Freight pallet

A freight pallet and suction cup technology, applied in the field of freight pallets, can solve the problems of unsolved pallet stability, slippage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

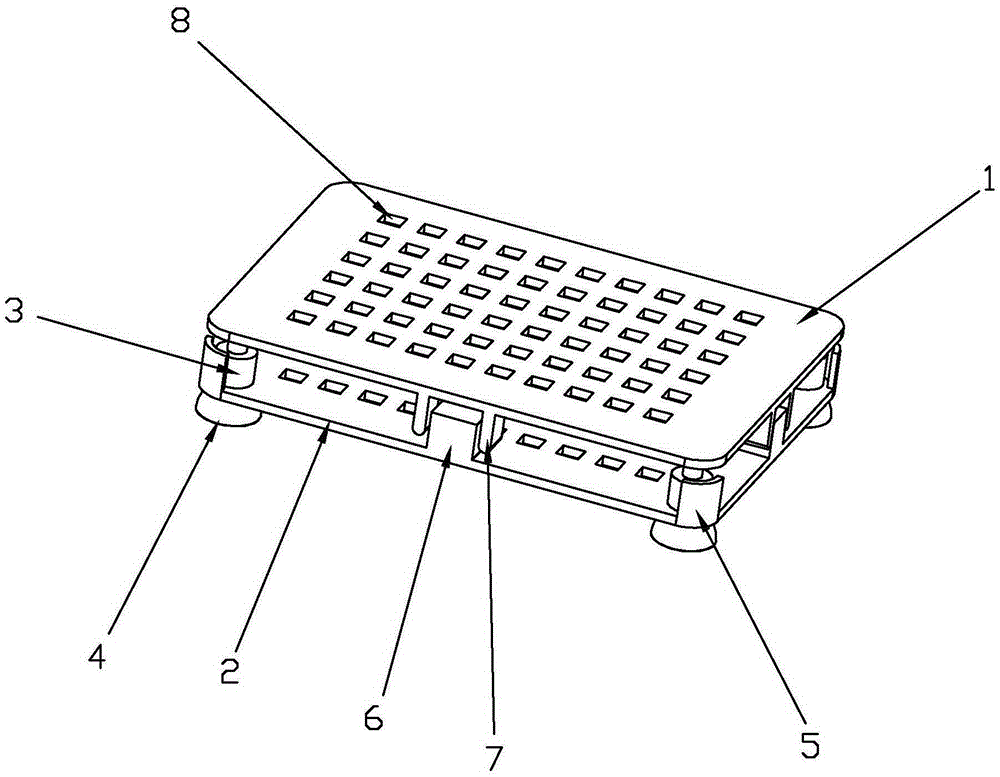

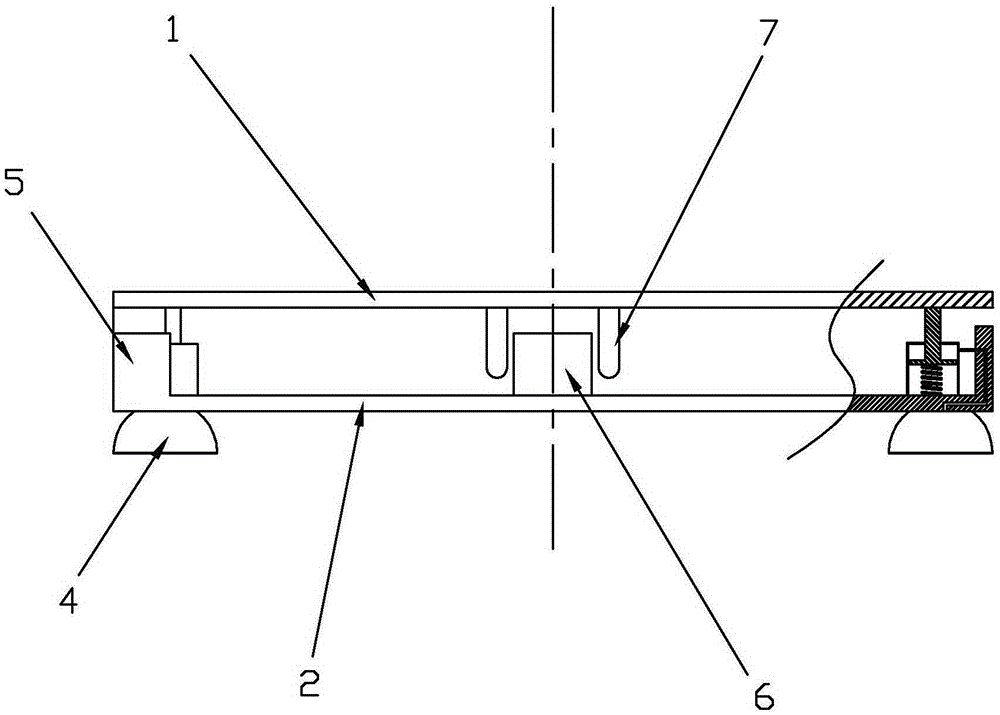

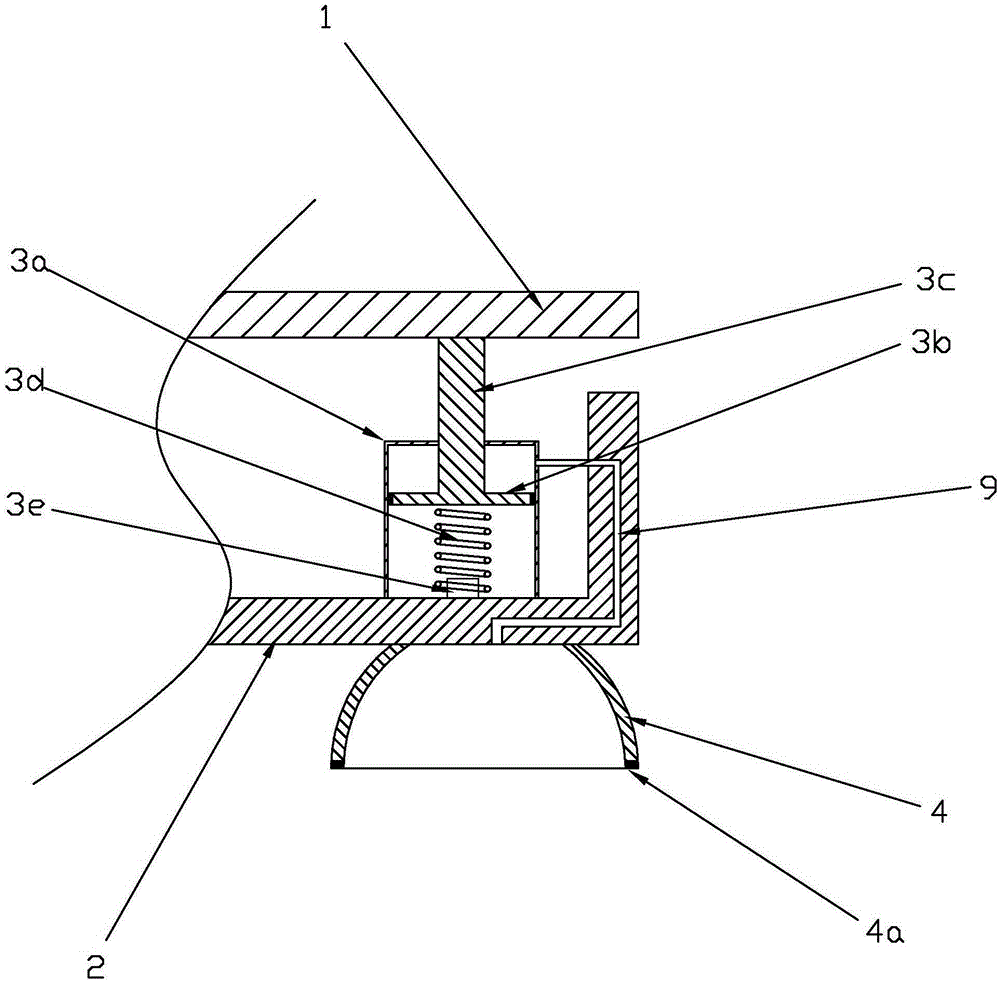

[0023] A shipping pallet, comprising a square material placement layer 1 and a directional ground contact layer 2, buffer devices 3 are provided at the four corners between the material placement layer 1 and the ground contact layer 2, and the buffer device 3 includes The sealed cylinder 3a on the layer 2, the sealed cylinder 3a is slidably connected with the piston disc 3b, the piston disc 3b divides the cylinder 3a into the upper chamber M and the lower chamber N which are not connected to each other, and the piston disc 3b is fixed with a piston The rod 3c and the piston rod 3c protrude upwards from the upper chamber M and are fixed on the material placement layer 1. The bottom of the ground contact layer 2 is provided with a suction cup 4, and a ventilation line 9 is provided between the upper chamber M and the suction cup 4. Since a ventilation pipeline 9 is provided between the buffer device 3 and the suction cup 4 , the working state of the buffer device 3 can affect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com