Stamping device for shells of mini-tillers

The technology of a stamping device and a micro-tiller is applied in the field of sheet metal stamping, which can solve the problems of time-consuming and laborious, affecting the aesthetics of the shell, and achieve the effect of easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below by means of specific embodiments:

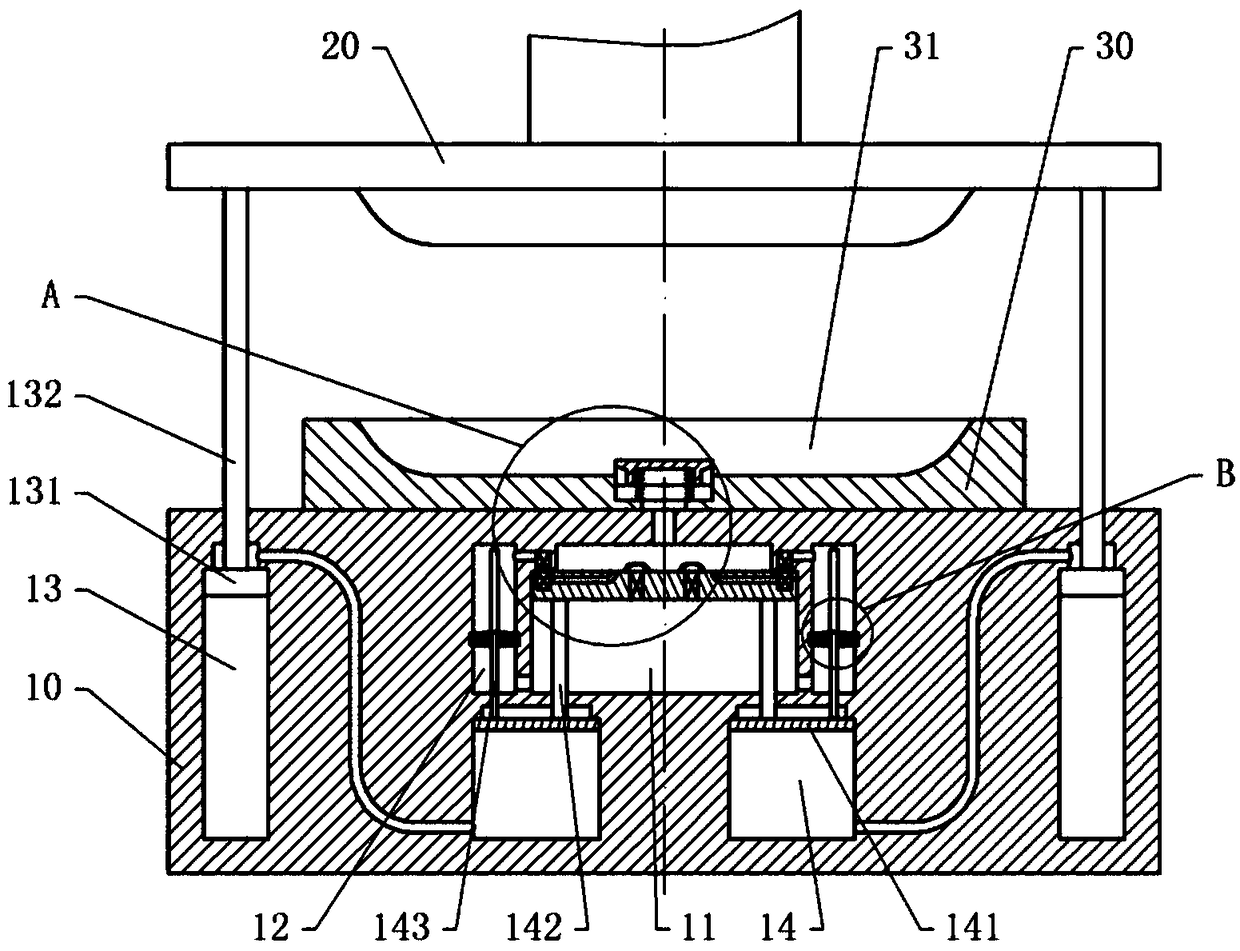

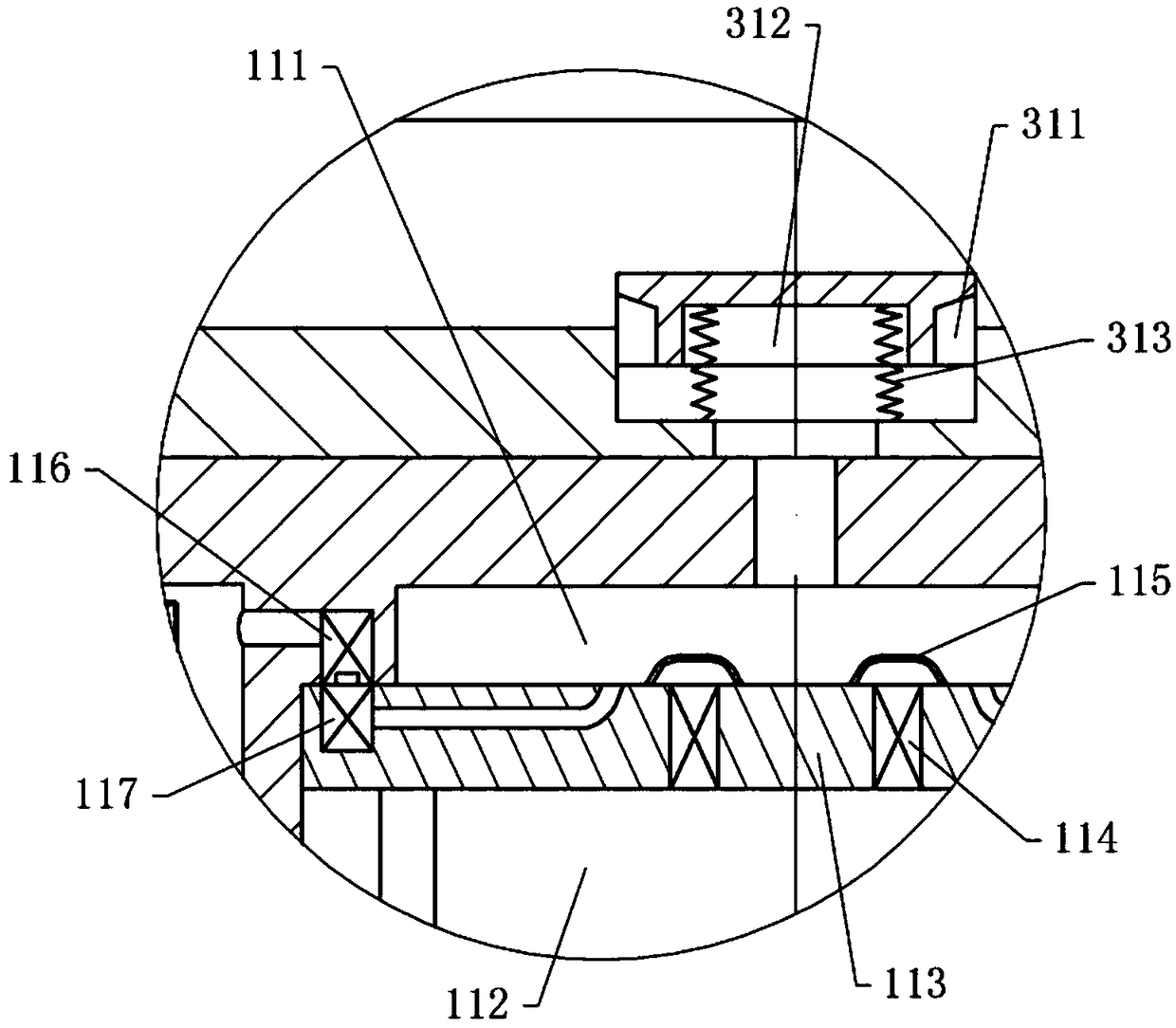

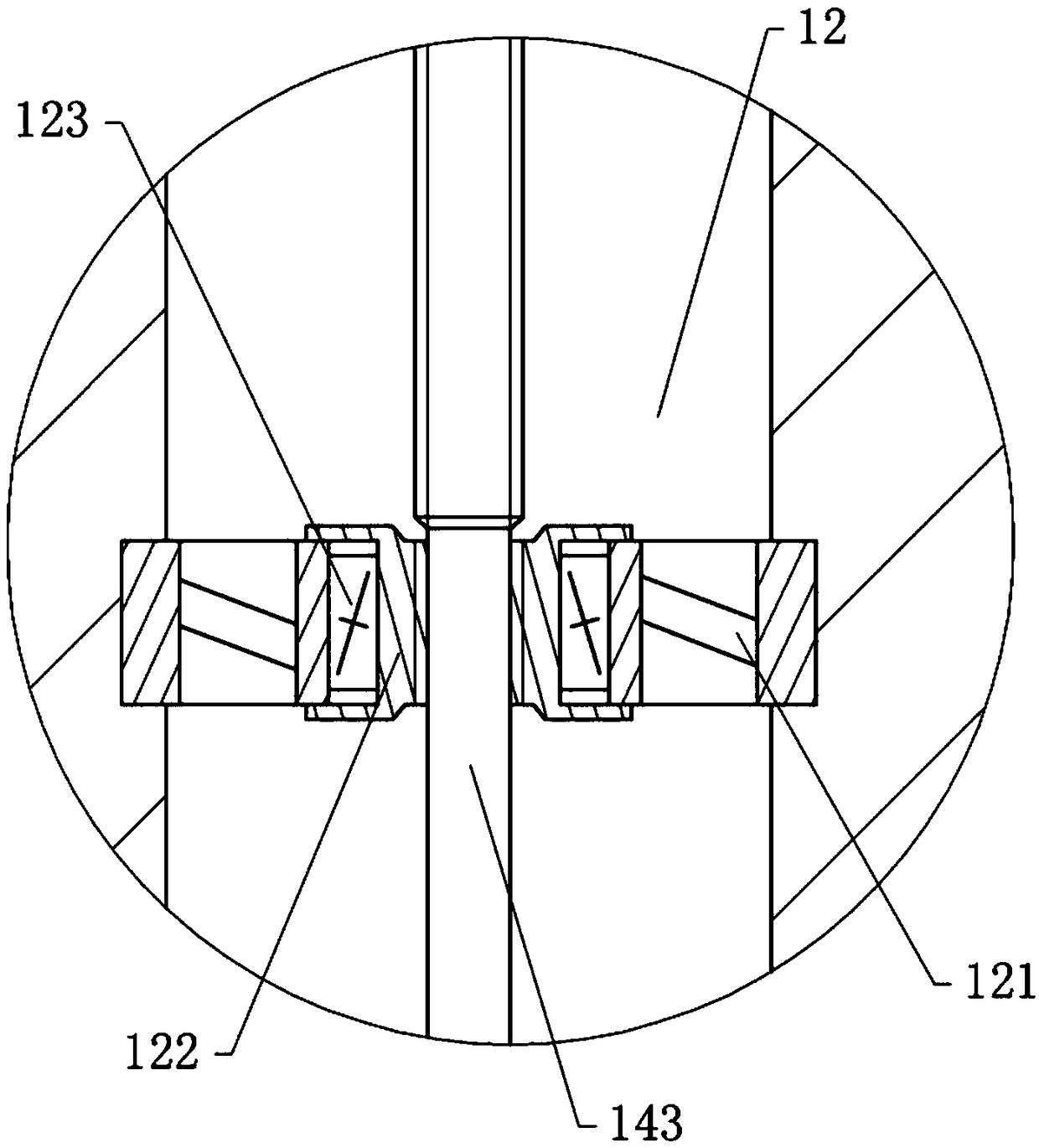

[0025] The reference signs in the accompanying drawings include: seat body 10, liquid chamber 11, first chamber 111, second chamber 112, first piston plate 113, one-way valve 114, filter screen 115, first quick connector 116, second Two quick connectors 117, diversion channel 12, pump wheel 121, drive ring 122, one-way bearing 123, first oil chamber 13, piston 131, connecting rod 132, second oil chamber 14, second piston plate 141, push rod 142, drive rod 143, punch 20, die 30, launder 311, blocking block 312, stage clip 313.

[0026] The embodiment is basically as figure 1 , figure 2 and image 3 Shown:

[0027] The stamping device of the tiller housing in this embodiment includes a base body 10, a die 30 fixed on the base body 10, a punch 20 which is arranged above the die 30 and can cooperate with the die 30, and drives the punch 20 up and down. A moving stamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com