Coupling structure for a shell

a technology of coupling structure and shell, applied in the direction of sheet joining, fastening means, hook fasteners, etc., can solve the problem that the circuit design engineer is unable to achieve the goal of reducing a single centimeter in size, and achieve the effect of preventing untimely breakage enhancing the resiliency of the first and second hooks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

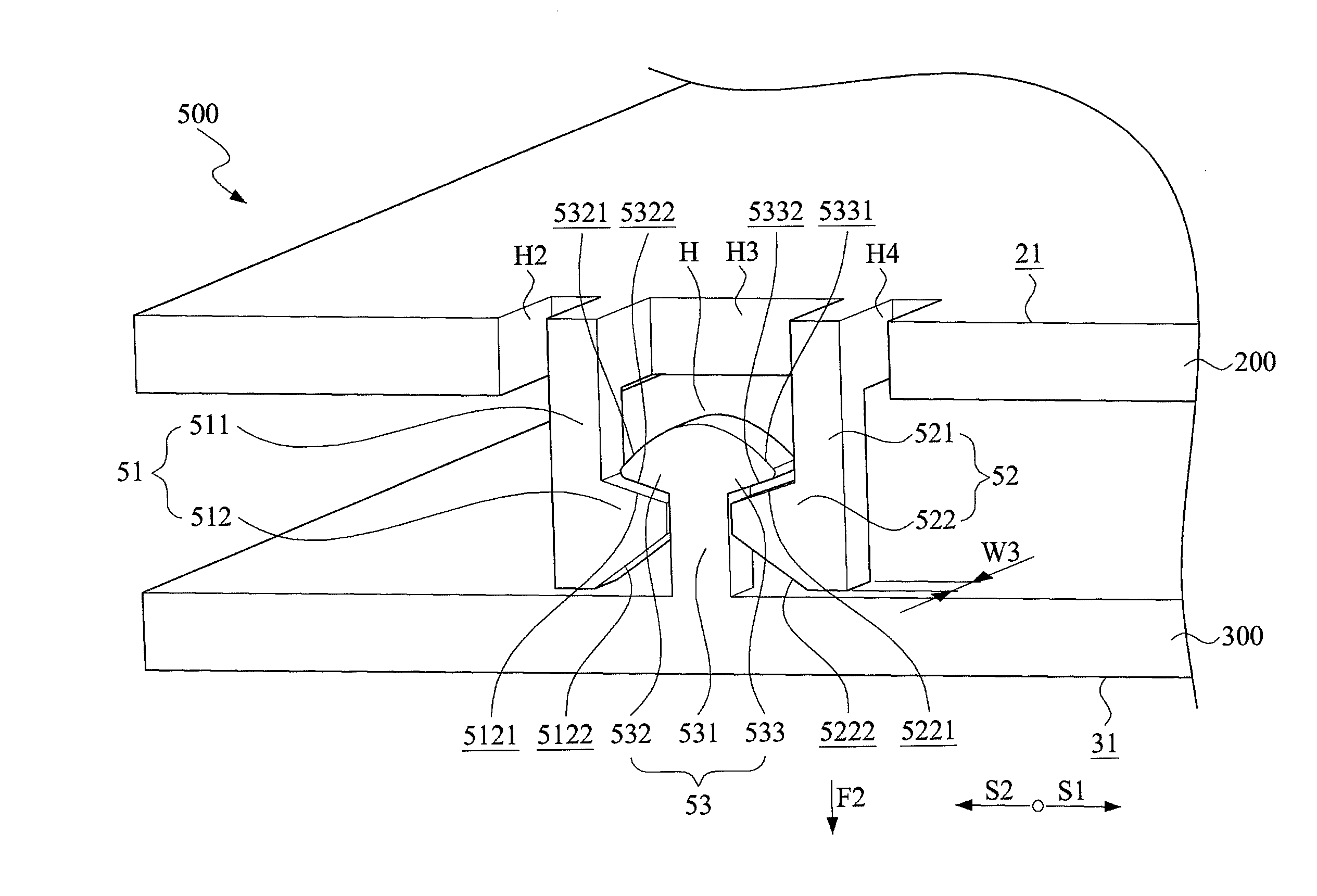

[0028]Referring to FIGS. 3 and 4, wherein FIG. 3 shows a preferred embodiment of a coupling structure of the present invention prior to coupling first and second shell halves into a shell while FIG. 4 illustrates the preferred embodiment of the coupling structure of the present invention coupling the first and second shell halves into a shell. As shown, the coupling structure 500 of the present invention is disposed between the first and second shell halves 200, 300 juxtaposed to each other for coupling the same into the shell, and includes a first hook 51, a second hook 52 and a two-way securing hook 53. The first shell half 200 has a first side 21. The first hook 51 includes an elongated first resilient section 511 extending from the first side 21 towards the second shell half 300 and a first clamping section 512 extending laterally from the first resilient section 511 along a first direction S1.

[0029]The second hook 52 includes an elongated second resilient section 521 extending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com