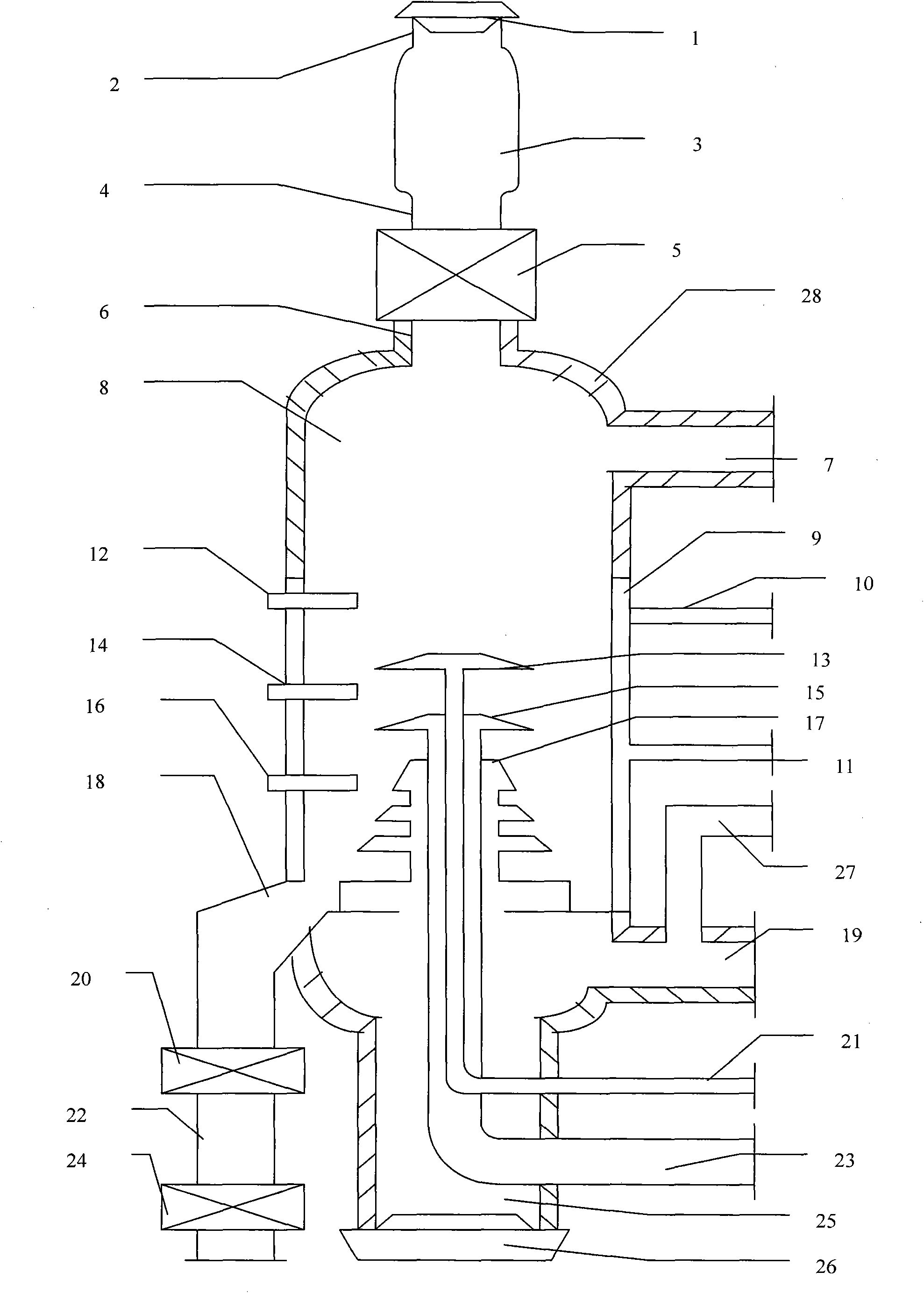

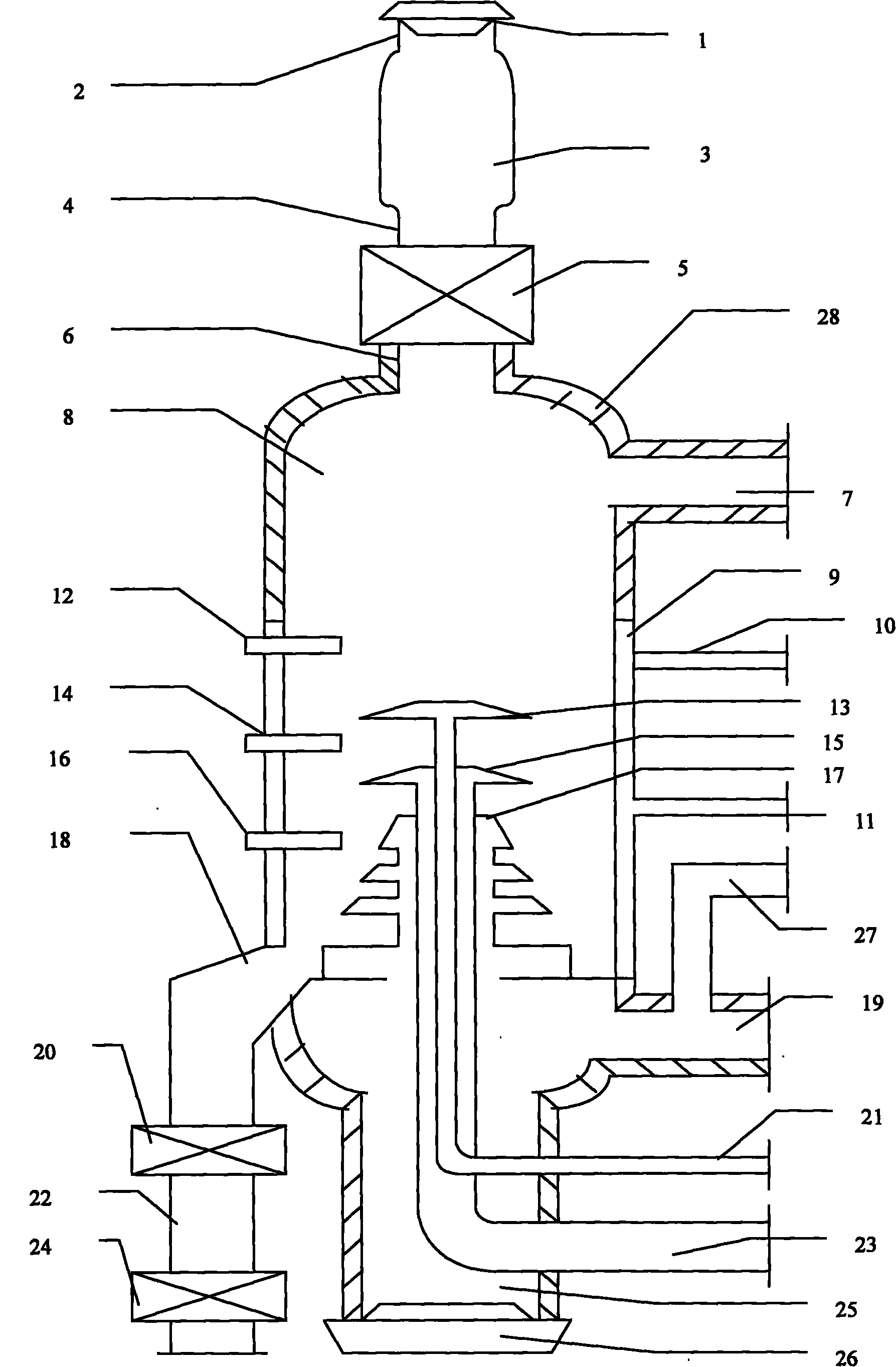

[0025] The fixed-bed staged gasification continuous gasification furnace uses coal, coke or briquette in the heat storage process to utilize the action of the upward furnace temperature and gasification agent, and uses a three-stage gas distribution tower for staged gasification, through three temperature monitors (12 , 14, 16) Monitor the temperature of each reaction zone, adjust the amount of gasification agent according to the monitored temperature, control the temperature and gasification conditions of each reaction zone in the furnace, maintain the heat balance in the furnace, ensure the quality of gasification, and make it form a continuous Stable gasification effect, semi-water gas required for the production of synthetic ammonia and urea, or water gas and gas with high carbon monoxide content required for the production of synthetic methanol.

[0026] The raw material enters the silo (3) through the silo sealing cover (1) and the feeding pipe (2) for storage. According ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com