Watt-hour meter handling manipulator suitable for multi-meter-position tooling board

A technology of electric energy meter and tooling board, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of unsuitable production needs of industrial automation, high labor intensity, low work efficiency, etc., so as to avoid deviation of test results and improve production. Efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to the accompanying drawings.

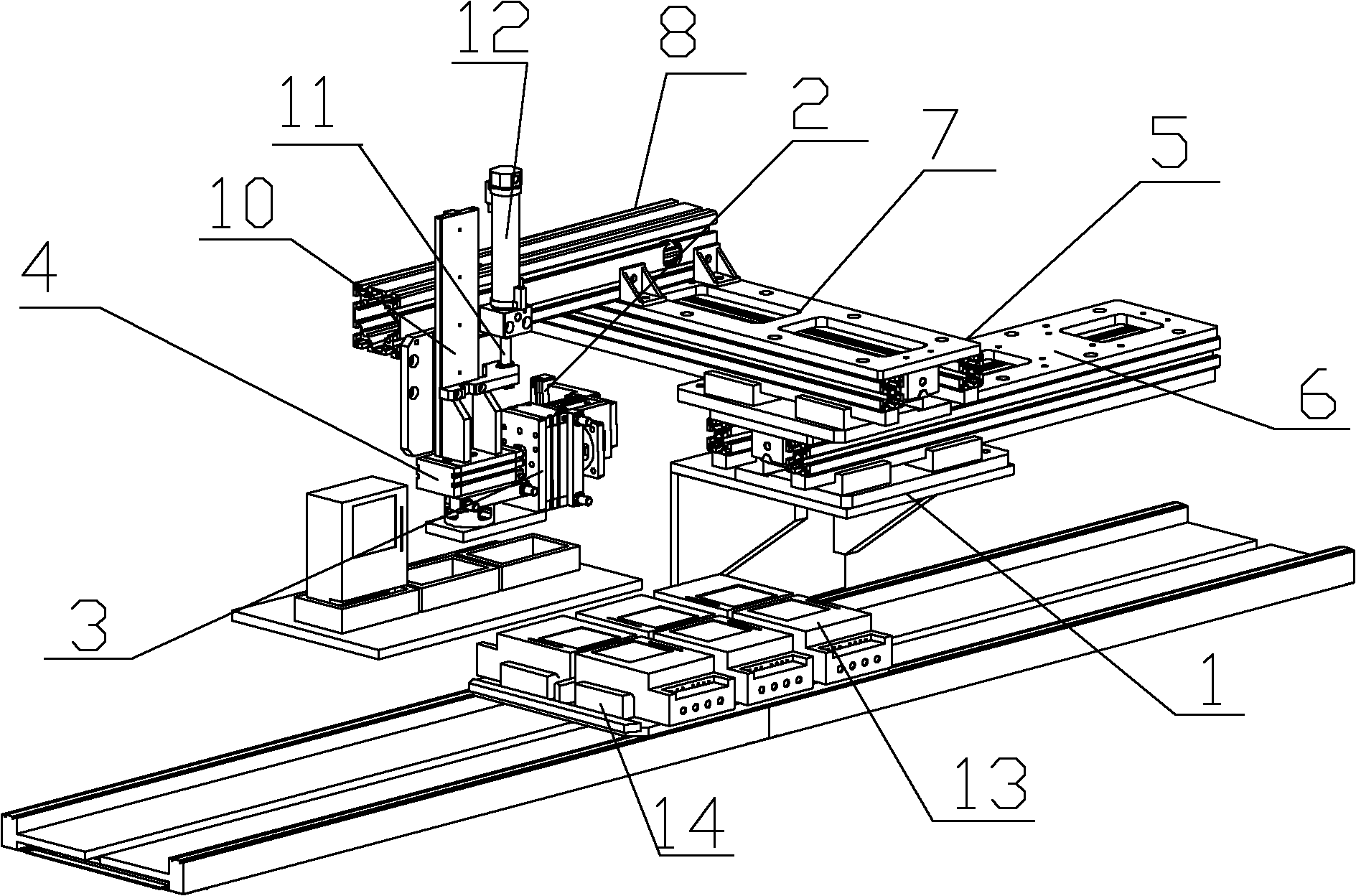

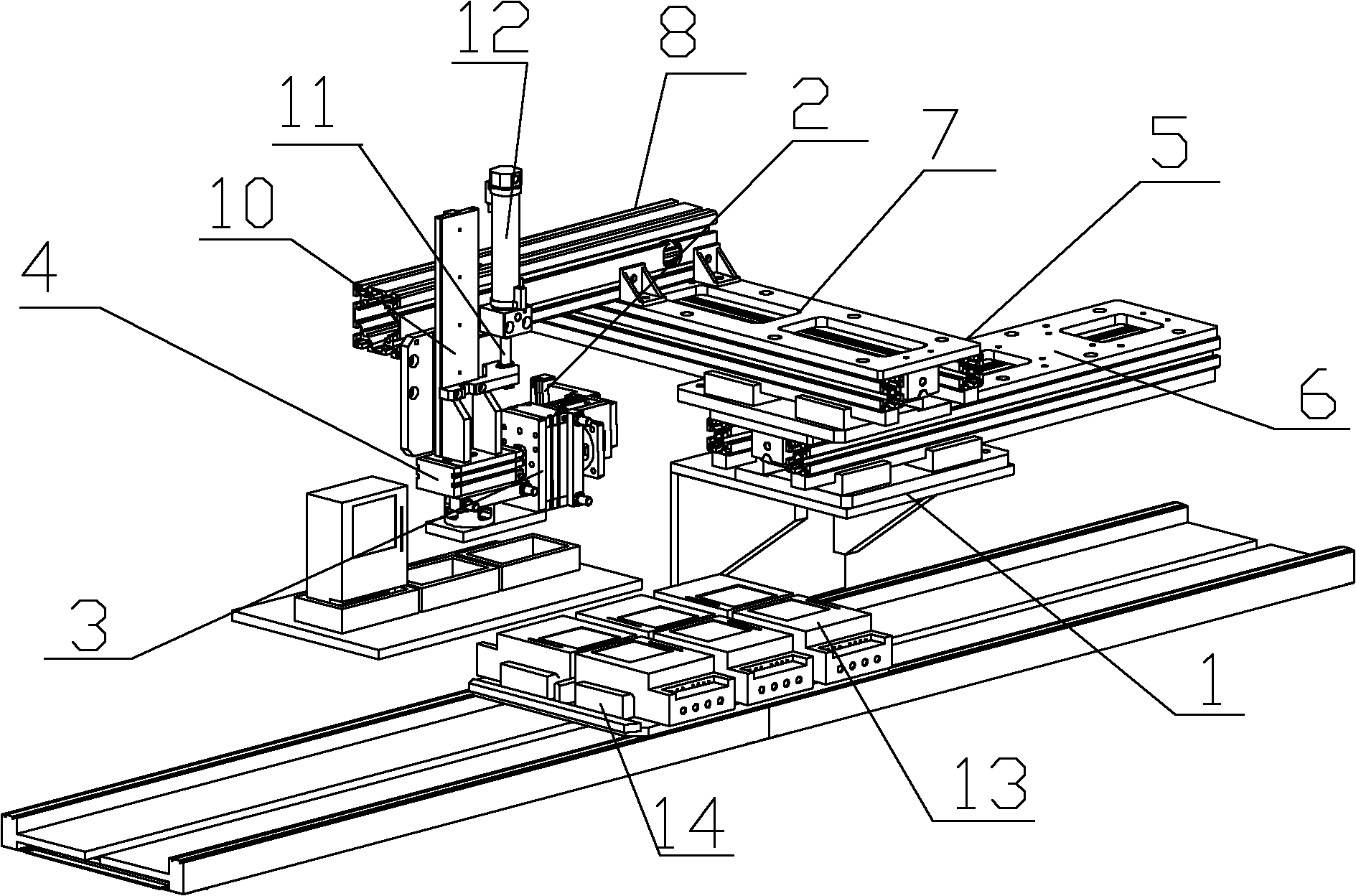

[0016] Such as figure 1 As shown, the electric energy meter handling manipulator described in this embodiment is suitable for multi-meter tooling boards, including a frame 1 and a clamp 2 for clamping the electric energy meter. On the mechanism 3, the vertical electric energy meter 13 can be turned over 90 degrees to be horizontal. The vertical turning mechanism 3 is connected to a horizontal rotation mechanism 4, and the horizontal rotation mechanism 4 can turn the electric energy meter whose direction is inconsistent with the multi-meter position tooling plate 14 13 Rotate 180 degrees, the horizontal rotation mechanism 4 is set on a vertical lifting mechanism 9, the vertical lifting mechanism 9 is connected to a slider 8, and the slider 8 is slidably connected to a "cross" shaped On the horizontal slide table 5, the slide table 5 is slidably connected to the frame 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com