Lightweight flexible sulfur electrode, and preparation method and application thereof

A sulfur electrode and flexible technology, applied in the field of new batteries, can solve the problems of non-lightweight, highly flexible, thin-film and highly active electrodes, carbon materials with insignificant catalytic effect, and adsorption of polysulfides, etc., to improve the conversion reaction Speed, improve electrochemical performance, improve the effect of interfacial binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A certain area (3cm × 3cm) of carbon nanotube film is immersed in the bath, the plating solution is 25mg / mL copper pyrophosphate solution, which contains 5mg / mL complexing agent potassium pyrophosphate and 1mg / mL auxiliary complexing agent citric acid , the pH of the plating solution is about 8.5; at a temperature of 40°C and a current density of 1.7mA / cm 2Plating for 10min under the condition of the above, and then take out the film and wash it with deionized water to obtain a copper-plated carbon nanotube film.

[0035] Weigh sublimated sulfur, acetylene black and sodium carboxymethylcellulose respectively according to the mass ratio of 8:1:1, and obtain uniformly dispersed powder by stirring, and adjust the solid content of the slurry by adding deionized water (solid content control within 30%), then the slurry is coated with the surface of the carbon nanotube film after copper plating, and placed in a 65°C oven to bake for 12h, finally obtaining a composite of sulfu...

Embodiment 2

[0038] A certain area (3cm × 3cm) of carbon nanotube film is immersed in the bath, the plating solution is 25mg / mL copper pyrophosphate solution, which contains 5mg / mL complexing agent potassium pyrophosphate and 1mg / mL auxiliary complexing agent citric acid , the pH of the plating solution is about 8.5; at a temperature of 40°C and a current density of 1.7mA / cm 2 Plating for 10min under the condition of the above, and then take out the film and wash it with deionized water to obtain a copper-plated carbon nanotube film.

[0039] Weigh sublimated sulfur, acetylene black and sodium carboxymethylcellulose respectively according to the mass ratio of 8:1:1, and obtain uniformly dispersed powder by stirring, and adjust the solid content of the slurry by adding deionized water (solid content control within 30%), then the slurry is coated with the surface of the carbon nanotube film after copper plating, and placed in a 65°C oven to bake for 12h, finally obtaining a composite of sulf...

Embodiment 3

[0042] The graphene thin film of certain area (3cm * 3cm) is immersed in the bath, and plating bath is 25mg / mL copper pyrophosphate solution, wherein contains 5mg / mL complexing agent potassium pyrophosphate and 1mg / mL auxiliary complexing agent citric acid, The pH of the bath is about 8.5. At a temperature of 40°C and a current density of 1.8mA / cm 2 Plating under the conditions of 10min, and then remove the film and rinse with deionized water.

[0043] Weigh sublimated sulfur, acetylene black and sodium carboxymethylcellulose respectively according to the mass ratio of 8:1:1, and obtain uniformly dispersed powder by stirring, and adjust the solid content of the slurry by adding deionized water (solid content control within 30%), then the slurry is coated with the surface of the copper-plated graphene film, and placed in a 65°C oven to bake for 12h to finally obtain a composite sulfur positive electrode of sulfur carbon / copper sulfide / copper-graphene film .

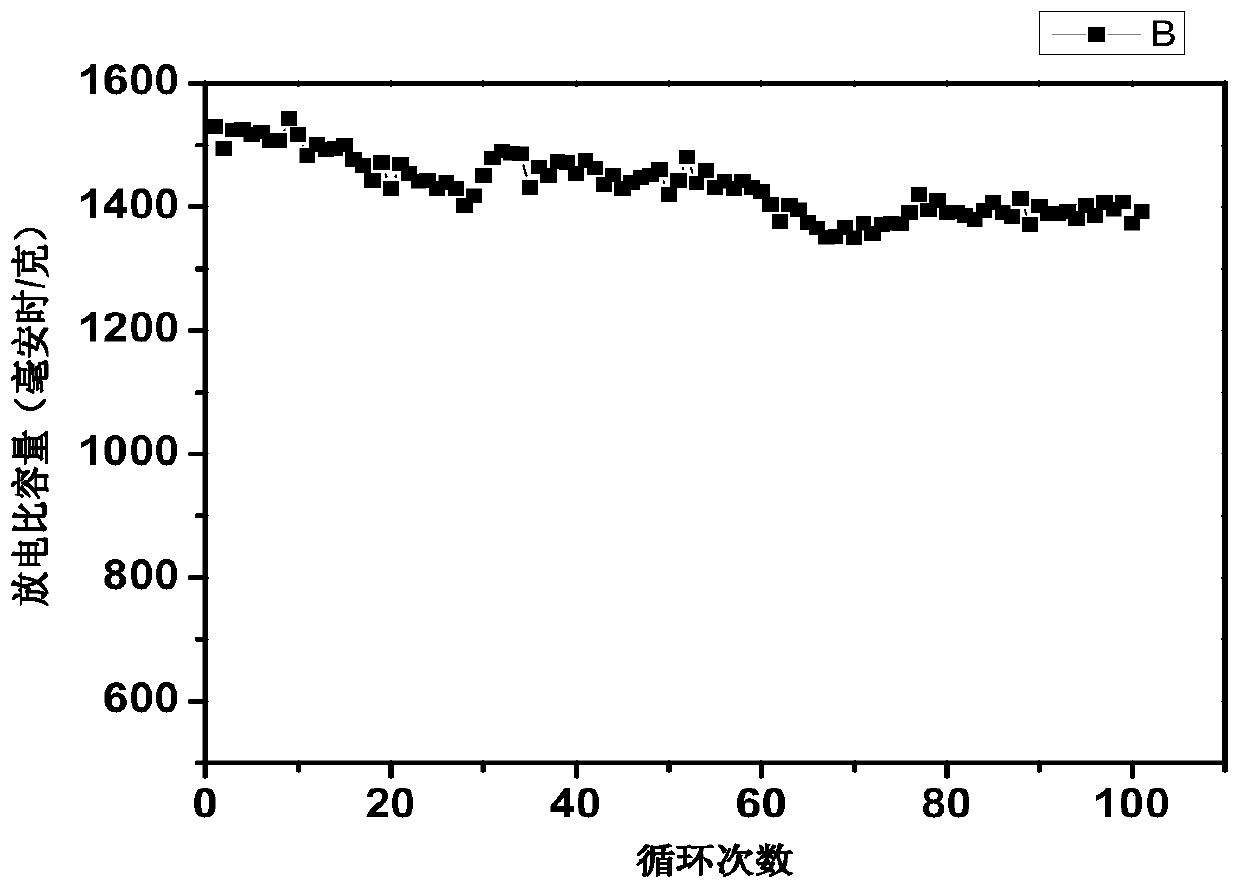

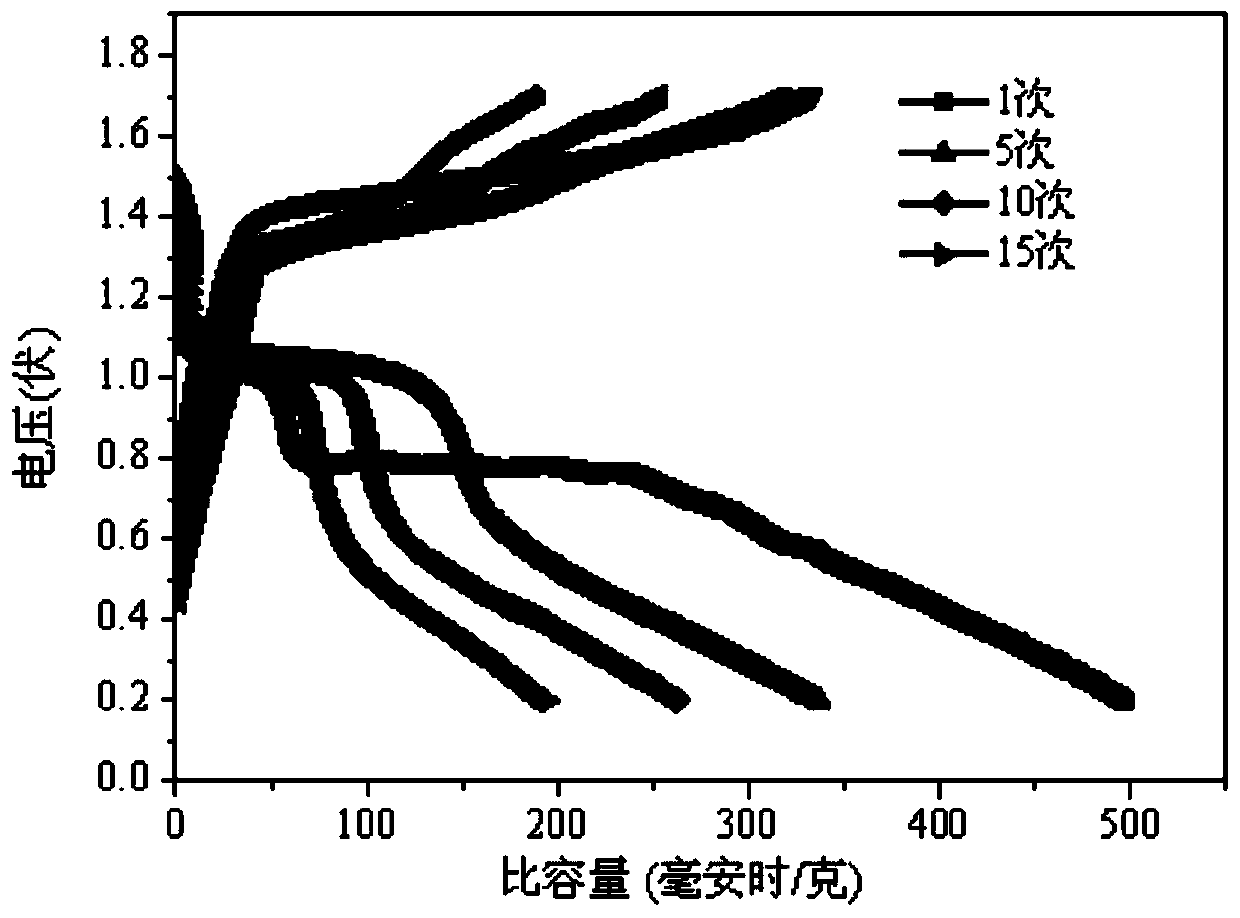

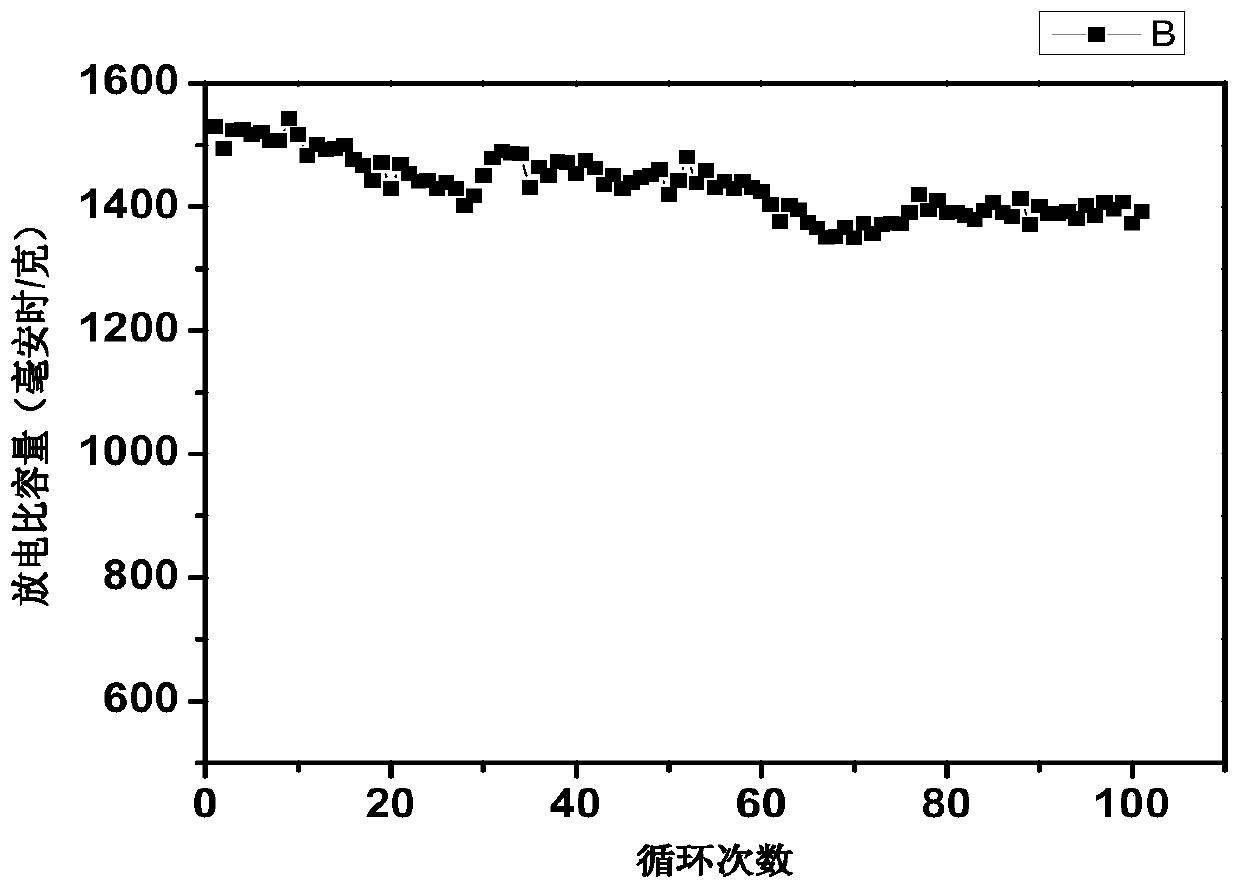

[0044] The obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com