Mobile electronic product metal middle frame and processing technique thereof

A technology for mobile electronics and product metal, applied in the direction of metal shells, casings/cabinets/drawer parts, etc., can solve the problems of high processing costs, poor mass production, low hardness, etc., and achieve fewer machining steps and reduce Effect of weight and hardness increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

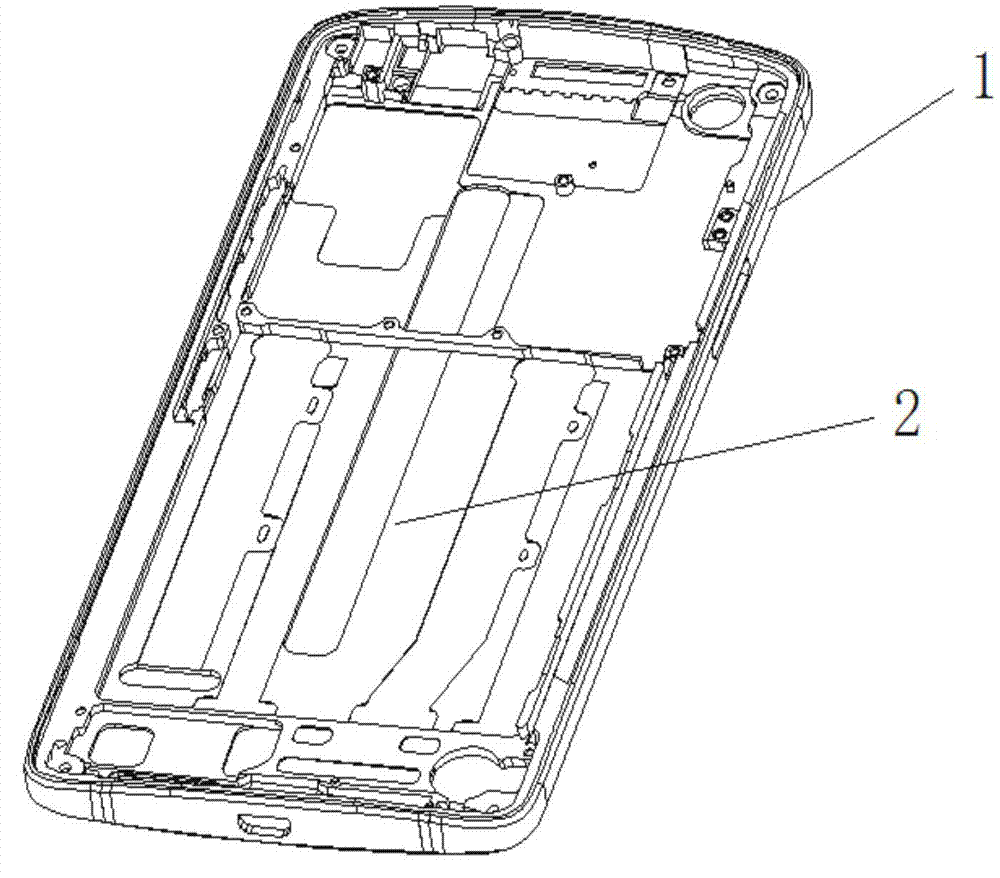

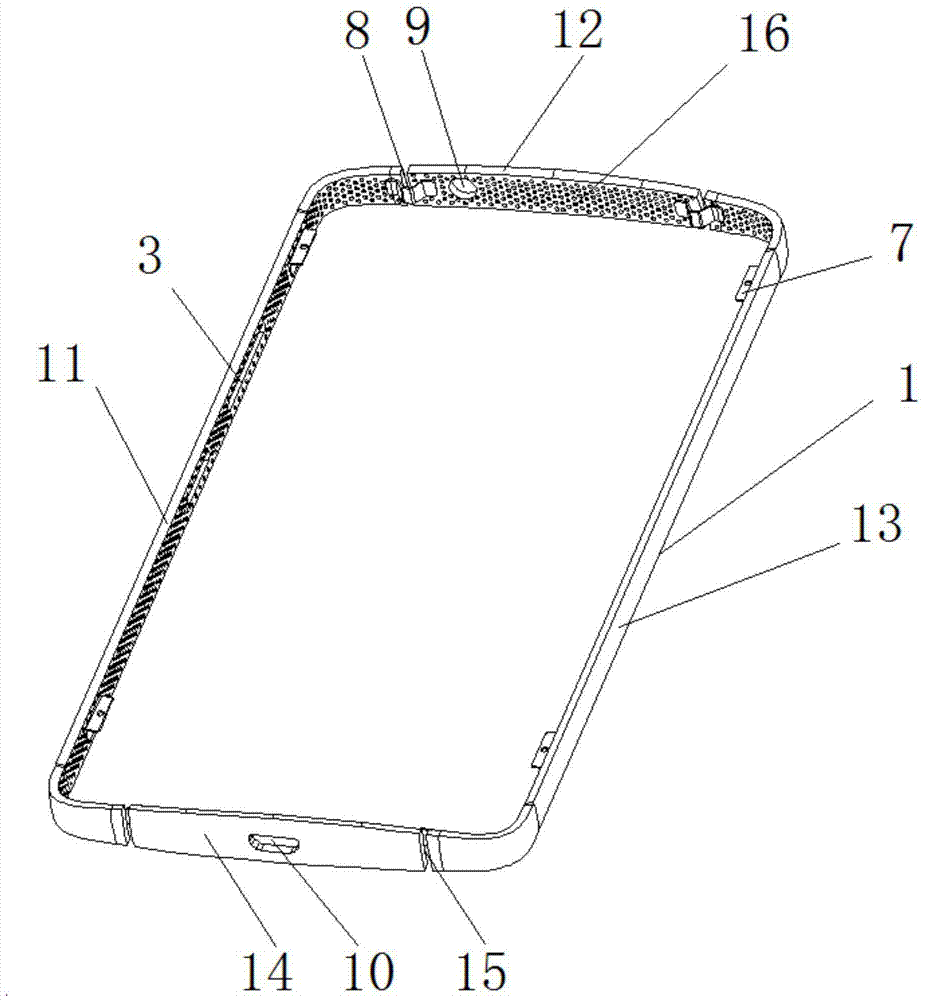

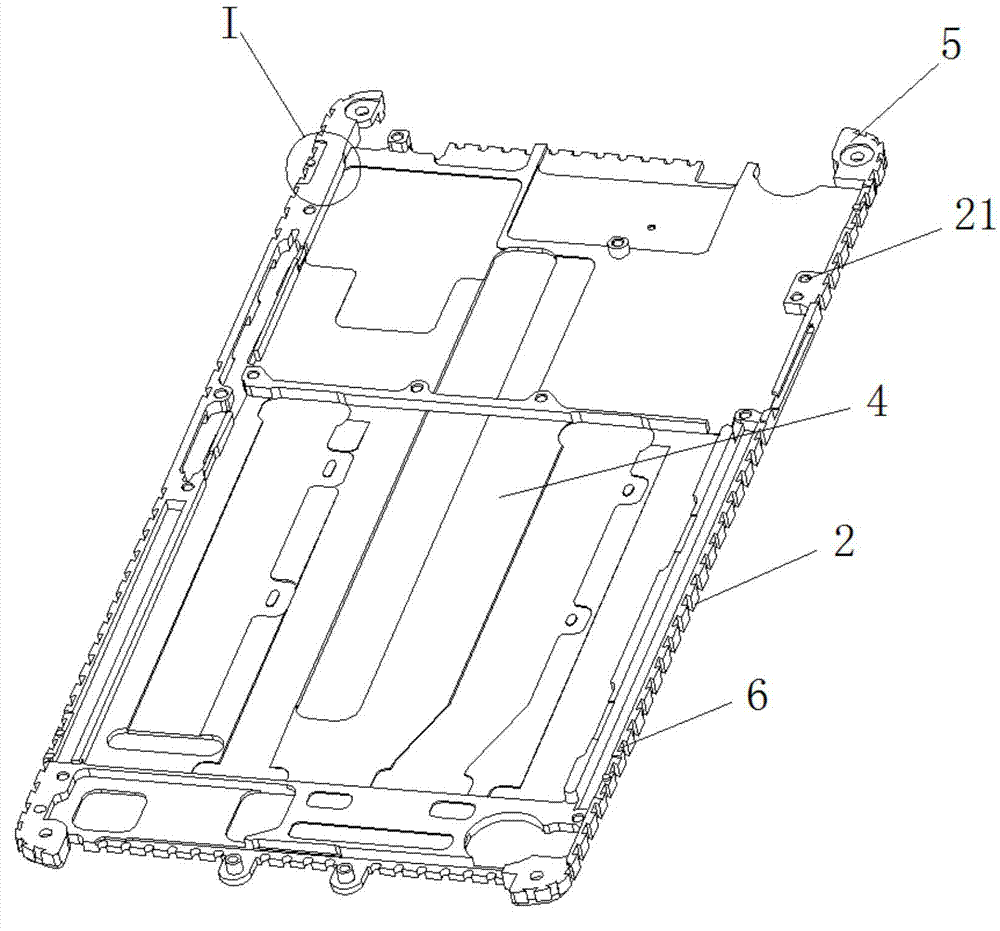

[0038] The invention provides a middle frame of a mobile electronic product, such as figure 1 As shown, the middle frame is made of metal alloy, which includes a frame 1 and a middle plate 2, the middle plate 2 is built in the frame 1, and the frame is made of stainless steel, such as figure 2 , image 3 As shown, in this embodiment, as a preferred solution, the frame 1 includes a first side wall 11, a second side wall 12, a third side wall 13, and a fourth side wall 14 arranged in sequence. Of course, the frame 1 is not limited to The four side walls can be increased or decreased accordingly according to the situation, wherein the first side wall 11 is provided with a number of button holes 3, the number of the button holes in this embodiment is two, and the size of the two button holes It can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com